Sustained release matrix systems for highly soluble drugs

a matrix system and drug technology, applied in the direction of drug compositions, non-active ingredients of oil/fat/waxes, cardiovascular disorders, etc., can solve the problems of variable drug release, soluble to highly soluble drugs present formulation difficulties, sustained release formulations with soluble drugs are susceptible to "dose dumping"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

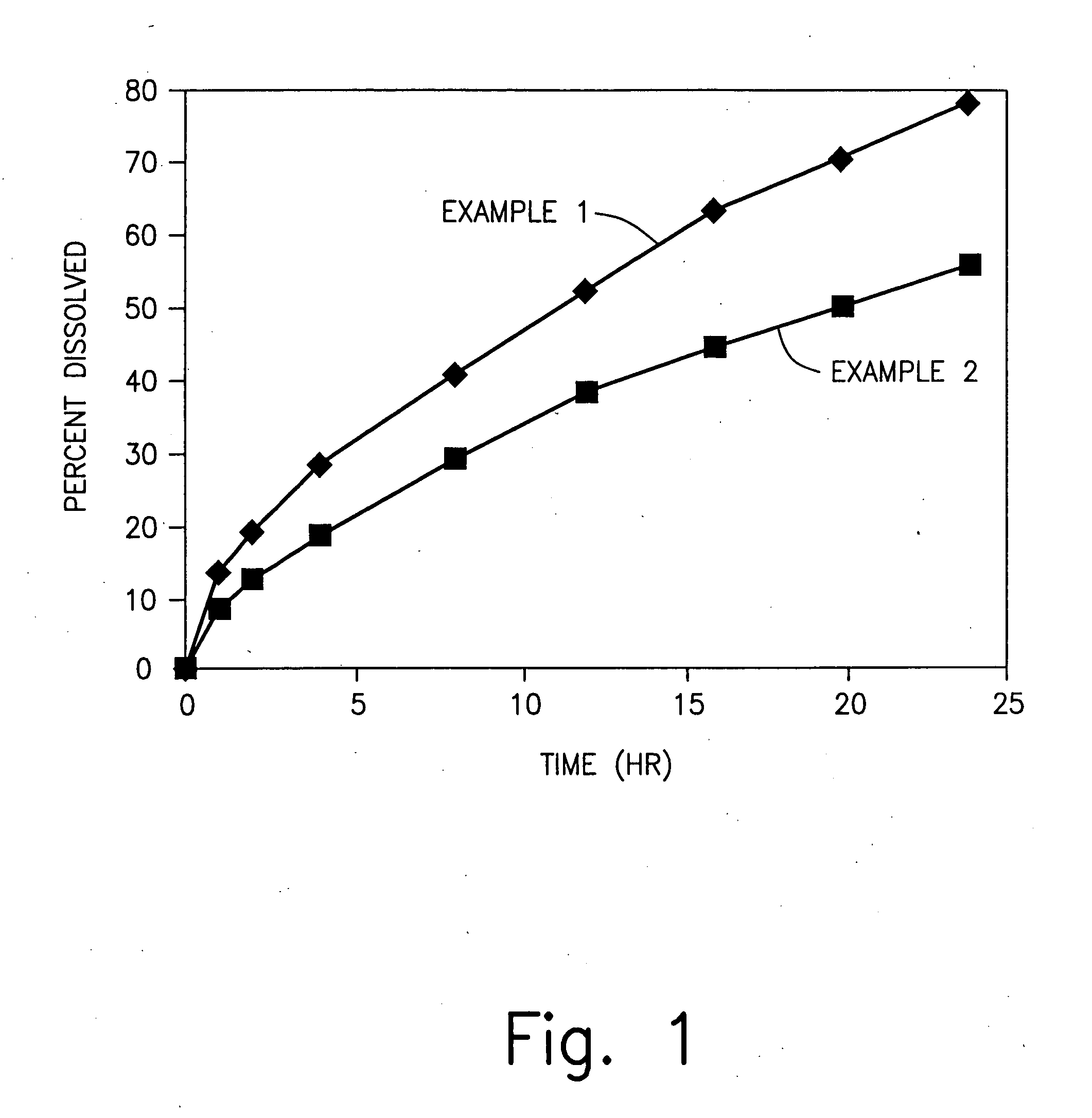

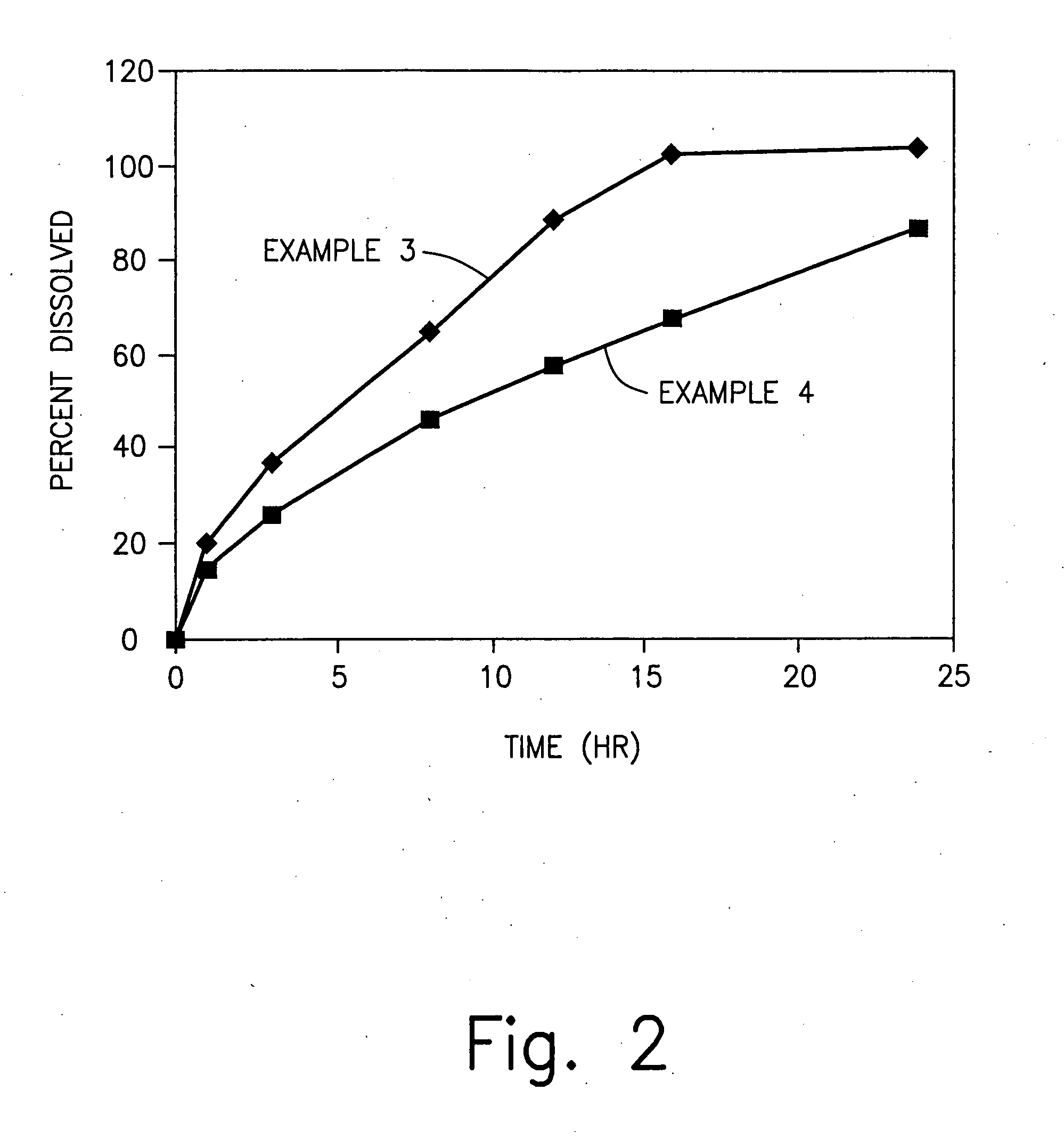

examples 3-4

Effect of Gum:Dextrose Ratio

[0127] In Examples 3-4, a sustained release excipient is prepared in accordance with the procedure set forth in Examples 1 and 2. The ingredients of the sustained release excipient of Examples 3 and 4 are set forth in table 4 below:

4TABLE 4 Component Amount (%) - Ex. Amount (%) -Ex. 2 1 Xanthan Gum 12 20 2 Locust Bean Gum 18 30 3 Dextrose 70 50 4 Water* 25 35 *removed during processing

[0128] Thereafter, diltiazem tablets are prepared as follows:

[0129] The desired amount of diltiazem, fumaric acid and the sustained release excipient are placed in a granulator and mixed for 3 minutes at low speed. Water is added over a 2 minute interval while the impeller is running at low speed (additional water and granulation time may be used to form proper granules). The resultant granules are then dried in a fluid bed dryer until LOD is less than 5% and milled with hammer forward at 2000-3000 rpm using screen #0050. The milled granulation is then placed in a V-Blender ...

