Hydrodynamic bearing device and spindle motor using the same

a technology of hydrodynamic bearing and spindle motor, which is applied in the direction of sliding contact bearings, mechanical instruments, mechanical equipment, etc., can solve the problems of insufficient reliability of the device, shortened service life of the device, and evaporation of lubricant, etc., to achieve excellent heat resistance and low-temperature fluidity, high reliability, and high performance of the hydrodynamic bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

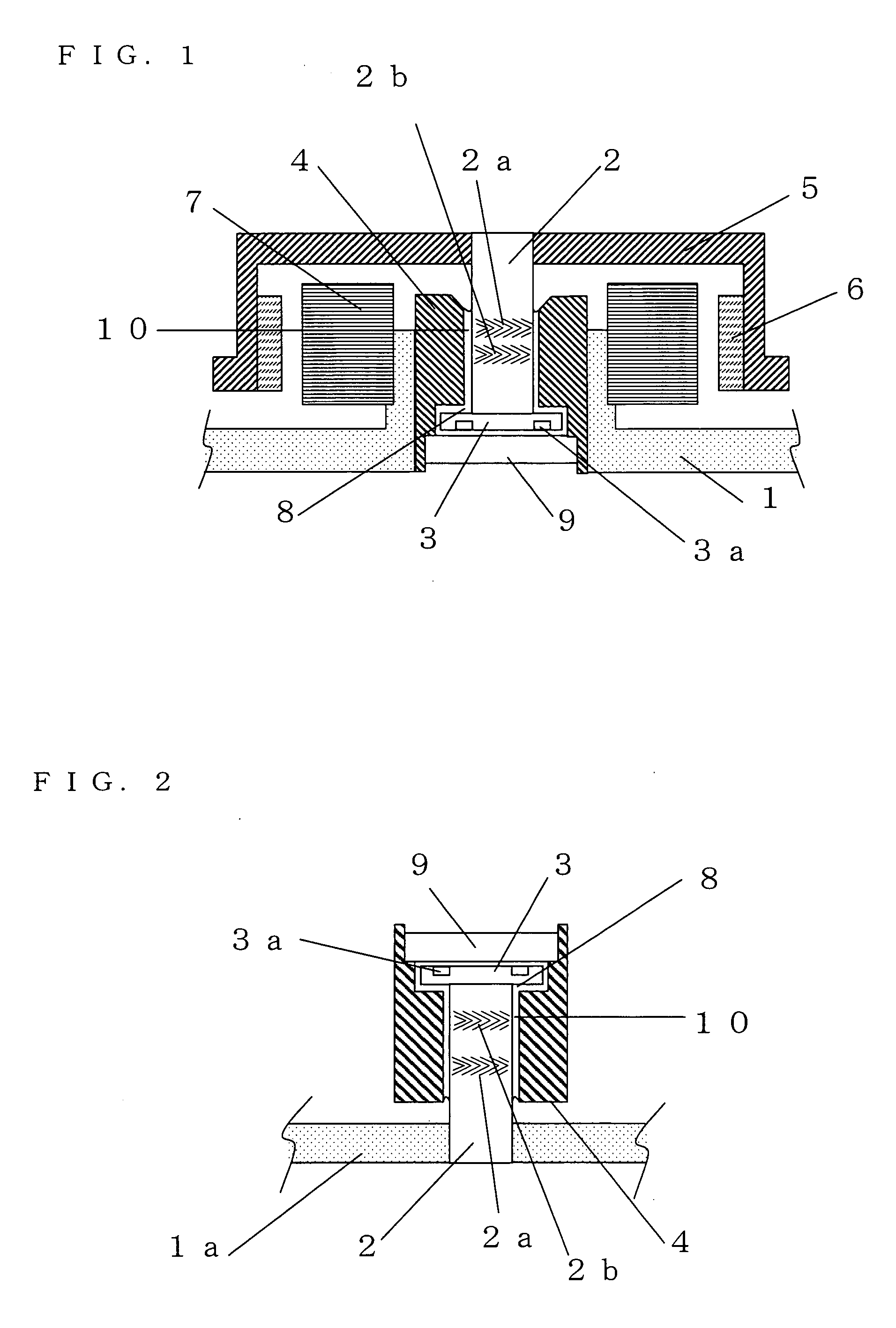

[0048] Embodiment 1 of the present invention will be described with reference to FIG. 2.

[0049]FIG. 2 is a schematic cross-sectional view showing a shaft-fixed type hydrodynamic bearing device. In FIG. 2, a base 1a, a shaft 2, radial dynamic pressure generation grooves 2a and 2b, a thrust flange 3, a thrust dynamic pressure generation groove 3a, a sleeve 4, a lubricant 8, a thrust plate 9 and a radial clearance 10 are shown.

[0050] The thrust flange 3 is fixed at one end of the shaft 2, on the outer peripheral surface of which the radial dynamic pressure generation grooves 2a and 2b being herringbone-shaped are formed, whereby a shaft section is formed. The other end of the shaft 2 is press-fitted in and fixed to the base 1a. The shaft section is inserted into the bearing hole of the sleeve 4, and the thrust plate 9 is installed in the sleeve 4 so as to be opposed to the thrust flange 3 and to block one side of the bearing hole. In addition, the thrust dynamic pressure generation gr...

embodiment 2

[0068] Embodiment 2 of the present invention will be described with reference to FIG. 2 again. This embodiment is similar to Embodiment 1 except for the difference in the ingredients of the lubricant 8.

