Method for preparing improved soybean products

a technology of soybeans and products, applied in the field of soybean preparation, can solve the problems of undesirable off-flavors, significantly lower yields of oligosaccharides, and undesirable greyish color of soybeans, and achieve the effect of improving the overall nutritional profile of the treated soybeans, low cost, and simplified method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

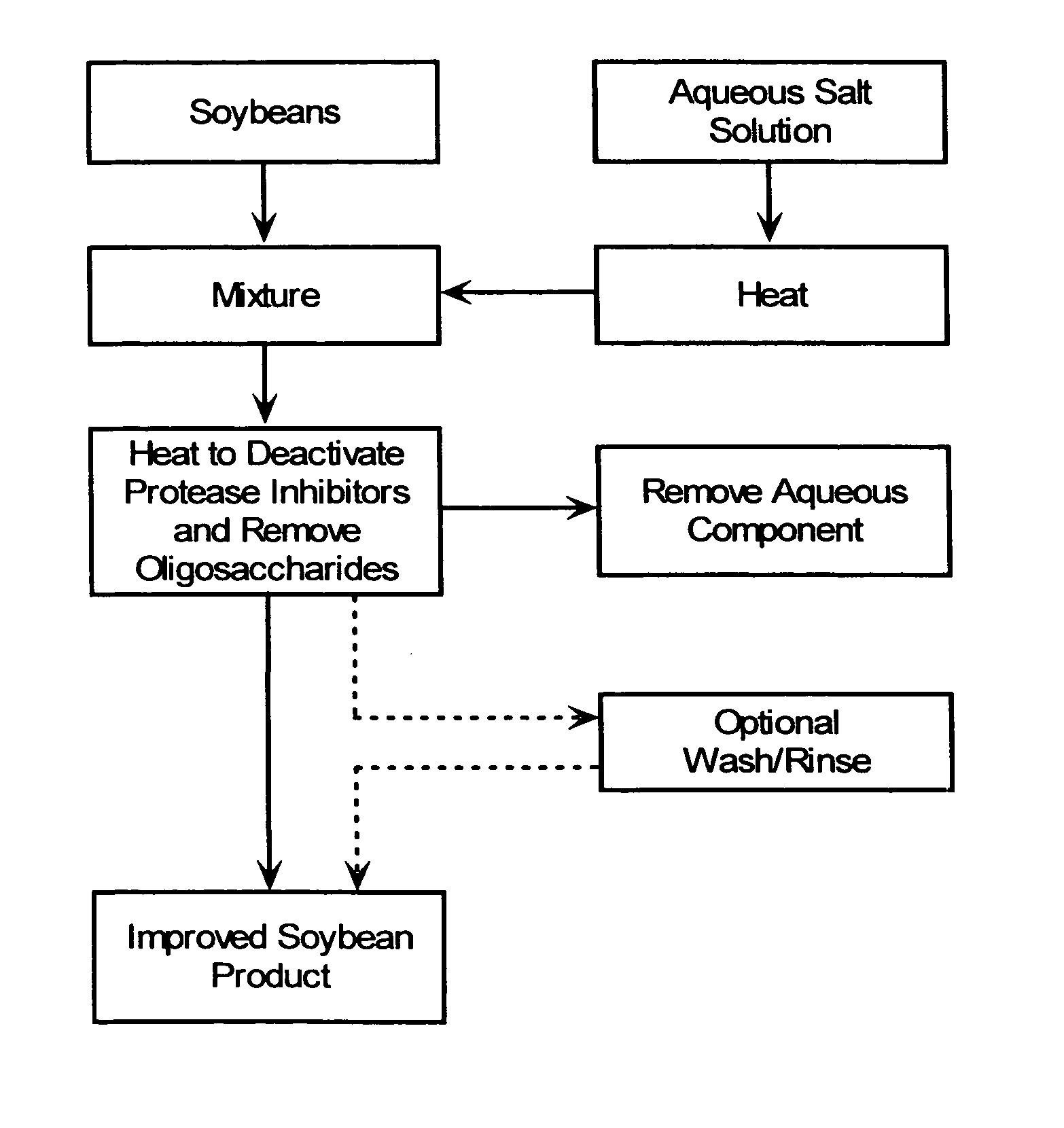

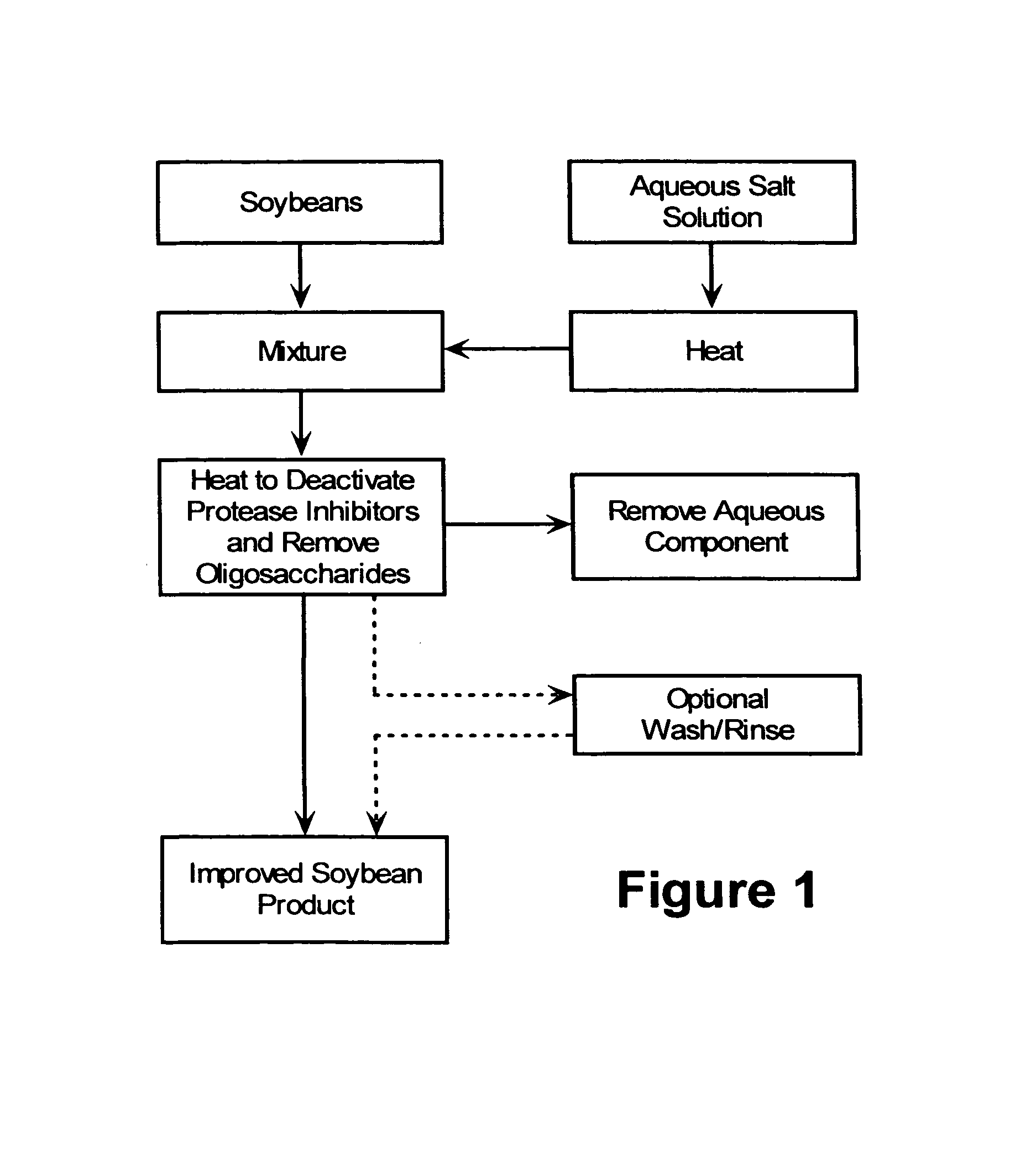

Method used

Image

Examples

example 1

[0027] In a steam-jacketed kettle, 50 g of natural gypsum (calcium sulfate dihydrate from US Gypsum, Ill.) and 10 liters of water were heated to a vigorous boil at about 100° C. Cleaned, dehulled soybeans (2 Kg) were added all at once to heated gypsum solution with gently mixing. The mixture was quickly brought back to boiling within about 2 minutes and kept at 100° C. for 1 hour. The mixture was poured onto a strainer in order to separate the free liquid. The heated soybeans were briefly rinsed with hot tap water and soaked in hot water at about 60 to about 80° C. for about 1 hour. The yield loss was about 12.5 percent. After cooling, treated beans were analyzed for gross chemical composition and enzyme activity (i.e., trypsin inhibitor and lipoxygenase) and compared with untreated starting material (i.e., control). The following results were obtained:

ControlInventiveProtein (%)4350Fat (%)2327Total Dietary Fiber (%)2421Soluble Dietary Fiber (%)1.4 1.7Insoluble Dietary Fiber (%)2...

example 2

