Anisotropic conductive film

a conductive film and anisotropic technology, applied in the direction of non-metal conductors, connection contact materials, conductors, etc., can solve the problems of increased costs, waste of combination of a faulty electronic component and a good circuit board, and difficulty in fine pitch connection with the connection target, etc., to achieve good electrical continuity and low load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

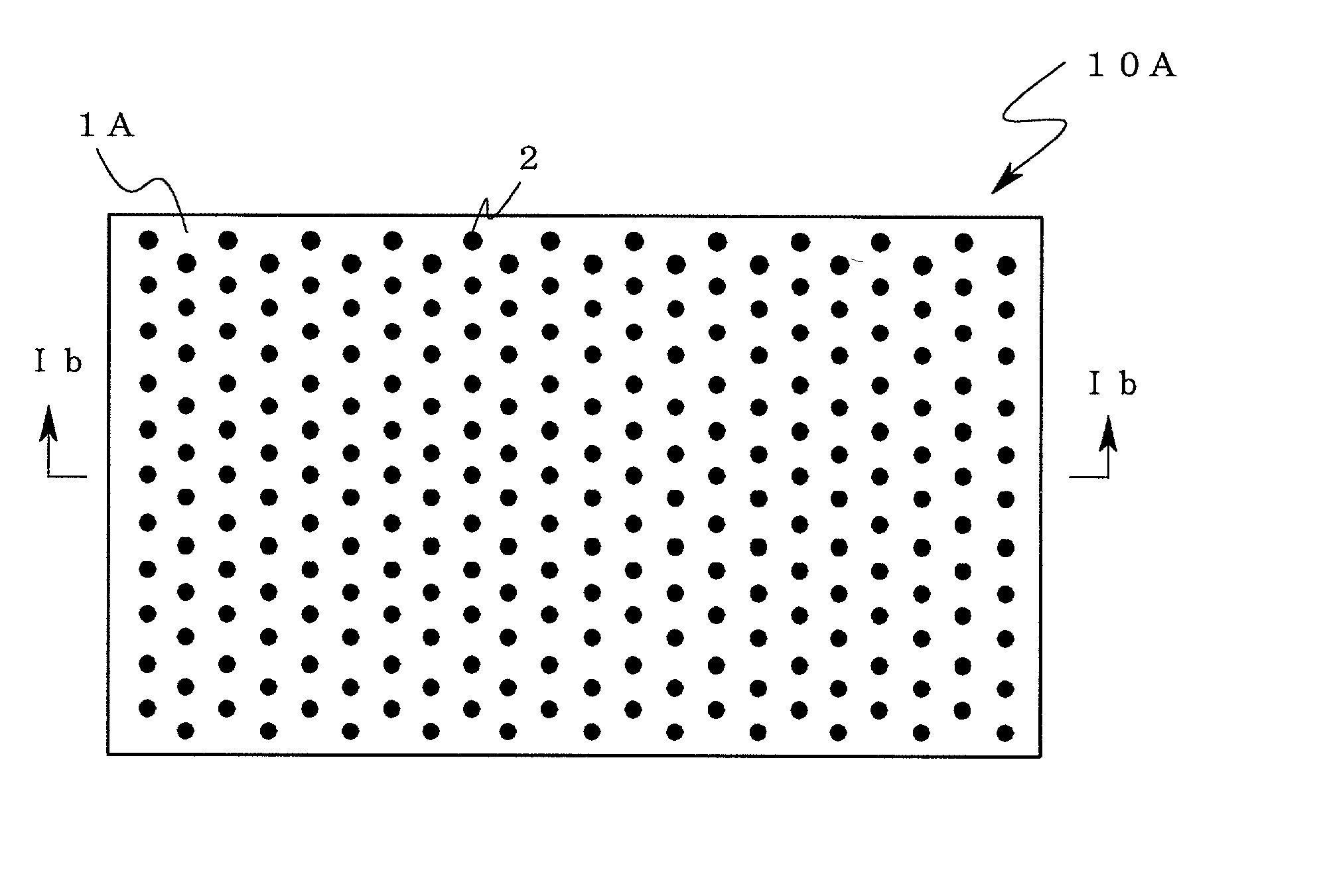

first embodiment

[0036] As described above, when a conventional anisotropic conductive film employing a polycarbodiimide resin for the film substrate 1A is used as a mounting connector, connection targets (electronic component and circuit board) cannot be connected satisfactorily (joined firmly to provide electrical continuity) unless the anisotropic conductive film is heated to a temperature of 250.degree. C. or higher for thermal compression bonding. On the other hand, when the anisotropic conductive film of the present invention is used, the film substrate 1A softens or melts sufficiently upon heating at a low temperature of about 150 to 200.degree. C. so that a good connection can be achieved between said film and the subjects of connection. In addition, because the film substrate 1A possesses favorably low water absorption derived from the polycarbodiimide resin, the finished product obtained by mounting (e.g., a semiconductor device wherein a semiconductor element is mounted on a circuit board...

second embodiment

[0069] The anisotropic conductive film of the present invention is hereinafter described.

