Single reactor, multi-pressure chemical vapor deposition for semiconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

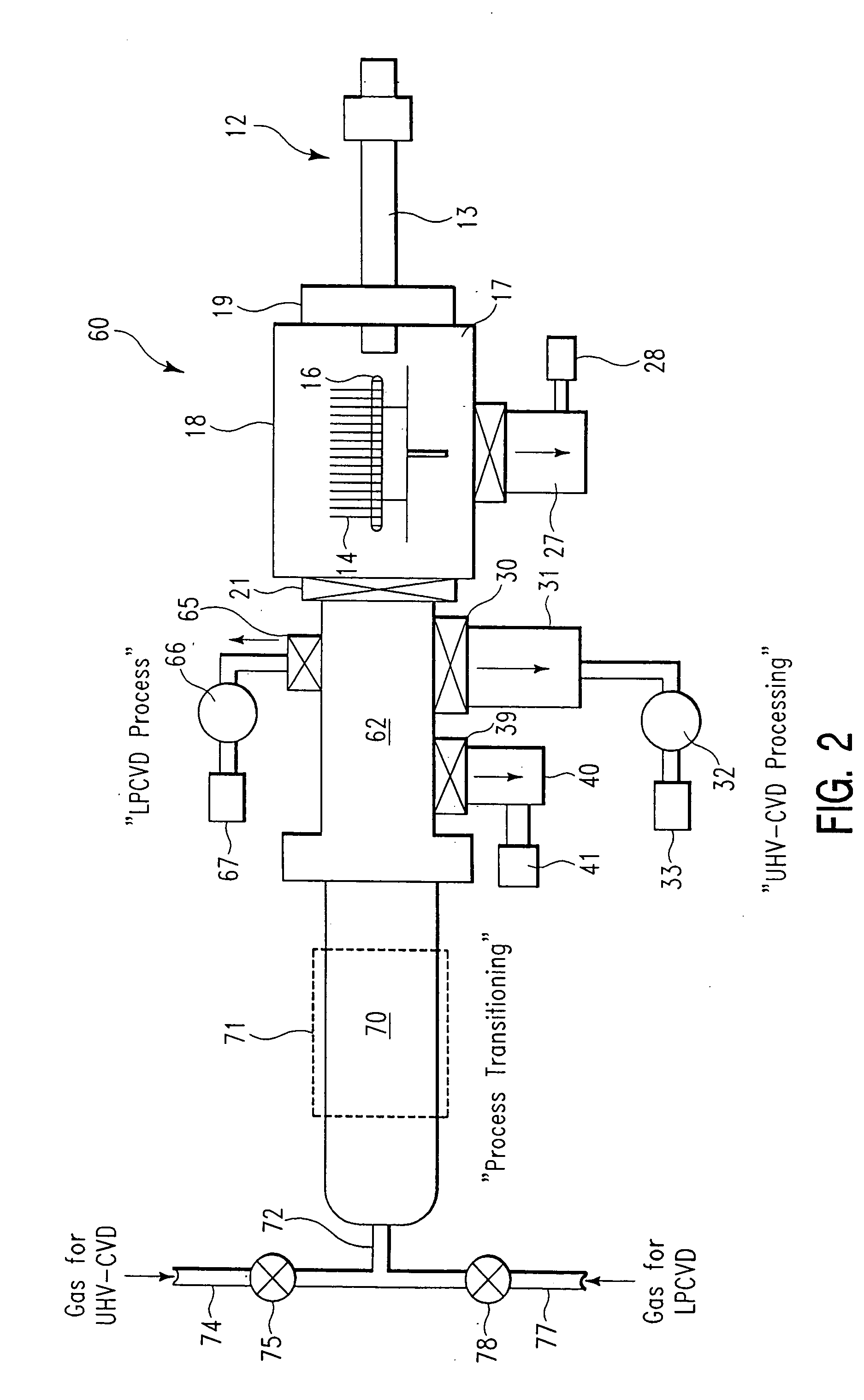

[0036] A method of operation for the AICVD system 60 shown in FIG. 2 would provide the following processes to fabricate any high performance Si and / or SiGe device structure, such as shown in FIG. 3.

[0037] Start with wafers 14 having a Si substrate 83 outside of the AICVD 60 after cleaning the wafers using a standard Huang or RCA cleaning process well known in the art.

[0038] Load the cleaned wafers 14, which may be supported on the boat 16, into the load lock chamber 18, and then transfer the wafers on boat 16 into the quartz tube reactor 70 after opening gate valve 21 and operating roots blower 66 and mechanical pump 67 to provide an LPCVD pressure environment.

[0039] Under a blanket of H2, pre-bake wafers 14 in the temperature range from 800° C. to 950° C. for 5 to 30 minutes at a process pressure of 100-500 mtorr to remove native oxides and prepare silicon surface 84.

[0040] Activate the Dichlorosilane (DCS) source, cease H2 flow, and grow the Si epitaxial pre-layer 85 to a desi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com