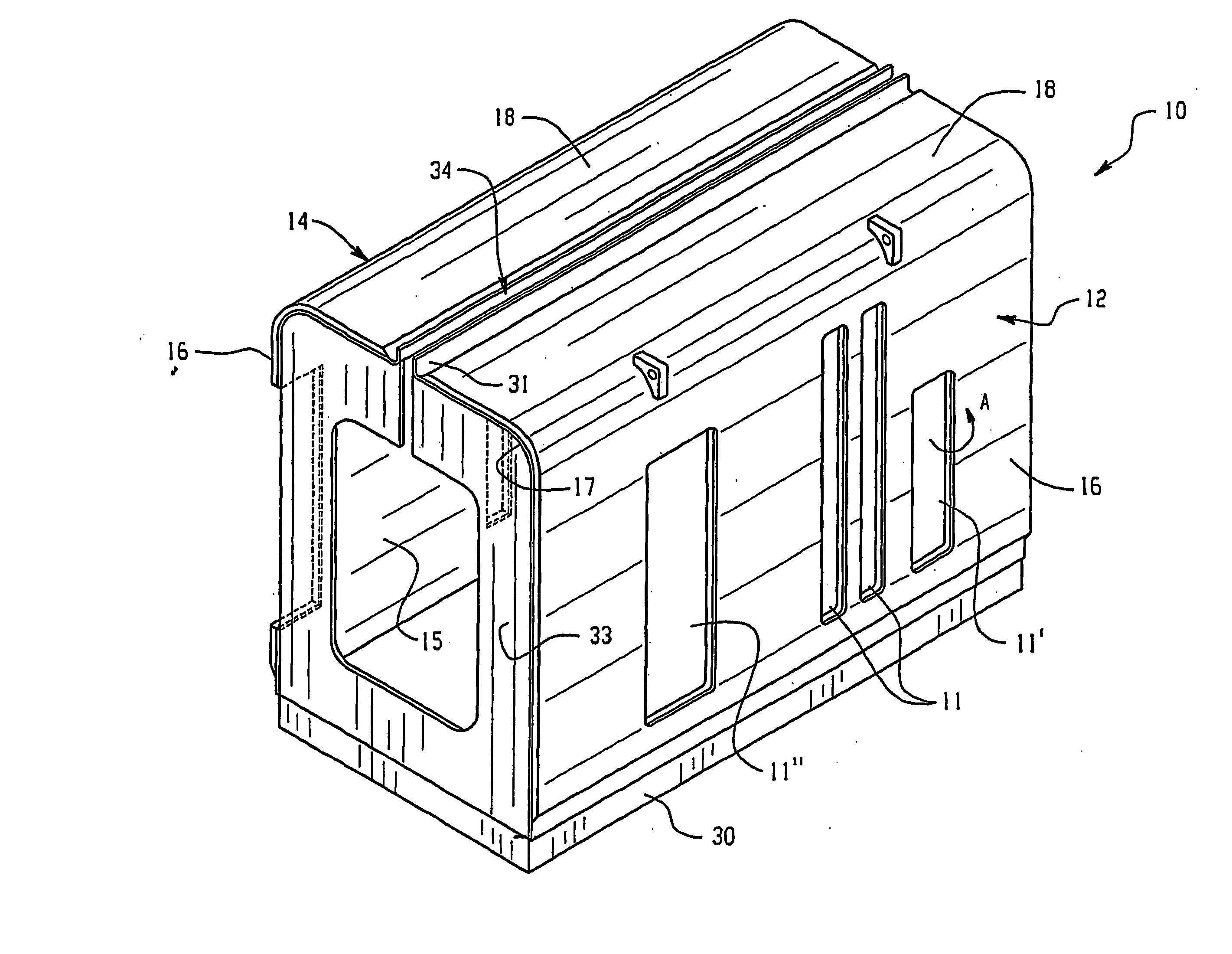

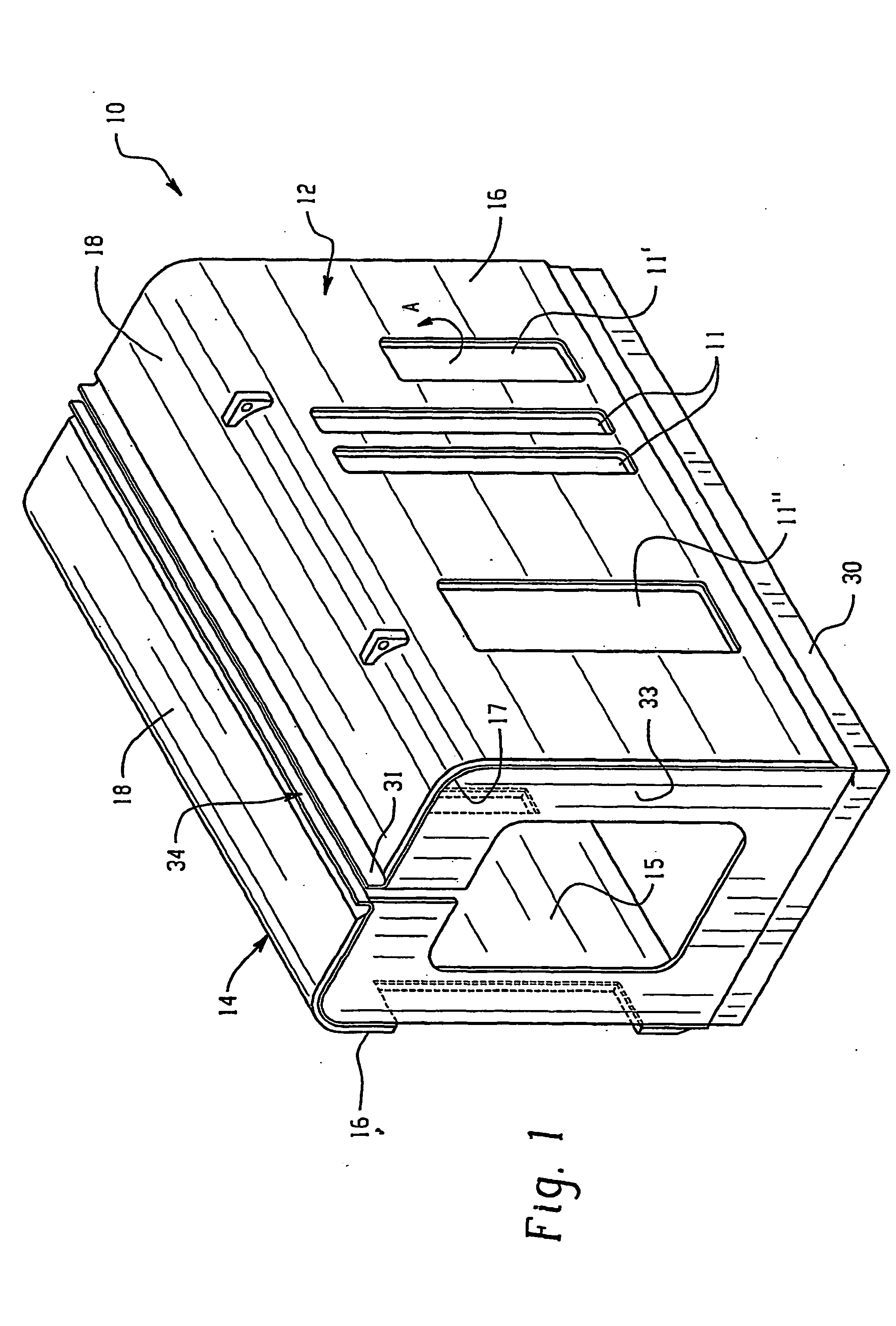

[0012] The invention herein provides for an improved powder coating spray booth. In one embodiment, which is well-suited for

retrofitting existing powder coating spray booths, the invention herein comprises a pair of opposed canopy halves that each have a sidewall and a ceiling portion that can be connected to each other through a

radius. This

radius serves to reduce color change times and functions as a torsional support element for the wall and ceiling surfaces. Each canopy half is a seamless, composite, unitary structure that can connect with an existing booth floor and with the existing booth