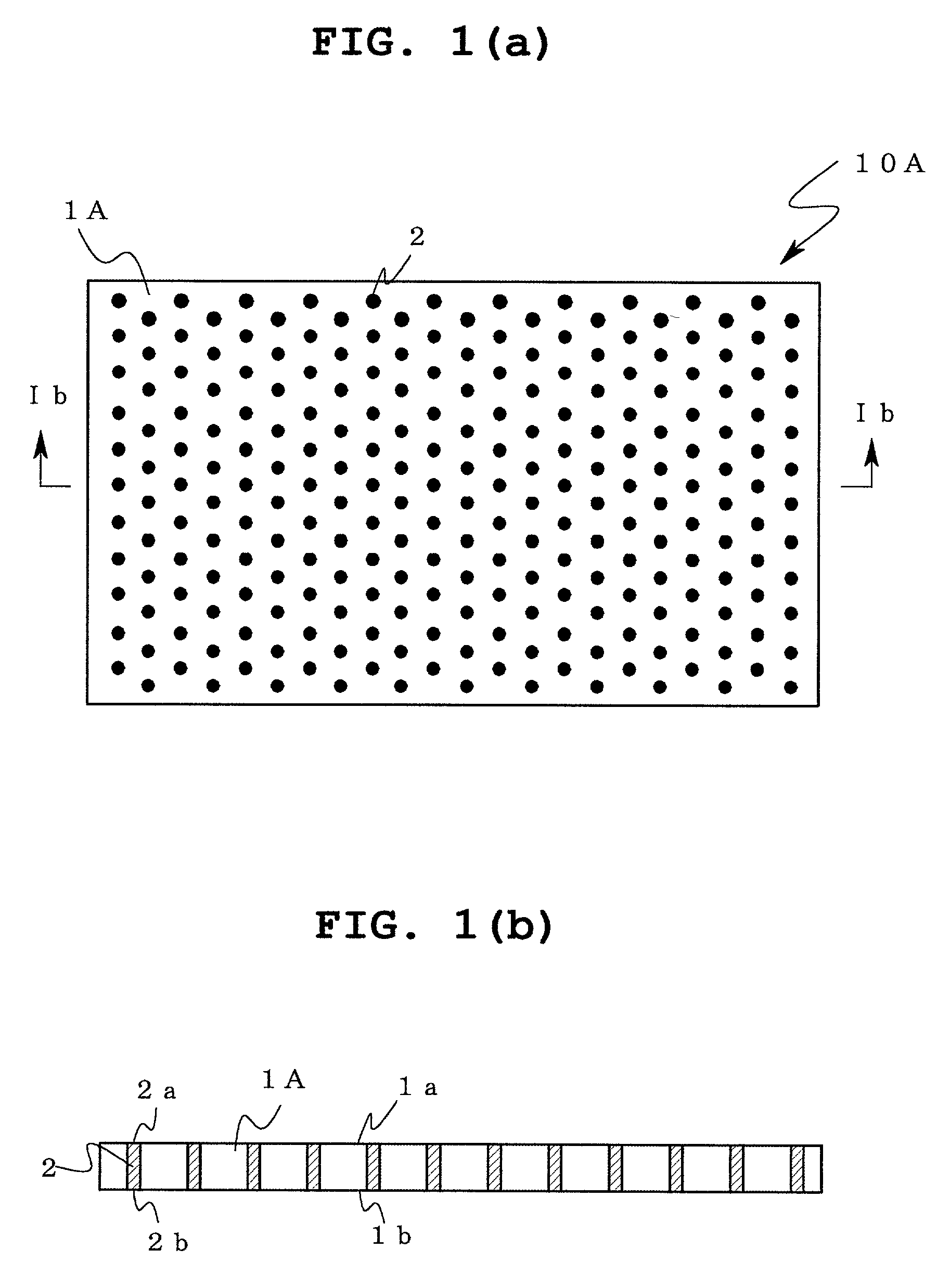

[0070] FIG. 4 shows an example of the anisotropic conductive film of the second embodiment of the present invention, i.e., an anisotropic conductive film especially useful as a testing connector. FIG. 4(a) is a plan view, and FIG. 4(b) is a cross-sectional view along the line IVb-IVb in FIG. 4(a). The anisotropic conductive film of the second embodiment of the present invention, as represented by this anisotropic conductive film 10B in FIG. 4, has a plurality of conductive paths 2 insulated from each other in the film substrate 1B comprising an insulating resin and penetrating the film substrate 1B in the direction of the thickness of the film substrate 1B, both ends 2a and 2b of each conductive path 2 being exposed to the top and back faces 1a and 1b, respectively, of the film substrate 1B, wherein the film substrate 1B is mainly composed of a setting product of the polycarbodiimide copolymer o...

