Method, an arrangement, and a computer readable storage device for controlling homogeneous charge compression ignition combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

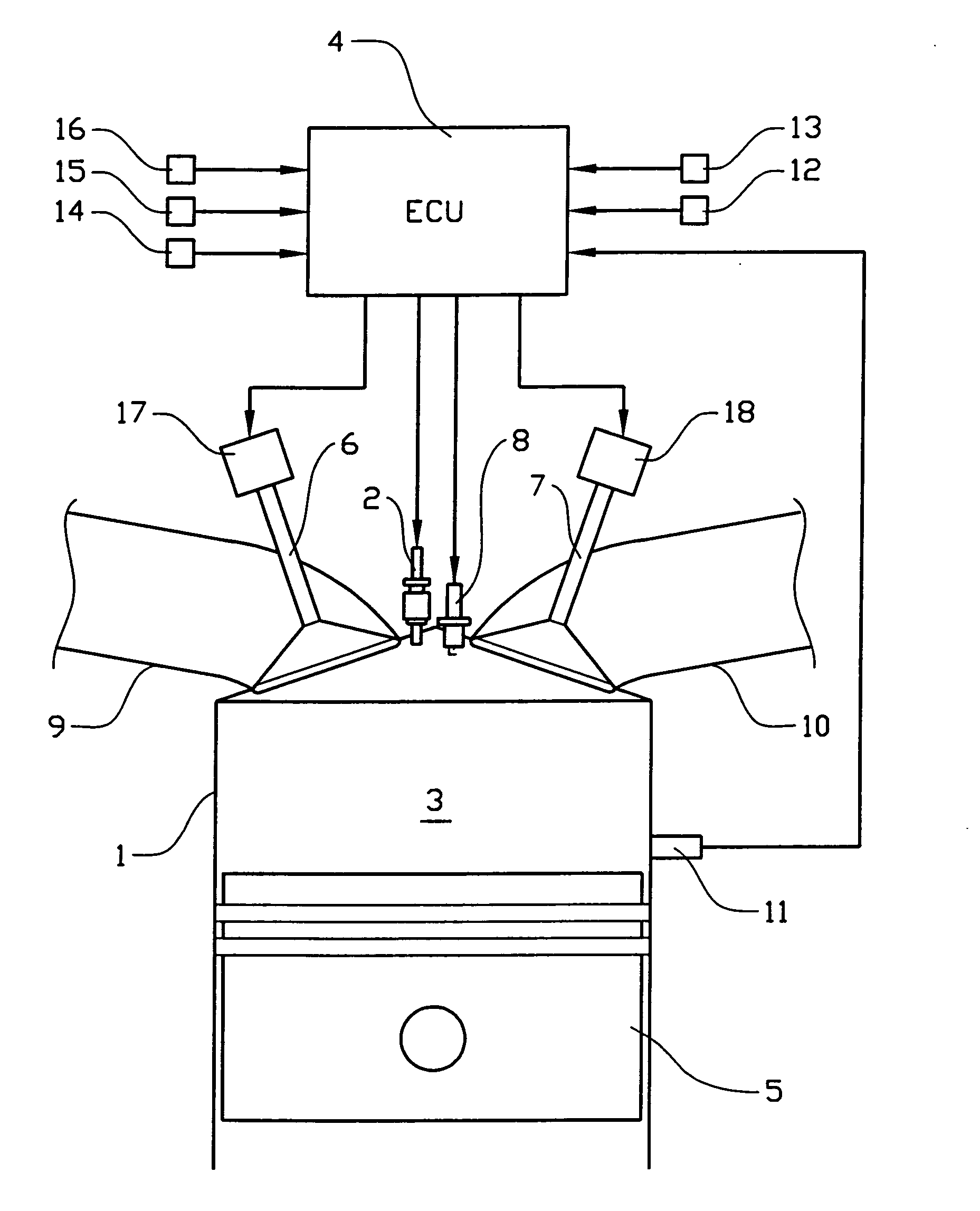

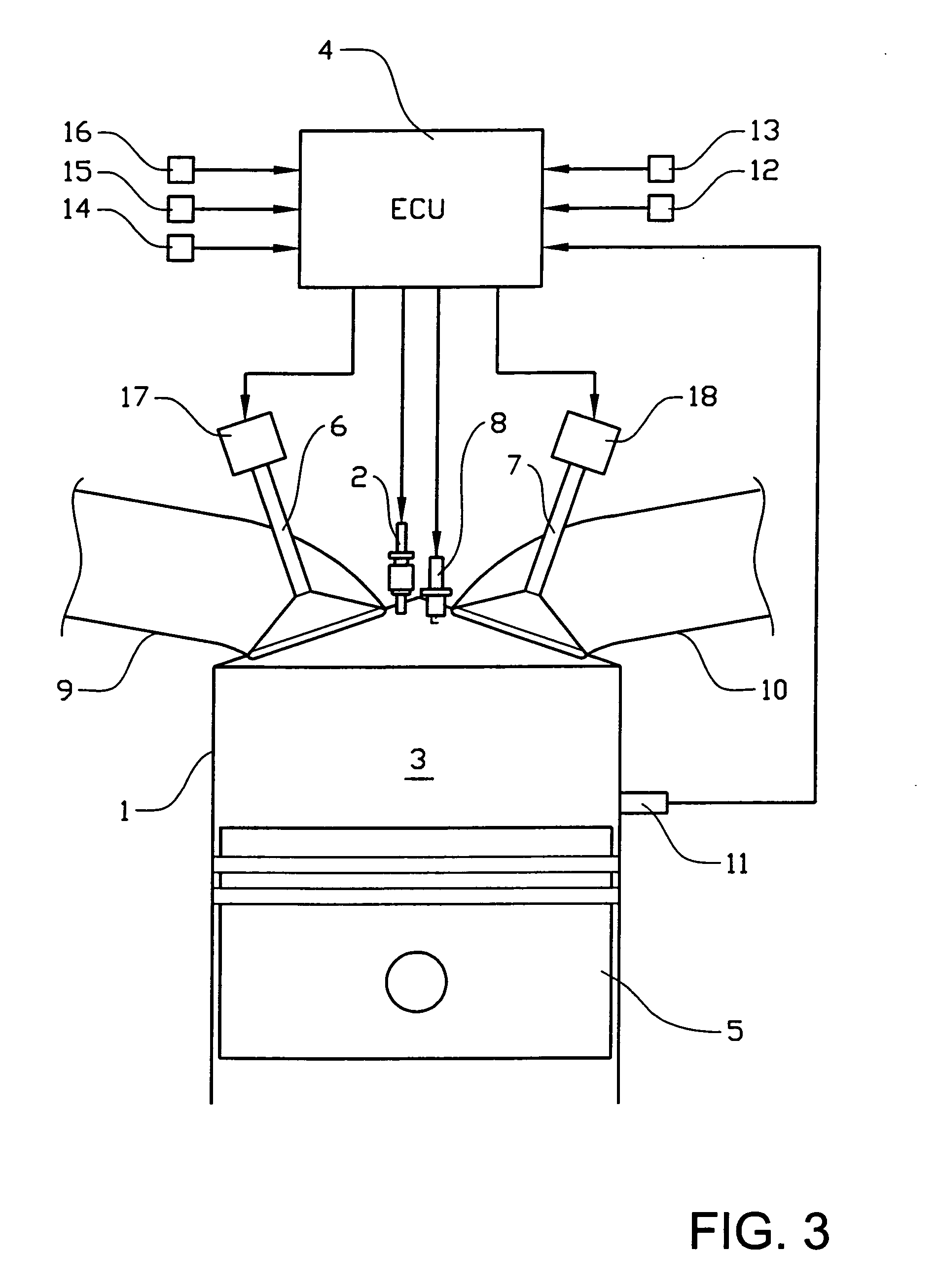

[0036]FIG. 3 shows a schematic illustration of an internal combustion engine according to the invention. The engine is provided with at least one cylinder 1 and comprises a fuel injector 2, through which fuel is injected into a combustion chamber 3, for each cylinder. A fuel injection control unit 4 controls fuel injection quantity per combustion cycle injected through each fuel injector. A piston 5 in the engine cylinder has a compression action that causes a mixture of air and fuel within the combustion chamber to be ignited during HCCI-mode. The cylinder is provided with at least one inlet valve 6 for admitting gas which includes fresh air into the cylinder and at least one exhaust valve 7 for exhausting combusted gases from the cylinder. Air is supplied through an intake conduit 9 connected to an intake manifold, while exhaust gas is exhausted through an exhaust conduit 10. During SI-mode, the ignition of the fuel / air mixture is ignited by a spark plug 8.

[0037] The control unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com