[0029] Dehulled, whole soybeans were treated as in Example 1 except that after the treated soybeans were separated from the free liquid, they were briefly rinsed with cold tap water and then soaked in 20° C. water for about 2 hours. No lipoxygenase activity was found in the treated beans. After adding water to the treated beans (ratio of about 3.7:1), the mixture was ground to form a coarse slurry using a lab blender (Champ HP3, K-Tek, Utah) and then micromilled to form a smooth paste using a Dyno mill (2-pass). The micromilled soybeans was added to Ranch-type salad dressing up to 20 percent without any off-flavor. Improved flavor and tartness were also observed. The micromilled soybean product can be used as a fat mimetic,

example 3

[0030] A crunchy soy product similar to granola and free from undesirable soy oligosaccharides and beany off-flavor was prepared using dry, treated soybeans from Example 1. A binder syrup was prepared by mixing at 60° C. brown sugar (53%), water (28%), corn syrup (5%), fructose (6%), 10DE maltodextrin (5%), and sweet whey (3%). 1 part of the dry, treated soybeans were mixed with 0.18 part of melted vegetable shortening, followed by further mixing in 0.53 part of warm (60° C.) binder syrup. The resulting mixture can be spread and compacted on a baking sheet and dried at 121° C. in a convection oven for about 40 minutes followed by cooling to 20° C. to form a crunchy soy granola-type bar. Each 40 g bar will contain more than 10 g soy protein and, therefor, can be regarded as excellent source of protein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com