example 1

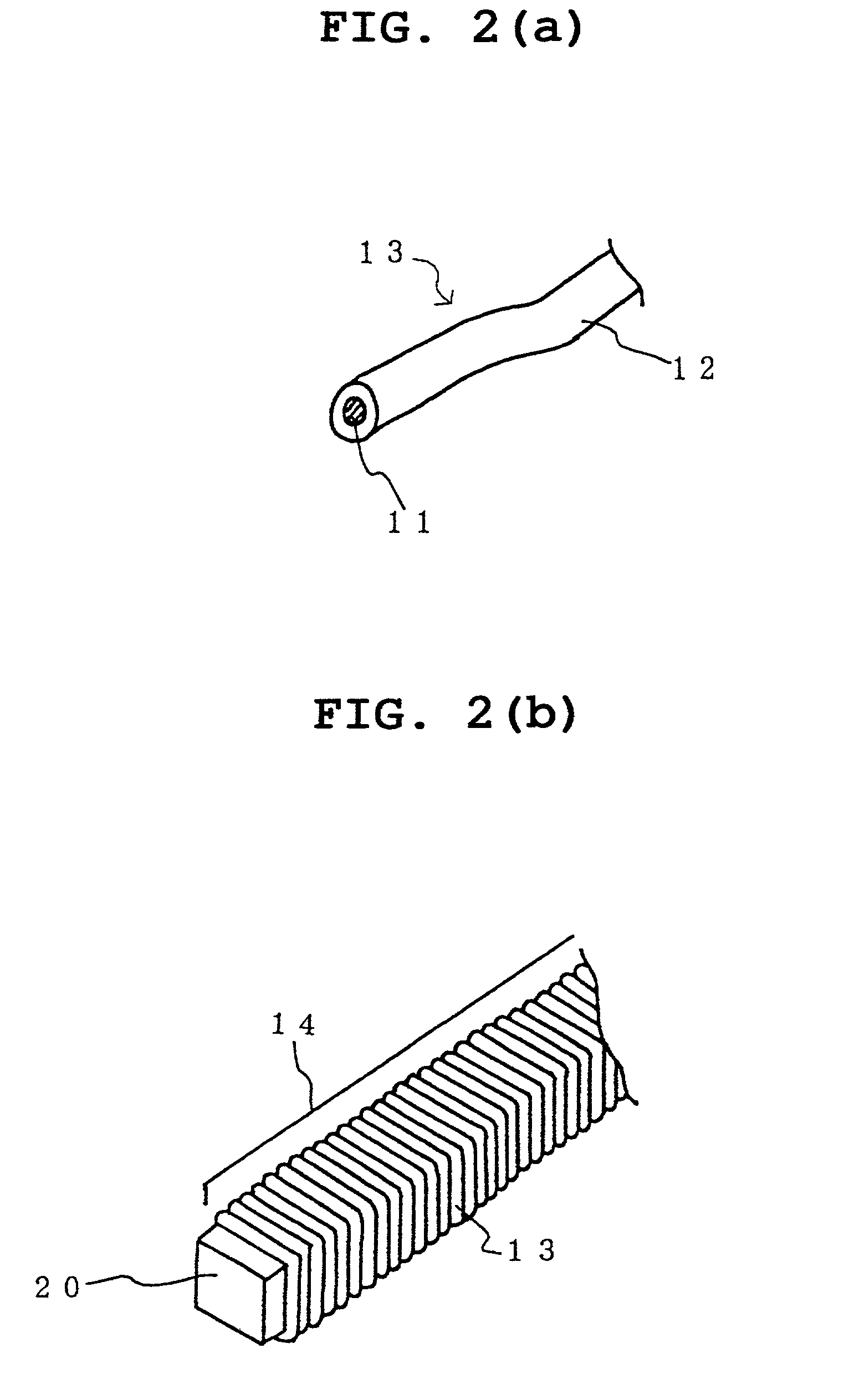

[0088] A mixture (100 g) of tolylene diisocyanate (2,4-tolylene diisocyanate (2,4-TDI) and 2,6-tolylene diisocyanate (2,6-TDI) (2,4-TDI:2,6-TDI=2:8 (molar ratio)) and polyhexamethylene carbonate diol (100 g) were urethanized by a reaction in a mixed solvent (100 g) of xylene and cyclohexane at 100.degree. C. for 3 hours. Subsequently, 3-methyl-1-phenyl-2-phosphorene-1-oxide (0.883 g) and p-isopropylphenyl isocyanate (6.47993 g) were added, and this was followed by polymerization at 100.degree. C. for 1 hour to yield a solution of a polycarbodiimide copolymer resulting from copolymerization of polyhexamethylene carbonate. This solution was dried at 90.degree. C. for 30 minutes and at 200.degree. C. for 30 minutes to yield a film, and the polycarbodiimide copolymer was collected as a solid. The glass transition temperature of this solid was determined to be 130.degree. C. The number-average molecular weight of this solid was determined to be 6300.

[0089] An insulated lead wire was prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com