Optical multilayer disk, multiwavelength light source, and optical system using them

a multi-layer disk and optical technology, applied in the field of optical information recording mediums, can solve the problems of reducing light absorption aa and ac, difficulty in recording in the first recording medium, and lack of recording power with respect to the second recording medium, and achieve the effect of increasing the recording density considerably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

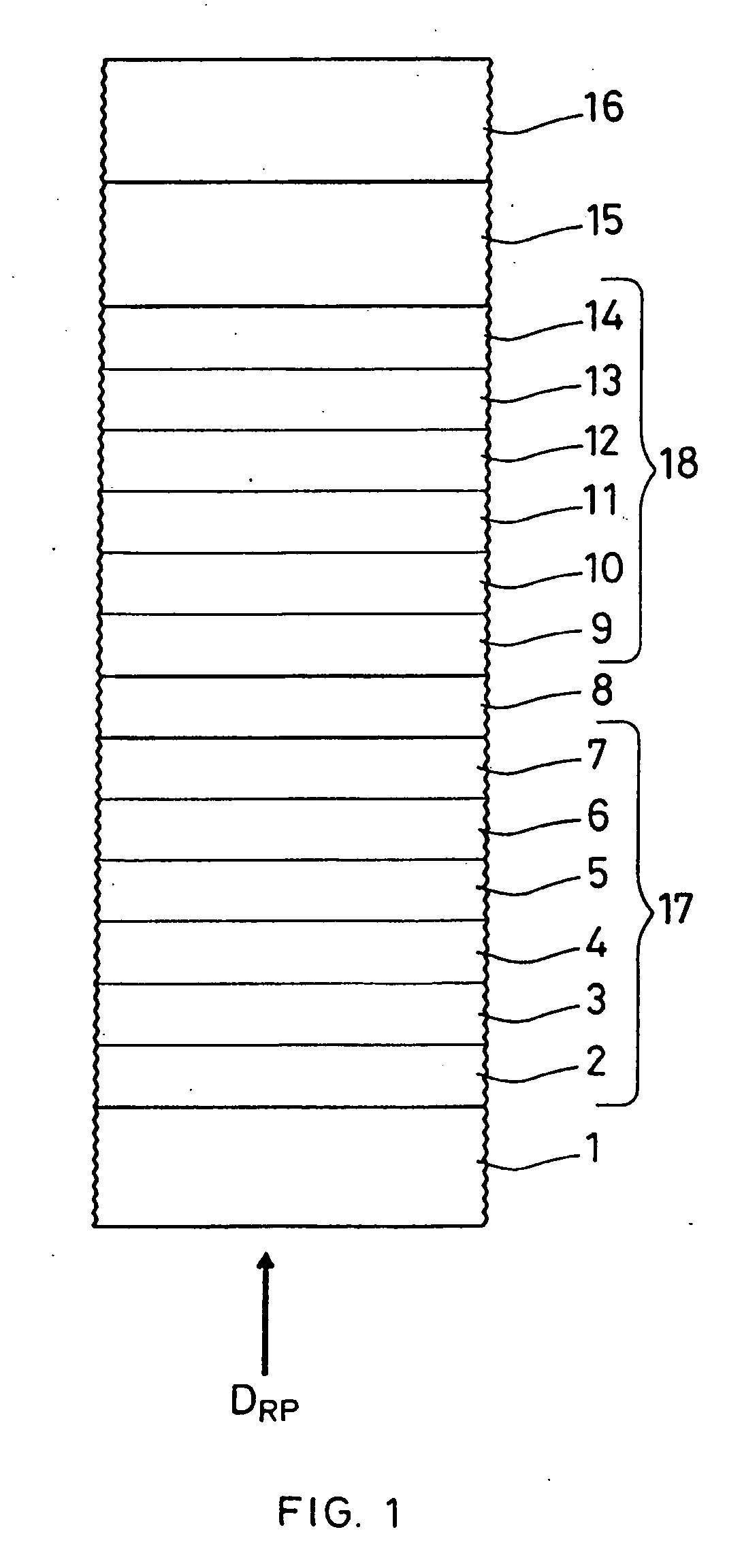

[0101]FIG. 1 shows a structural example of an optical information recording medium according to a first embodiment of the present invention. This optical information recording medium has the following configuration. On a substrate 1, a first lower optical interference layer 2, a first lower interface layer 3, a first recording layer 4, a first upper interface layer 5, a first upper optical interference layer 6, and a first reflective layer 7 are stacked sequentially. Subsequently, a separation layer 8 is provided on the first reflective layer 7. On the separation layer 8, a second lower optical interference layer 9, a second lower interface layer 10, a second recording layer 11, a second upper interface layer 12, a second upper optical interference layer 13, and a second reflective layer 14 are stacked sequentially. This stacked body is bonded to a dummy substrate 16 with an adhesion layer 15, thus forming the optical information recording medium. The multilayer structure from the f...

