Pharmaceutical compositions

a composition and composition technology, applied in the field of pharmaceutical compositions for oral administration, can solve the problems of unable to improve intestinal drug absorption, lose its potential bioadhesive and absorption enhancing properties, and the composition that meets these requirements is a significant challenge, so as to achieve the effect of enhancing the absorption of the drug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

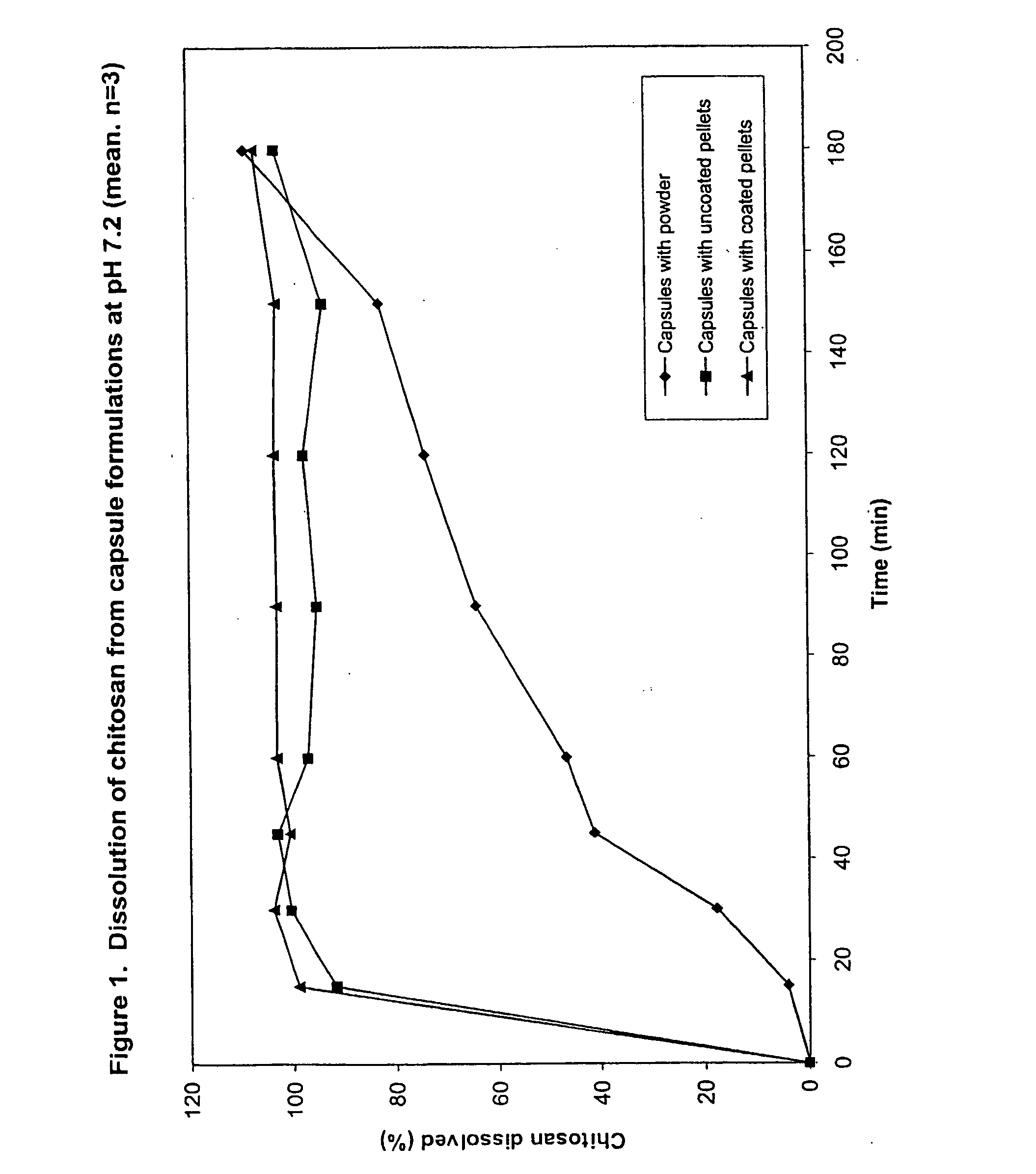

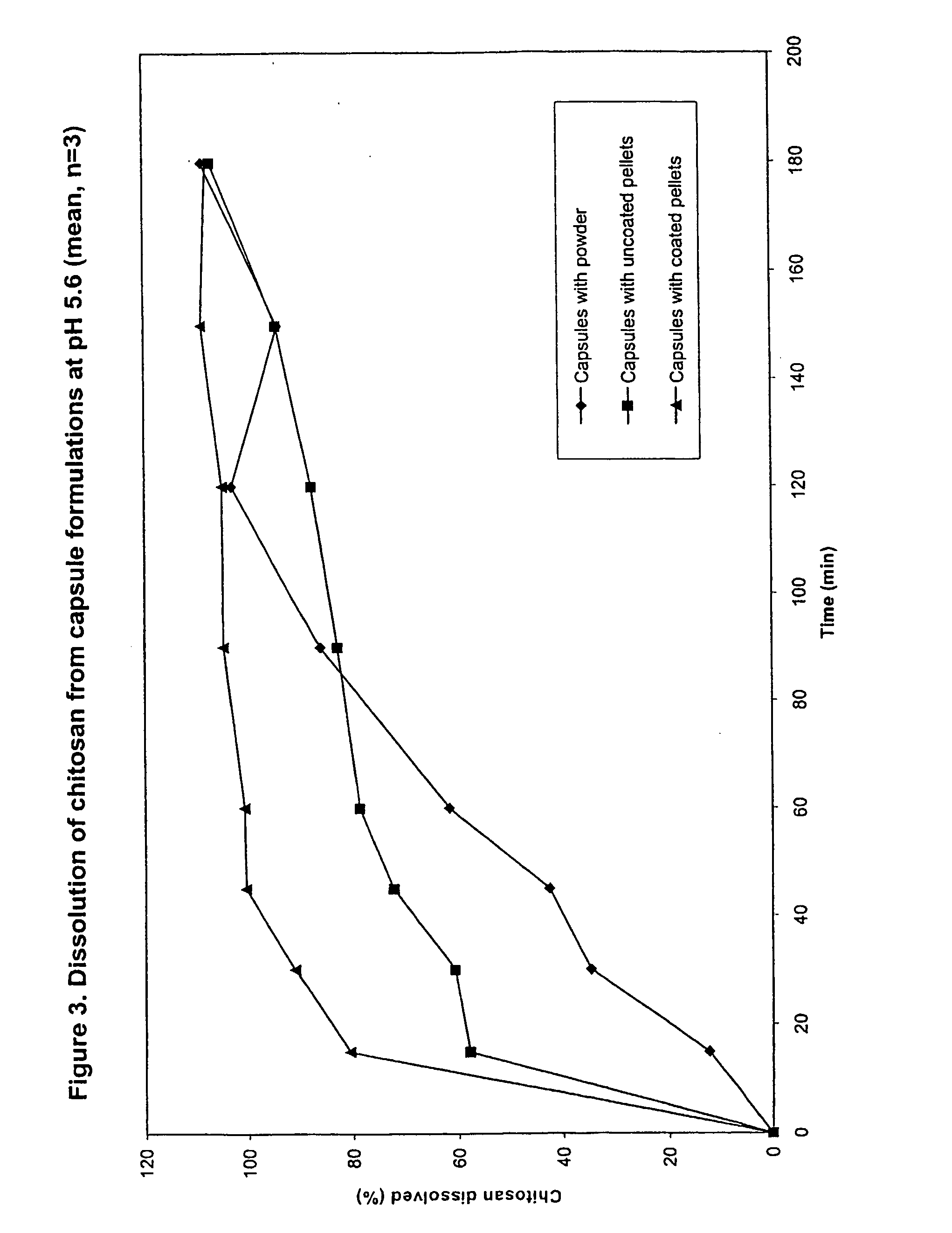

Preparation and Dissolution Testing of Chitosan Tablets

[0075] A powder blend was prepared by mixing together 20 grams of chitosan (ChitoClear®, Primex, Haugesund, Norway) and 80 grams of mannitol (Pearlitol SD200, Roquette, Lestrem, France). The chitosan had a degree of deacetylation of 93% and an approximate average molecular weight of 200,000 Da. The powder blend was compressed using a Manesty F3 tablet press (from Manesty, Liverpool, UK) fitted with 9 mm diameter circular tooling to produce tablets.

[0076] The dissolution of the tablets was measured in pH 7.4 HEPES buffer at 37° C. using United States Pharmacopeia Method II (USP26 / NF21, United States Pharmacopeia Convention, Rockville, Md., USA, 2002) with paddles at 100 rpm. 250 ml of buffer was used in each dissolution beaker.

[0077] Samples of dissolution medium were collected at periodic intervals up to 240 minutes, filtered (0.45 μm) and measured for chitosan content using a ninhydrin assay.

[0078] To perform the chitosan a...