[0069] The lubricant 8 differs from the lubricant 8 in accordance with Embodiment 1 in that esters obtained from a divalent alcohol having 4 to 8 carbon atoms and having no alkyl side chain at the 3 position, a saturated dibasic acid having 6 to 10 carbon atoms and a saturated monovalent fatty acid having 5 to 13 carbon atoms are used instead of a diester obtained from a divalent alcohol having 4 to 8 carbon atoms and having no alkyl side chain at the 3 position and a saturated monovalent fatty acid having 9 to 13 carbon atoms. In other respects, the lubricant 8 is similar to the lubricant 8 in accordance with Embodiment 1.

[0070] Esters obtained from a divalent alcohol having 4 to 8 carbon atoms and having no alkyl side chain at the β position, a saturated dibasic acid having 6 to 1...

embodiment 3

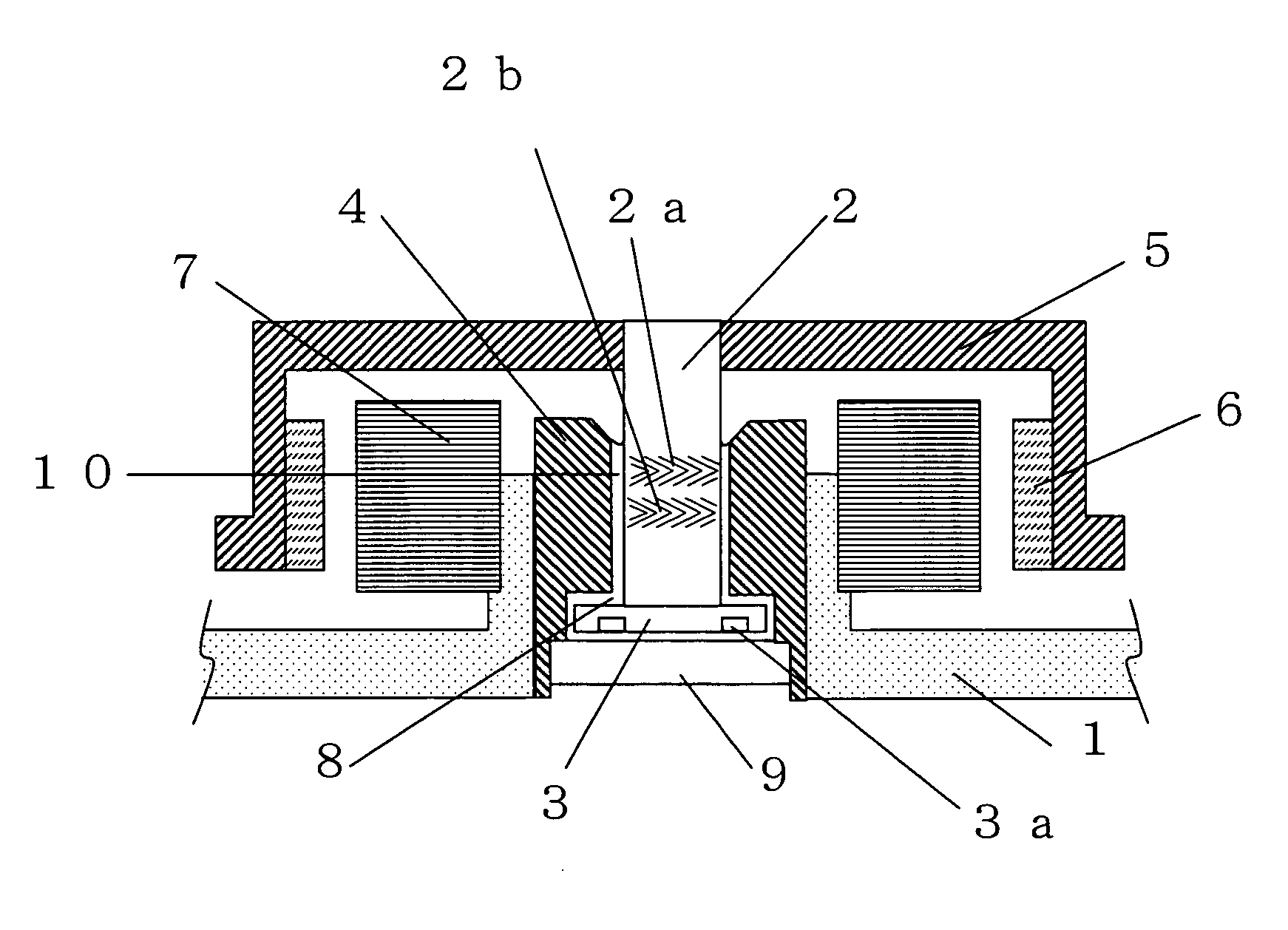

[0077] Embodiment 3 of the present invention will be described with reference to FIG. 1.

[0078]FIG. 1 is a cross-sectional view showing a spindle motor having a shaft-rotation type hydrodynamic bearing device in accordance with Embodiment 3. The hydrodynamic bearing device in accordance with this embodiment differs from the hydrodynamic bearing device shown in FIG. 2 in that the hydrodynamic bearing device is changed from a shaft-fixed type to a shaft-rotation type, that a base 1 is provided instead of the base 1a, and that a hub 5, a rotor magnet 6 and a stator coil 7 are provided. In other respects, this embodiment is similar to Embodiment 1; components having similar or equivalent configurations are designated by the same numerals, and their detailed descriptions are omitted.

[0079] A thrust flange 3 is fixed at one end of a shaft 2, on the outer peripheral surface of which herringbone-shaped radial dynamic pressure generation grooves 2a and 2b are formed, and the hub 5, on which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com