second embodiment

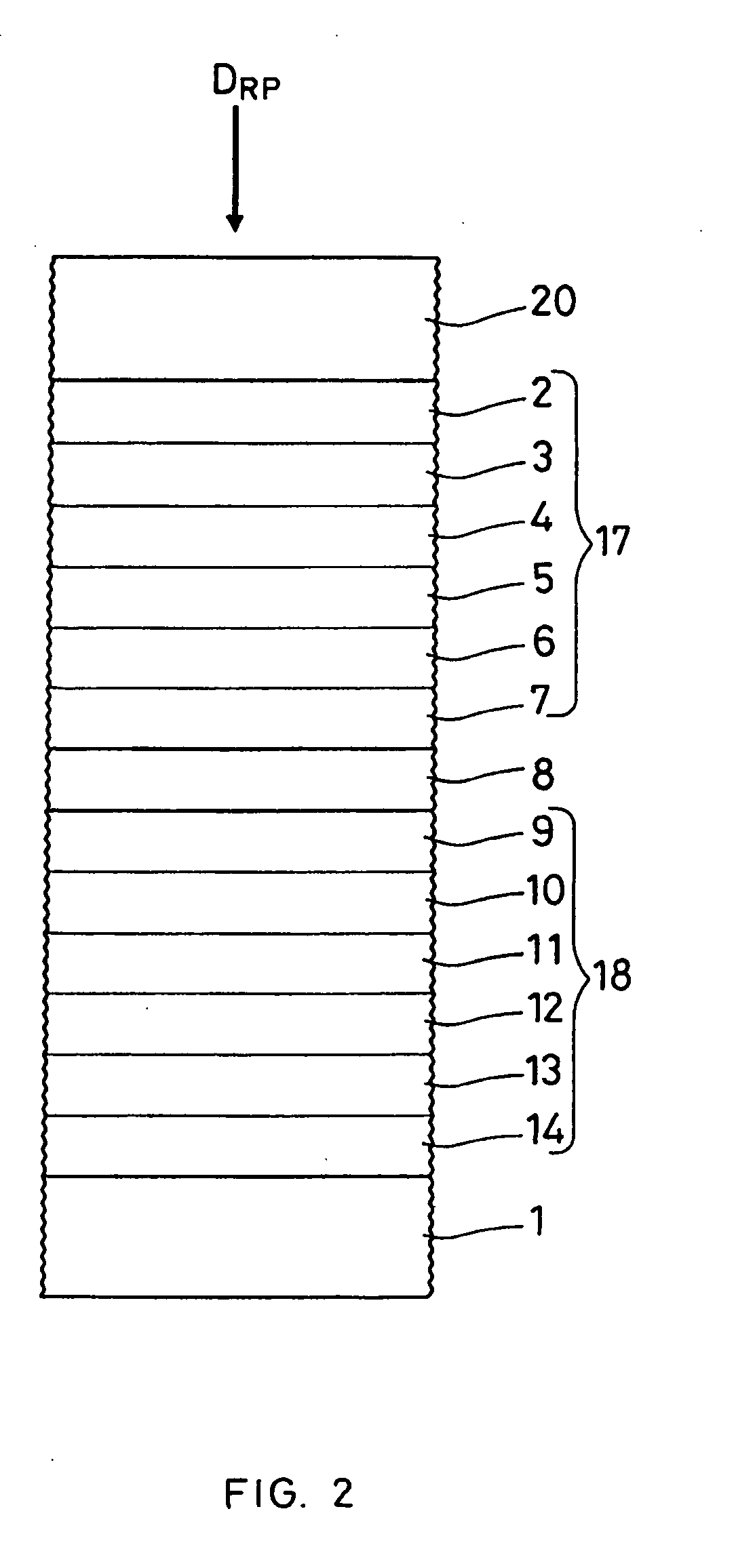

[0118]FIG. 2 shows a structural example of an optical information recording medium according to a second embodiment of the present invention. This optical information recording medium has the following configuration. On a substrate 1, a second reflective layer 14, a second upper optical interference layer 13, a second upper interface layer 12, a second recording layer 11, a second lower interface layer 10, and a second lower optical interference layer 9 are stacked sequentially. Subsequently, a separation layer 8 is provided on the second lower optical interference layer 9. On the separation layer 8, a first reflective layer 7, a first upper optical interference layer 6, a first upper interface layer 5, a first recording layer 4, a first lower interface layer 3, and a first lower optical interference layer 2 are stacked sequentially. On the first lower optical interference layer 2, a protective layer 20 is provided. The multilayer structure from the first lower optical interference ...