vestibule and / or aperture end or ends, and can be separated at the top providing for a narrow overhead conveyor slot opening typical in electrostatic powder coating spray booths. The canopy halves are each self-supporting, which means they can be assembled together with an existing floor and

vestibule end or ends and no external frame is required to support the powder coating spray booth of the present invention. By removing the external frame typical of all known powder coating spray booths and constructing the inventive booth canopies from nonconductive materials, the improved booth can be assembled much quicker and is more nonconductive to oversprayed electrostatic powder particles. Thus, less oversprayed

particle coating material adheres to the ceiling and walls of the inventive booth. Of course, it can be appreciated by those skilled in the art that this improved embodiment of the invention can also work equally well with a new floor or vestibule end.

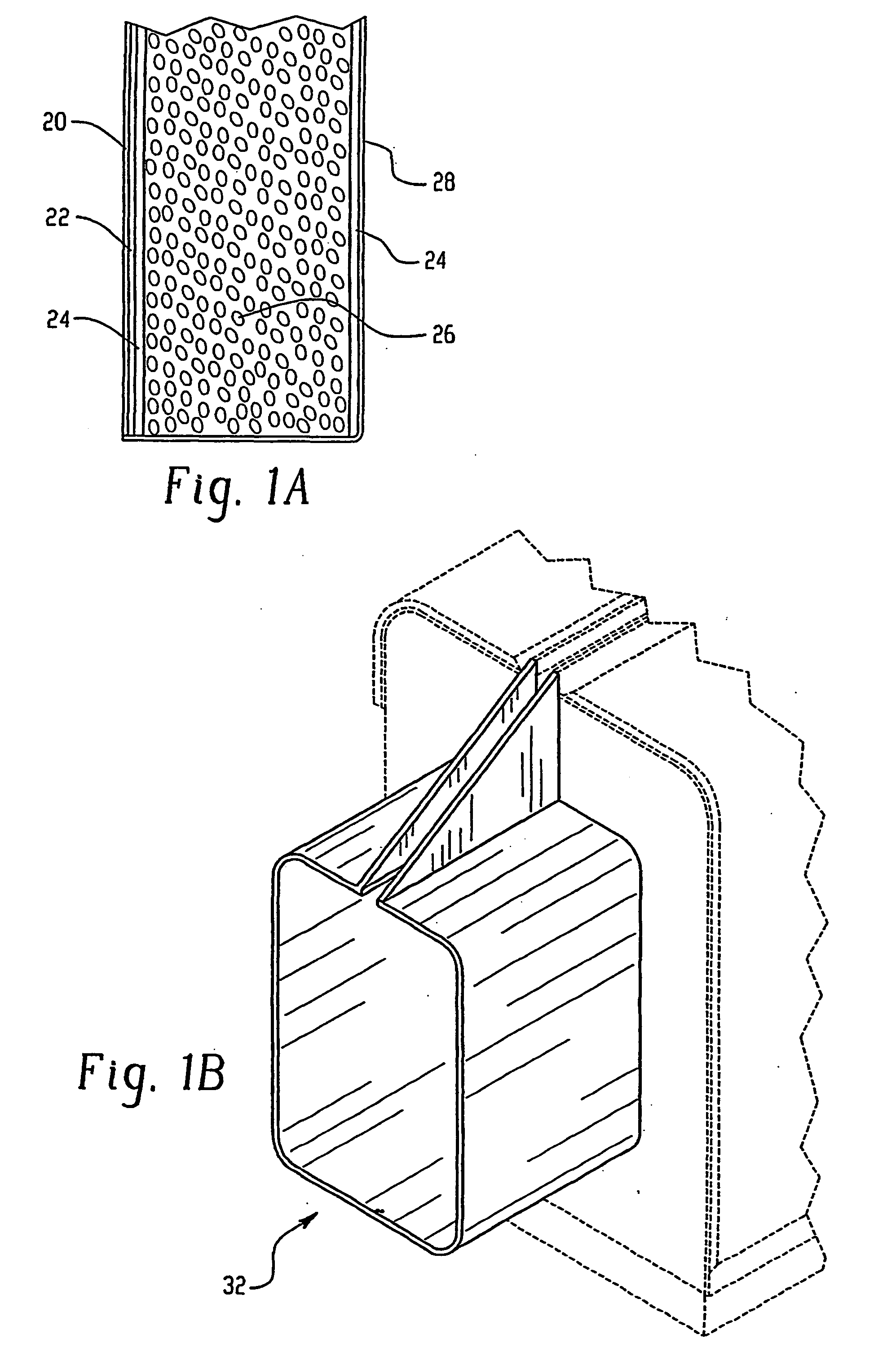

[0013] The canopy halves of the present invention are made from a number of non-

conductive materials that are loaded onto a set-up tool having a

smooth surface that has been prepared with a

release agent. All the materials can be non-metallic. Typical non-conductive

layers can include a first, optional, sprayed on layer of gel-coat, which is an unreinforced resin layer that is allowed to set or cure. This first layer of the booth canopy halves serves as the booth interior surface. It may be pigmented, such as with white

pigment, for aesthetics and functional reasons, such as to give a clean smooth appearance and to help the worker identify the location of oversprayed powder coating material within the spray booth during booth cleaning for a color change. The specific resin material chosen is non-conductive,

ultraviolet light stable and impervious to

moisture adsorption, even over time. This layer can be followed by an optional layer of chopped strand mat which is a random orientation

glass fiber product. Also included are three necessary

layers including a core having a suitable thickness to give the canopy halves

structural rigidity and a first and a second layer of knitted

glass fabric sandwiching the core for strength. One or more handling tabs can be placed within the lay-up of the composite canopy halves, such as at perimeter edges or at the outer

radius between the ceiling and wall portions, to assist with handling the composite canopy halves during lifting the newly formed canopy half from the tool, secondary operations in finishing the canopy half, storage, transportation and booth assembly at a production site. These handling tabs can be simple nonconductive lugs, such as of similar

composite construction and already cured before placement in the lay-up.

