Preparation method of microcapsuled red phosphorus for polyurethane resin

A technology for microencapsulating red phosphorus and polyurethane resin, which is applied in the directions of microcapsule preparation, microsphere preparation, etc., can solve the problem that red phosphorus cannot be directly added, and achieves the effect of less addition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

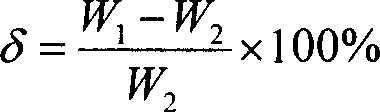

[0039] First red phosphorus pretreatment. Soak 100g of crude red phosphorus in 50g of 30% glycerol aqueous solution for 12h, grind it twice with a colloid mill, filter, wash the filter cake with absolute ethanol three times, and dry it in an oven at 80°C to constant weight for later use.

[0040] 40 g of the above-mentioned treated red phosphorus, 55 g of water, and 2.6 g of polyethylene glycol were made into an aqueous suspension emulsion, and after being ground twice in a colloid mill, it was moved into a 250 ml three-necked bottle, and 80 g of chloroform was added at a stirring speed of 2000 rpm , Stir for 60min to form a milky solution. Reduce stirring speed to 200rpm, temperature is 5~10 ℃, add 22.4g diphenylmethane diisocyanate solution (wherein diphenylmethane diisocyanate: Tween-80: trichloromethane is 2: 0.4: 20), maintain temperature and Stir at a constant speed, react for 30 minutes, filter, wash with chloroform and water three times, and dry at 50°C to constant we...

Embodiment 2

[0054] Red phosphorus 60g pretreated in the same way as in Example 1 was made into an aqueous suspension emulsion with 38g water and 1.6g ethylenediamine, and after being ground twice in a colloid mill, it was moved into a 250ml three-necked bottle, and at a stirring speed of 1000rpm, adding 70g of cyclohexanone was stirred for 60min to form a milky solution. Reduce the stirring speed to 400rpm, the temperature is 3~10°C, add 30.4g diphenylmethane diisocyanate solution (wherein diphenylmethane diisocyanate: sodium dodecylbenzenesulfonate: cyclohexanone is 10:0.4:20 ), keep the temperature and stirring speed constant, react for 30min, filter, wash with water three times, and dry to constant weight at 50°C to obtain microencapsulated red phosphorus.

[0055] According to the method introduced in Example 1, various indicators were measured: coating rate: 17%; moisture absorption rate: 0.050%; ignition point: 375° C.; phosphine release: 0.21 μg / g·24h.

Embodiment 3

[0057] Red phosphorus 80g pretreated in the same way as in Example 1 was made into an aqueous suspoemulsion with 31g water and 4.6g polyvinyl alcohol. After grinding twice in a colloid mill, move it into a 250ml three-necked bottle, and at a stirring speed of 4000rpm, add Carbon tetrachloride 60g, stirred for 60min, into a milky solution. Reduce the stirring speed to 400rpm, the temperature is 3 ~ 10 ℃, add 24.4g diphenylmethane diisocyanate solution (wherein diphenylmethane diisocyanate: sodium oleate: carbon tetrachloride is 4: 0.4: 20), maintain the temperature With constant stirring speed, the reaction was carried out for 30 minutes, filtered, washed with water three times, and dried at 50°C to constant weight to obtain microencapsulated red phosphorus.

[0058] According to the method introduced in Example 1, various indicators were measured: coating rate: 10%; moisture absorption rate: 0.021%; ignition point: 355° C.; phosphine release: 0.15 μg / g·24h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com