Electro-optic assemblies and materials for use therein

a technology of optical assemblies and materials, applied in the direction of instruments, film/foil adhesives, non-macromolecular adhesive additives, etc., can solve the problems of preventing their widespread use, imposing stringent requirements on lamination adhesives, and inadequate service life of these displays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

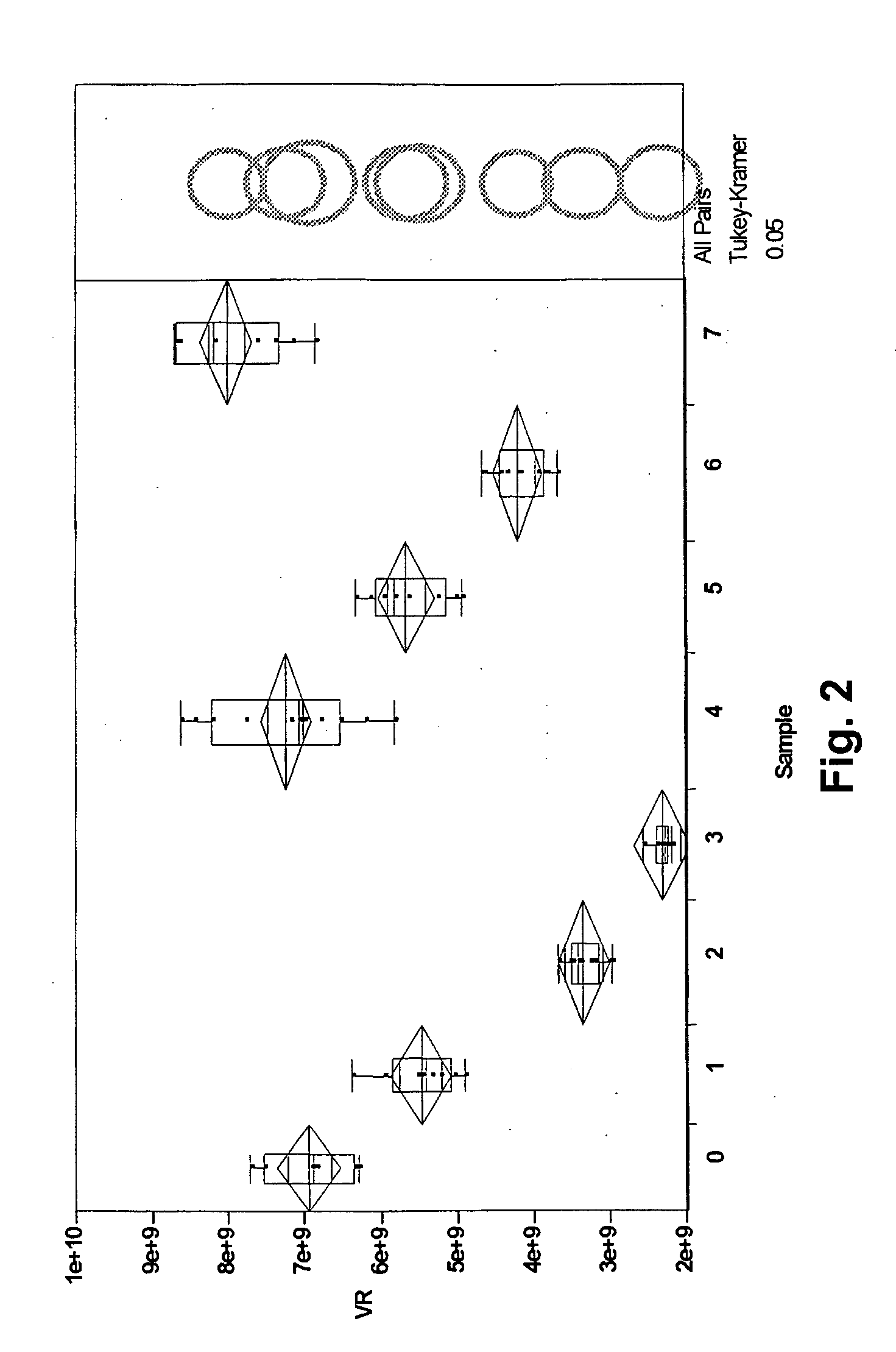

example 1

[0075] A base adhesive material was prepared by blending NeoRez (Registered Trade Mark) 9630 and NeoRez 9330, two polyurethane dispersions available commercially from NeoResins, Inc., 730 Main Street, Wilmington Mass. 01887. This material was divided into eight samples of approximately 50 g each, each sample containing 40 percent by weight of solids, and varying amounts of potassium acetate, tetrabutylammonium chloride, or poly(acrylic acid) aqueous solution were added as indicated in the Table below; a control sample was also provided with no additives.

TABLESampleWeight ofMass (g) ofNo.sample (g)Additiveadditive050.12N / A0150.00Bu4NCl0.012250.06Bu4NCl0.051350.30Bu4NCl0.099450.10KOAc0.007549.99KOAc0.040650.00KOAc0.082750.00PAA, sodium salt0.156(40% wt aq.)

[0076] Each of the samples was mixed for a period of 7 to 10 days to ensure a thoroughly homogeneous product and to re-disperse any gel-like solids, which formed as a result of adding the additive as a solid to the sample. At the ...

example 2

[0079] This Example illustrates the effect of tetrabutylammonium hexafluorophosphate (NBU4PF6) in lowering the volume resistivity of an adhesive material as described in the aforementioned copending application Ser. No. 10 / 715,916.

[0080] Stock solutions of NBu4PF6 containing from 10 to 200 mg of the salt per gram of solution were prepared, and added to various aliquots of a polyurethane dispersion to produce the desired levels of the salt ranging from 10−7 to 10−4 moles of the salt per gram of adhesive solids (approximately 100 to 100,000 ppm of the salt on a weight / weight adhesive solids basis). The resultant salt solution / dispersion mixtures were mixed on a roller mill for at least three hours to ensure complete mixing.

[0081] The salt-containing dispersions thus prepared were coated in the same way as in Example 1 above and dried at 60° C. in air for at least 10 minutes to produce dried adhesive layers having thicknesses from 12 to 20 μm. The resultant adhesive layers were then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| resistivities | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com