Non-curling reinforced composite membranes with differing opposed faces, methods for producing and their use in varied applications

a technology of opposed face and reinforced composite membrane, which is applied in the direction of weaving, transportation and packaging, and other domestic objects, can solve the problems of limiting the usefulness of the material, affecting the performance of the material, so as to achieve the effect of optimizing performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

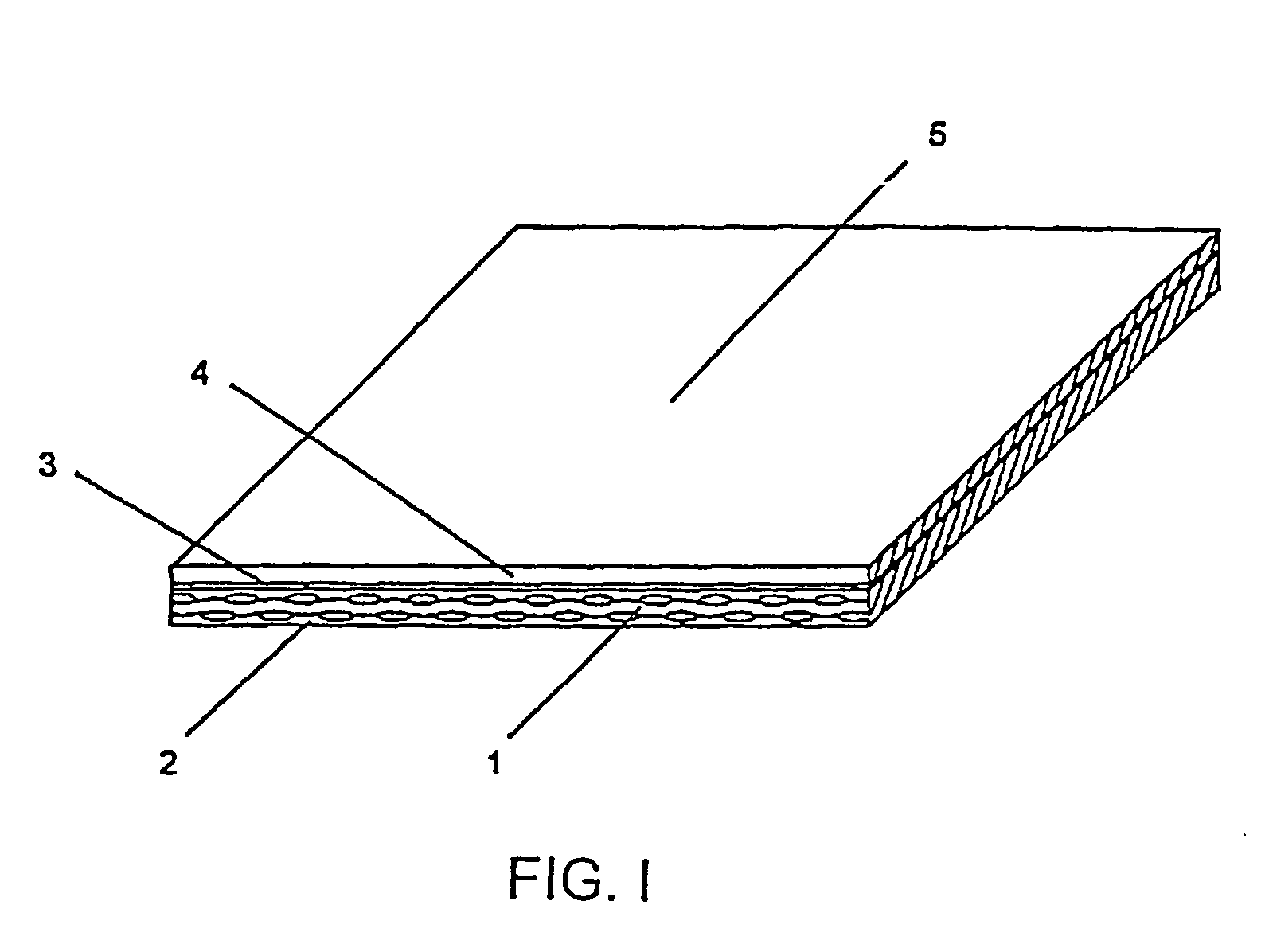

Image

Examples

example 1

[0017] One face of a roll of commercially available PTFE / glass fabric (Chemfab Chemglas® Basic 5), containing style 2116 glass fabric as a reinforcement and comprised of about 50 percent by weight PTFE resin and 50 percent by weight glass, is rendered bondable by applying a mixture of colloidal silica dispersion (DuPont Ludox® 40), PFA fluoropolymer resin solution (Dupont TE-9946), surfactants, stabilizers, and water; wiping off the excess; drying; baking; and fusing. The fabric weighs about 5.4 ounces per square yard (osy) and is about 0.005 inches thick.

[0018] Using conventional PTFE tower-coating equipment, a coating of an LSR formulation composed of 50 parts by weight each of Wacker Silicones Elastosil® LR6289A and LR6289B and about 12 parts by weight of a red iron oxide masterbatch containing about 35 percent iron oxide and about 65 percent vinyl terminated silicone polymer, is applied to the bondable face of the Chemglas Basic 5. The tower is operated to provide conditions of...

example 2

[0020] One face of another roll of the PTFE / glass fabric used in the above example is rendered bondable by treatment with a solution of sodium, naphthalene, and glycol ether. It is coated using the procedure described in Example 1, yielding a composite with physical properties almost identical to those of Example 1.

example 3

[0021] One face of a length of Chemltas 64-40916, a Chemfab product comprised of Style number 64 glass fabric saturated / coated with 40 percent by weight PTFE, is rendered bondable by application of the colloidal silica formulation as described in Example 1 and coated with 8 osy. of silicone rubber. The resulting product is fabricated into a belt 50 meters long and 1.5 meters wide. It is substituted for a conventional glass-reinforced silicone rubber belt used as a conveyor and release surface in the assembly of plastic wine bags by heat sealing. The silicone release surface of the conventional belt performs to the user's satisfaction, but the construction is difficult to drive on the user's equipment due to excessive frictional force generated when the rubber non-working face of the belt, i.e., the face that does not contact the product, slides over stationary components of the machine. The PTFE non-working face of the example belt generates minimal frictional force against the mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com