third embodiment

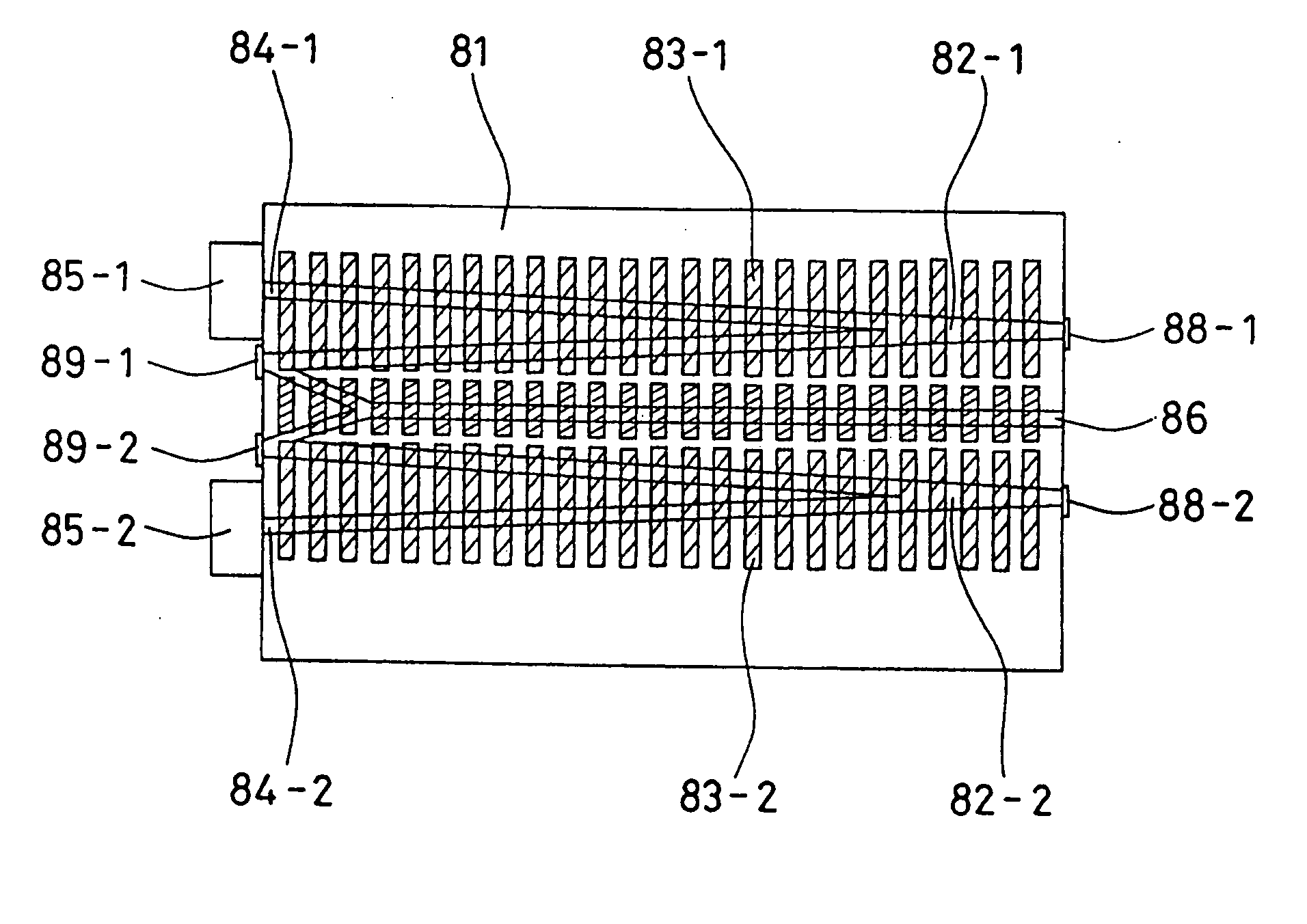

[0123]FIG. 3 shows a structural example of an optical information recording medium according to a third embodiment of the present invention. This optical information recording medium has the following configuration. On a substrate 21, a first lower optical interference layer 2, a first lower interface layer 3, a first recording layer 4, a first upper interface layer 5, a first upper optical interference layer 6, and a first reflective layer 7 are stacked sequentially. On a second substrate 22, a second reflective layer 14, a second upper optical interference layer 13, a second upper interface layer 12, a second recording layer 11, a second lower interface layer 10, and a second lower optical interference layer 9 are stacked sequentially. The multilayer structure from the first lower optical interference layer 2 to the first reflective layer 7 is a first recording medium 17. Similarly, the multilayer structure from the second lower optical interference layer 9 to the second reflectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com