Developing solution for lithographic printing plate precursor and method for making lithographic printing plate

a technology of lithographic printing plate and precursor, which is applied in the direction of diazo-type processes, photomechanical devices, instruments, etc., can solve the problems of difficult to make highly excessive development or defective development, and small difference between light-exposure and un-exposure, etc., to achieve favorable image forming performance, high sharp and clear images, and certain performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

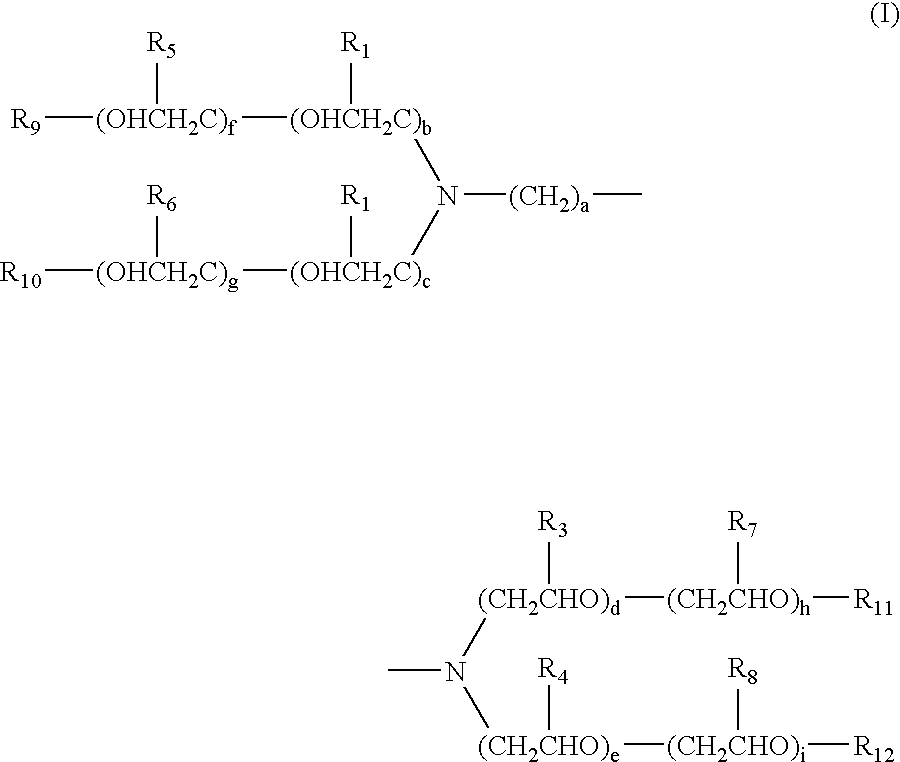

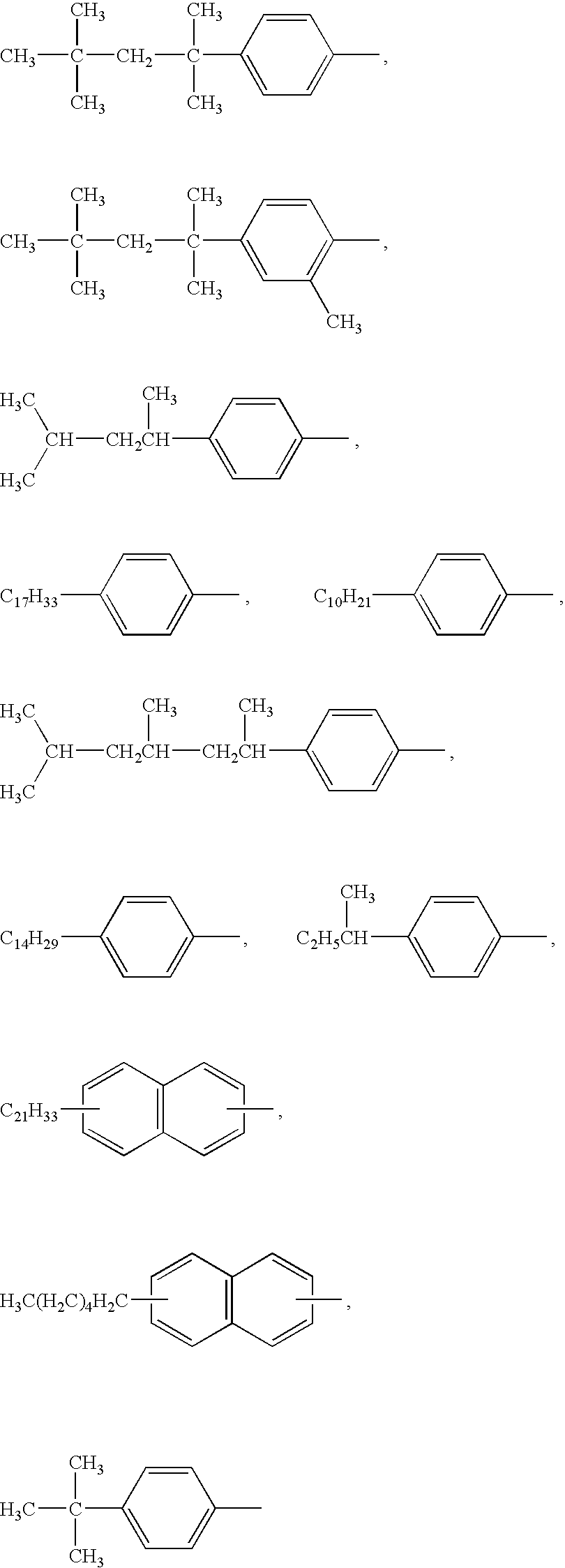

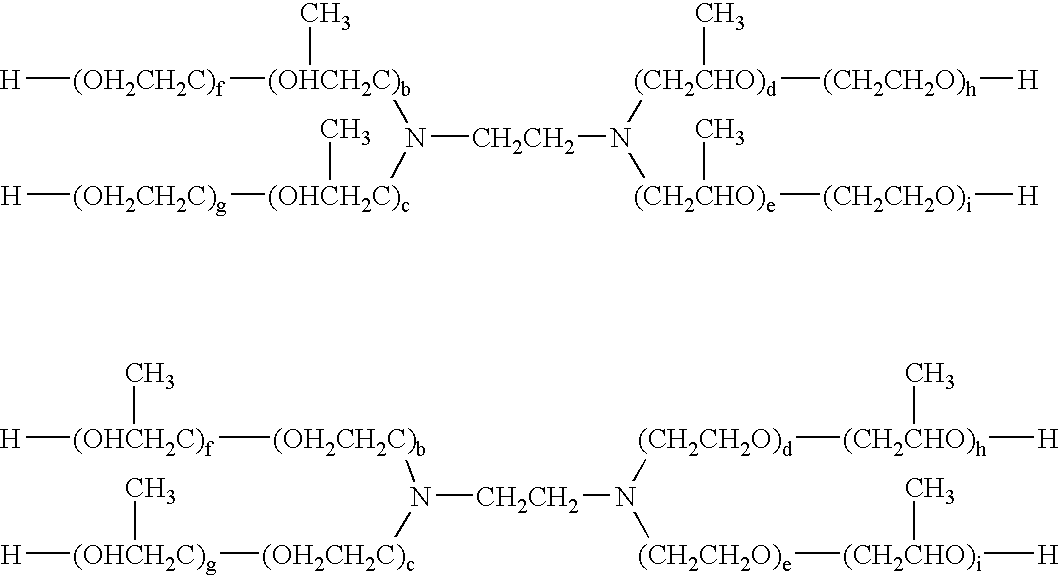

Method used

Image

Examples

examples

[0275] The present invention will hereinafter be explained in more detail with reference to the following non-limitative working Examples.

(Preparation of Heat-Sensitive PS plate)

[Preparation of Aluminum Substrate]

[0276] An aluminum substrate having a hydrophilic surface was prepared as described below. An aluminum plate of 0.3 mm thickness (grade 1050) was washed with trichloroethylene to be degreased, and surface-grained with a nylon brush and an aqueous suspension of 400 mesh pumice stone, and then sufficiently washed with water. The aluminum plate was then subjected to an immersed-electrolytic etching in a 25% aqueous solution of sodium hydroxide at 45° C. for 9 seconds, washed with water, and further immersed in a 20% aqueous solution of nitric acid for 20 seconds, and washed with water. The etching amount of grained surface was about 3 g / m2. Then it was anodized in a 7% aqueous solution of sulfuric acid at a DC current density of 15 A / dm2 so that the thickness of the result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com