Sensor arrays for detecting analytes in fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

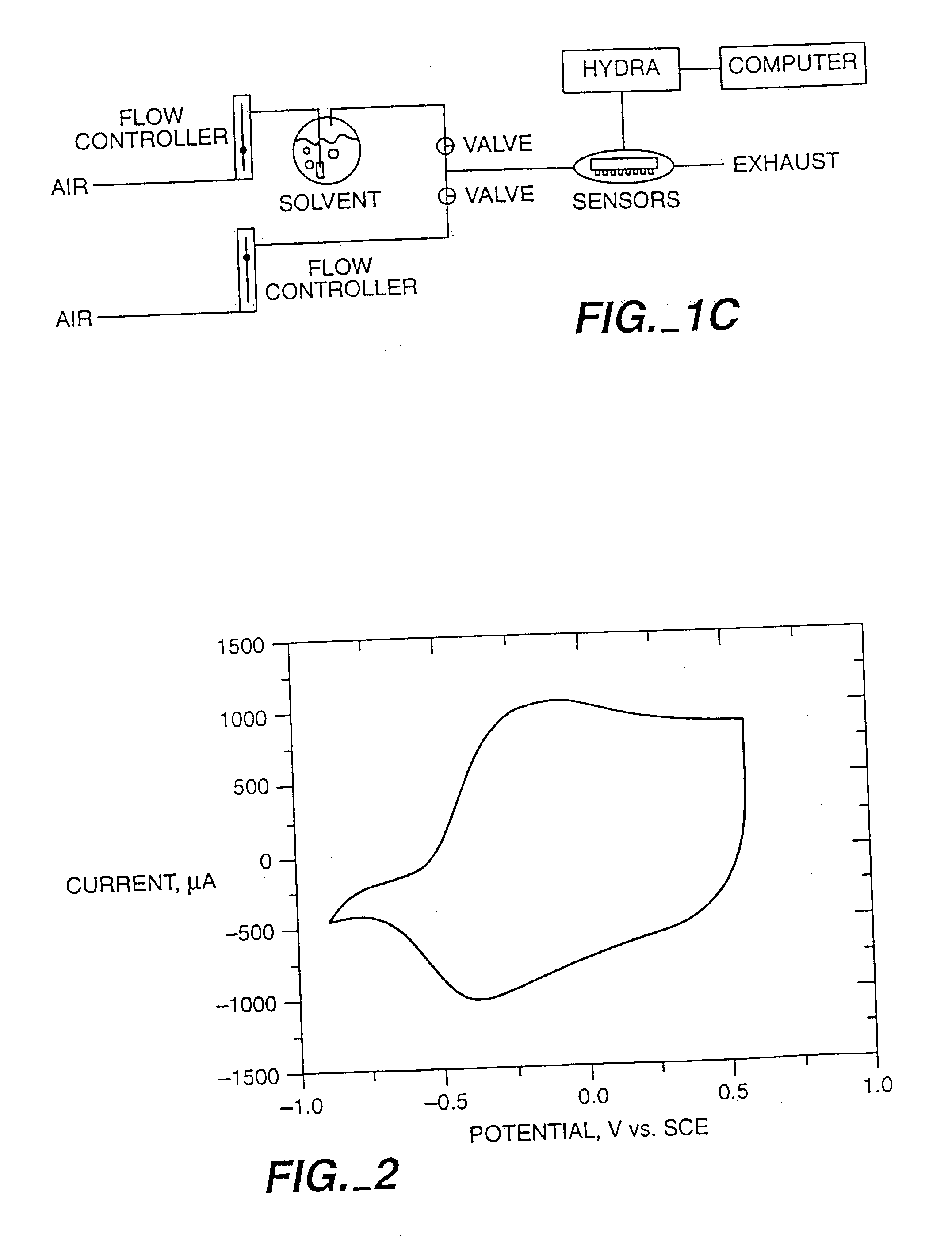

[0035] Polymer Synthesis. Poly(pyrrole) films used for conductivity, electrochemical, and optical measurements were prepared by injecting equal volumes of N.sub.2-purged solutions of pyrrole (1.50 mmoles in 4.0 ml dry tetrahydrofuran) and phosphomolybdic acid (0.75 mmoles in 4.0 ml tetrahydrofuran) into a N.sub.2-purged test tube. Once the two solutions were mixed, the yellow phosphomolybdic acid solution turned dark green, with no observable precipitation for several hours. This solution was used for film preparation within an hour of mixing.