[0015] The cured canopy halves can be lifted off the set-up tool, trimmed and have their access and other operational openings

cut. A final exterior layer of

gelcoat, again a pigmented or unpigmented unreinforced resin layer can be applied for aesthetics and to further inhibit

moisture adsorption over time and during shipping to the production site. Alternatively, an

epoxy-based barrier coat can be applied in place of the

gelcoat for the same purposes. Either coating layer on the part exterior serves to effectively seal the part from the elements during shipping and fills in any pinholes that may be present on the exterior or trimmed surfaces of the composite canopy half.

[0016] In accordance with another aspect of the invention, each canopy half of the inventive spray booth can be essentially mirror images of each other and produced with the same tooling. As such, they can be shipped to the production site in a nested configuration, minimizing shipping space. In addition, each canopy half can have one or more access and other operational openings which are positioned in the canopy half during construction by measured placement of the core material, essentially removing the core material where an access opening is desired. A

flange around the perimeters of the canopy halves can be provided by tapering the core layer to zero thickness and creating a

flange from the remaining

layers, as described above. These perimeter flanges can be used for connecting the floor and the booth ends, which can be narrowed vestibules that are known to help retain oversprayed powder coating material inside the spray booth. Alternatively, one or both of the vestibule ends can be replaced with aperture bulkheads that establish a part opening in the booth end or ends.

[0021] In another inventive powder coating booth embodiment, a nonconductive, self-supporting, spray booth canopy is provided that includes a pair of composite canopy halves each having a wall and ceiling portion and at least one integral vestibule end half, or aperture bulkhead half. In addition, each canopy half can have an integral floor portion with the assembled canopy halves requiring a suitable utility base section for connecting thereto. The integral floor portions of either half, or both halves may be sloped to facilitate oversprayed powder coating material collection in one or more collection troughs located below the booth floor. Otherwise, a floor is provided to connect with the canopy halves at perimeter wall and vestibule or aperture bulked edges. An overhead conveyor slot opening for passing parts through the booth can be provided. The canopy halves are nonconductive for mininizing the adherence of electrostatically charged oversprayed powder coating material to the booth interior surfaces.

Login to View More

Login to View More