example 2

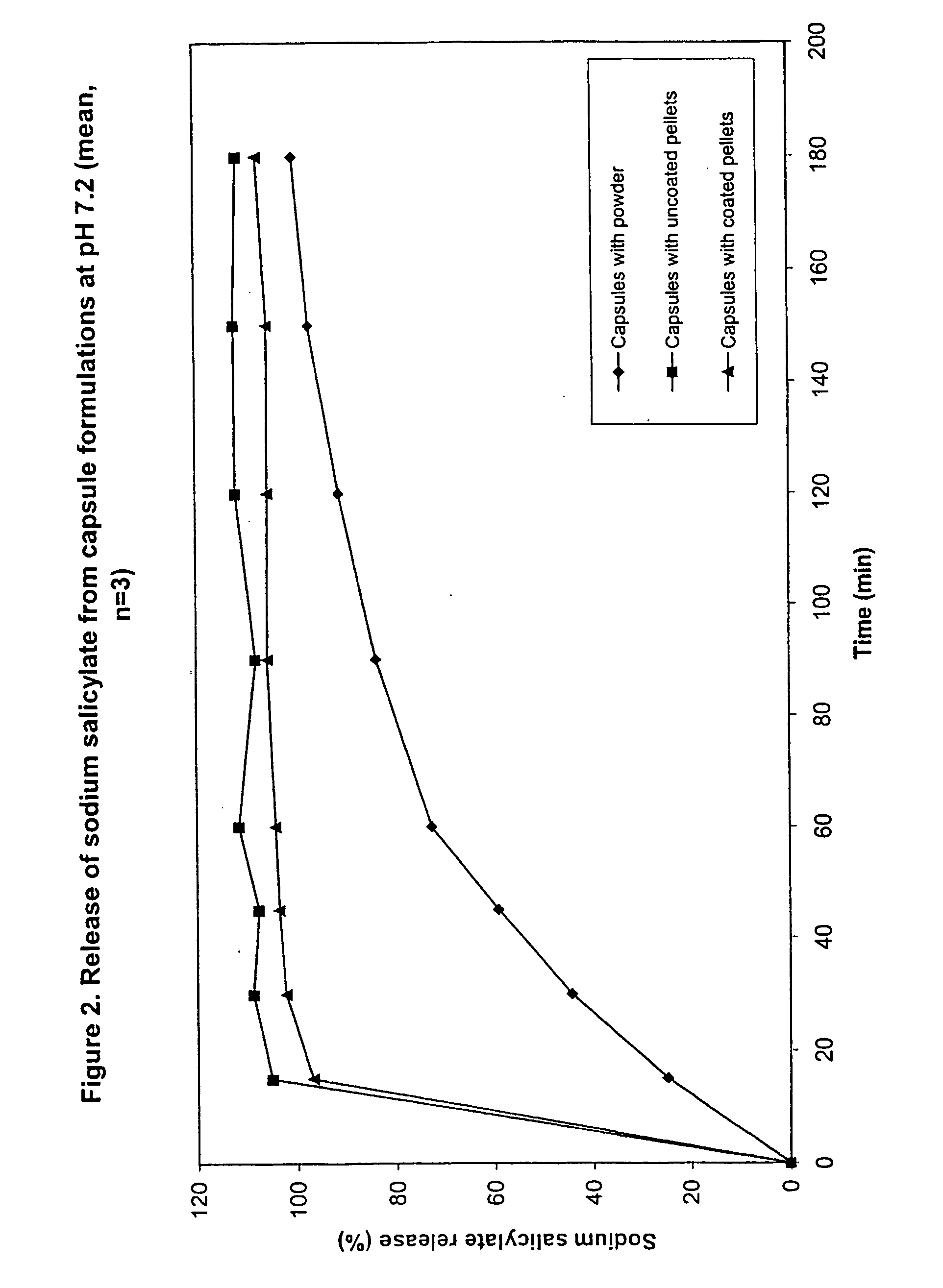

Preparation of Succinic Acid / Sodium Salicylate Pellets

[0080] 220 grams of microcrystalline cellulose (Avicel PH101, FMC, Philadelphia, USA), 200 grams of succinic acid (Sigma) and 20 grams of sodium salicylate (Fluka, Buchs, Switzerland) were added to the bowl of a Kenwood food mixer. The mixture was blended for 3 minutes at 60 rpm. Water was added gradually while mixing to granulate the blend. When the granulate was deemed to have reached a consistency suitable for extrusion (230 ml water added), addition was stopped and mixing continued for a further 10 minutes. The material was then extruded using a Caleva Model 10 extruder (Caleva, Sturminster Newton, Dorest, UK) at 15 rpm. The diameter of the holes on the extruder was 1 mm. The extrudate was then spheronised in approximately 45 gram batches using a Caleva Model 120 spheroniser (Caleva, Sturminster Newton, Dorest, UK) for 10 minutes at setting 75 (2250 rpm). The pellets were dried overnight in an oven at 50° C. The final yield ...

example 3

Preparation of Coated Succinic Acid / Sodium Salicylate Pellets

[0081] 150 ml of water was heated to approximately 80° C. 10 grams of hydroxypropyl methylcellulose (Methocel E5 LV, Colorcon, Orpington, UK) was dispersed into the hot water. The dispersion was cooled in an ice bath while stirring until a clear solution had formed. The solution was made up to 200 ml with water.

[0082] The pellets produced in Example 2 were sieved and the fraction between 0.71 and 1.00 mm collected (251 grams). 200 grams of these pellets were placed into the coating chamber of an Aeromatic STREA-1 fluidised bed coater (bottom spray) (Niro Aeromatic, Bubendorf, Switzerland). The Methocel solution was applied to the pellets at a coating temperature of 60° C. and application rate of 1.5 grams / minute. 175 ml of coating solution was applied giving a theoretical HPMC content in the final pellets of 4.4% w / w.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com