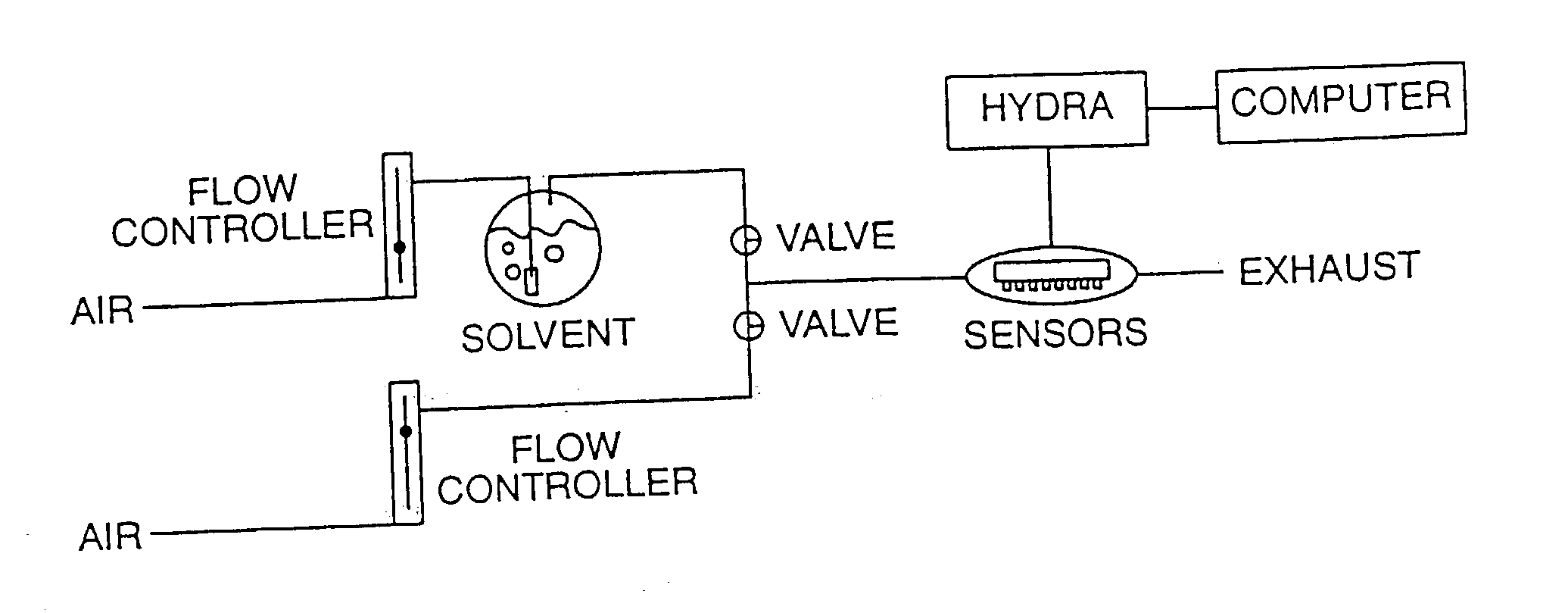

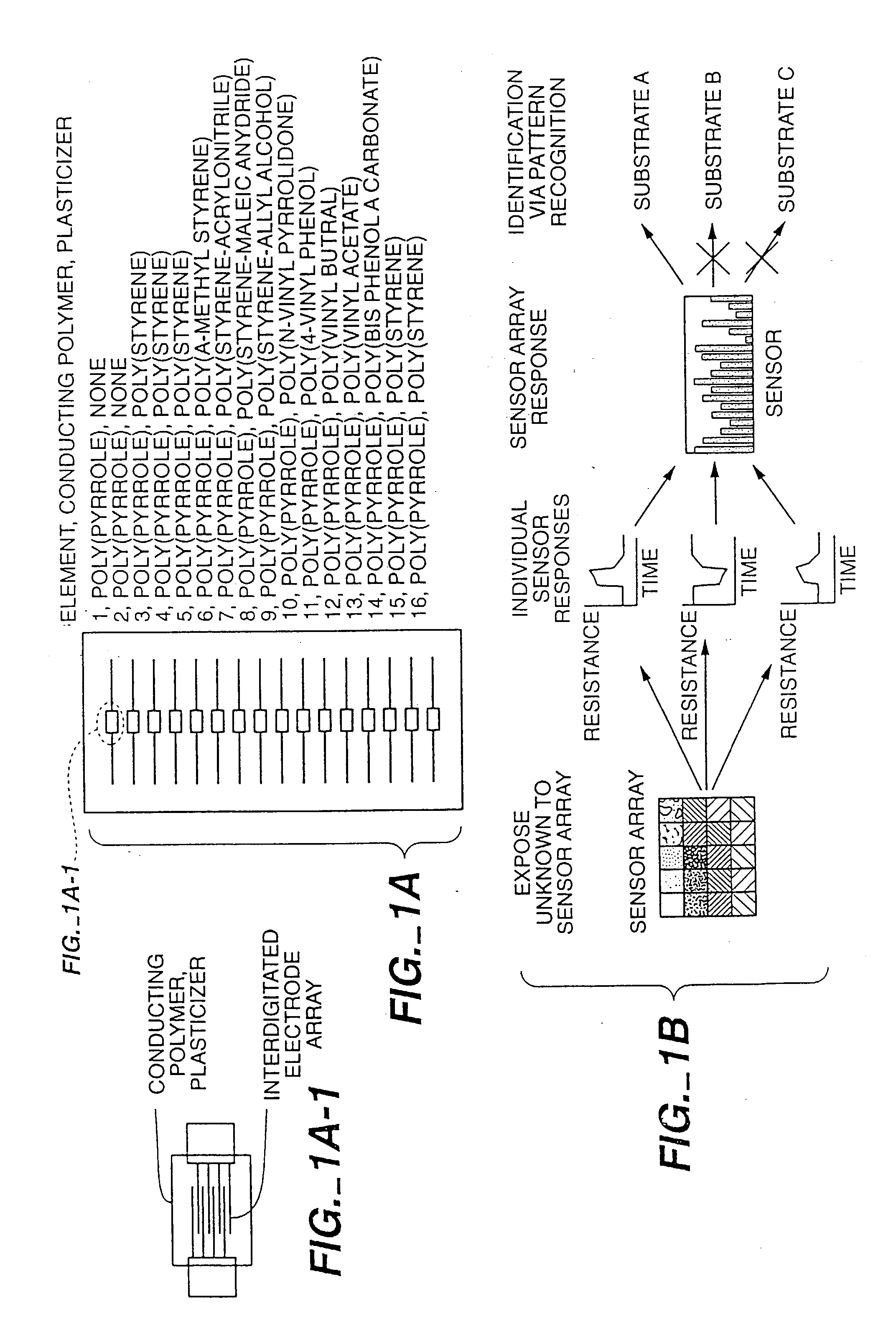

[0036] Sensor Fabrication. Plasticized poly(pyrrole) sensors were made by mixing two solutions, one of which contained 0.29 mmoles pyrrole in 5.0 ml tetrahydrofuran, with the other containing 0.25 mmoles phosphomolybdic acid and 30 mg of plasticizer in 5.0 ml of tetrahydrofuran. The mixture of these-two solutions resulted in a w:w ratio of pyrrole to plasticizer of 2:3. An inexpensive, quick method for crating the chemiresistor array elements w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com