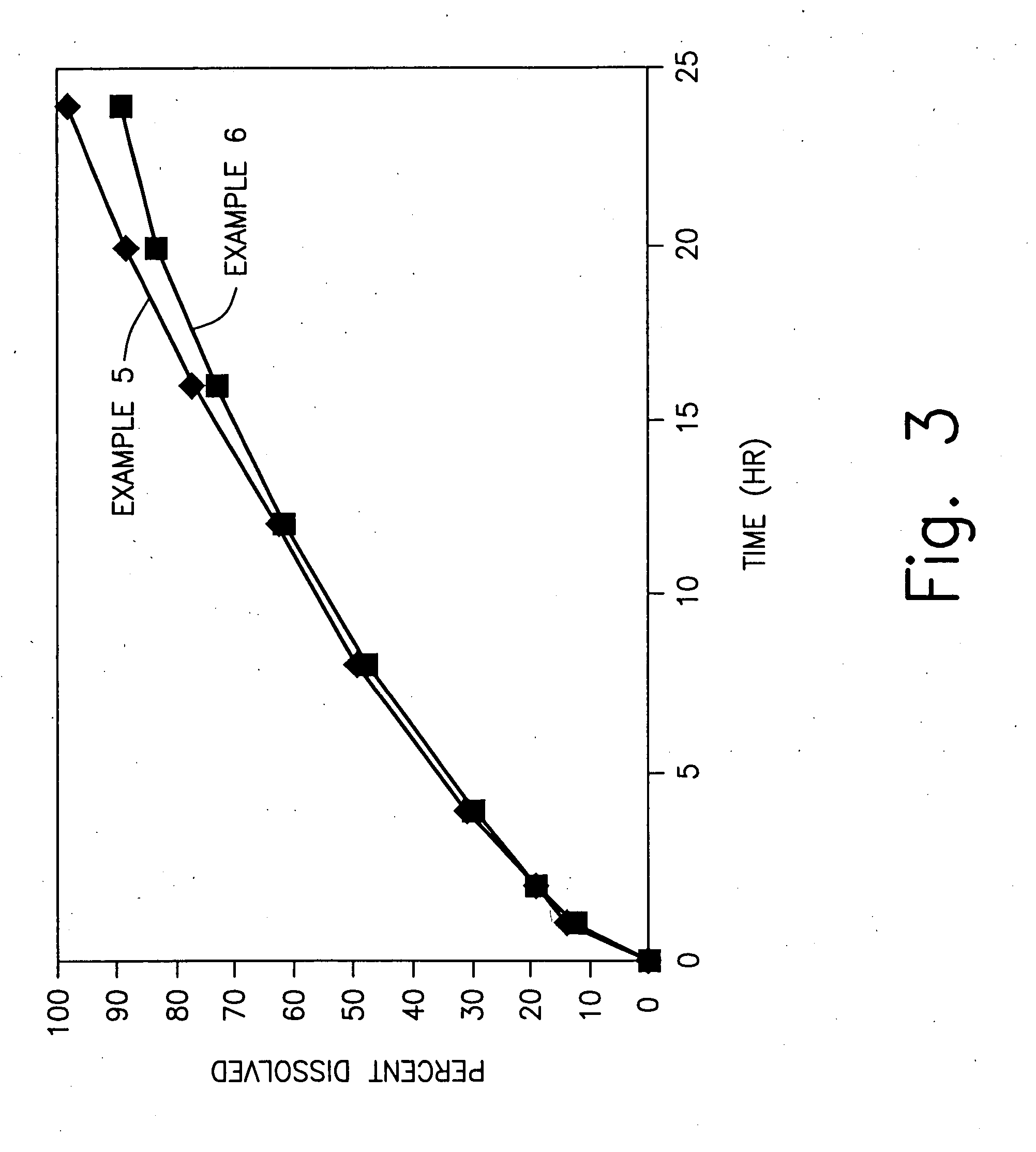

examples 5-6

Effect of Surfactant Type

[0133] In Examples 5-6, a sustained release excipient is prepared accordance with the procedure set forth in Examples 1 and 2. The ingredients of the sustained release excipient of Examples 5 and 6 are set forth in table 7 below:

7 TABLE 7 Component Amount (%) - Ex. 5-6 1 Xanthan Gum 12 2 Locust Bean Gum 18 3 Dextrose 70 4 Water* 25 *removed during processing

[0134] Thereafter, diltiazem tablets are prepared as follow:

[0135] The desired amount of diltiazem, fumaric acid and a suitable amount of water are mixed for 5 minutes with an impeller type mixer to form a slurry. The slurry is then added to the sustained release excipient over a 1 minute interval in the granulator, with the impeller running on low speed. Next, the mixture is granulated for 2 minutes with the chopper and impeller on high speed (additional water and granulation time may be used to form proper granules). The resultant granules are then dried in a fluid bed dryer until LOD is less than 5% an...

examples 7-8

Effect of Surfactant Level

[0140] In Examples 7-8, a sustained release excipient is prepared accordance with the procedure set forth in Examples 1 and 2. The ingredients of the sustained release excipient of Examples 7 and 8 are set forth in table 10 below:

10 TABLE 10 Component Amount (%) - Ex. 7-8 1. Xanthan Gum 12 2. Locust Bean Gum 18 3. Dextrose 70 4. Water* 25 *Removed during processing

[0141] Thereafter, diltiazem tablets are prepared as follows:

[0142] The desired amount of diltiazem, fumaric acid and a suitable amount of water are mixed for 5 minutes with an impeller type mixer to form a slurry. The slurry is then added to sustained release excipient over a 1 minute interval in the granulator, with the impeller running on low speed. Next, the mixture is granulated for 2 minutes with the chopper and impeller on high speed (additional water and granulation time may be used to form proper granules). The resultant granules are then dried in a fluid bed dryer until LOD is less than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility | aaaaa | aaaaa |

| solubility | aaaaa | aaaaa |

| solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com