Photoreduction method for metal complex ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

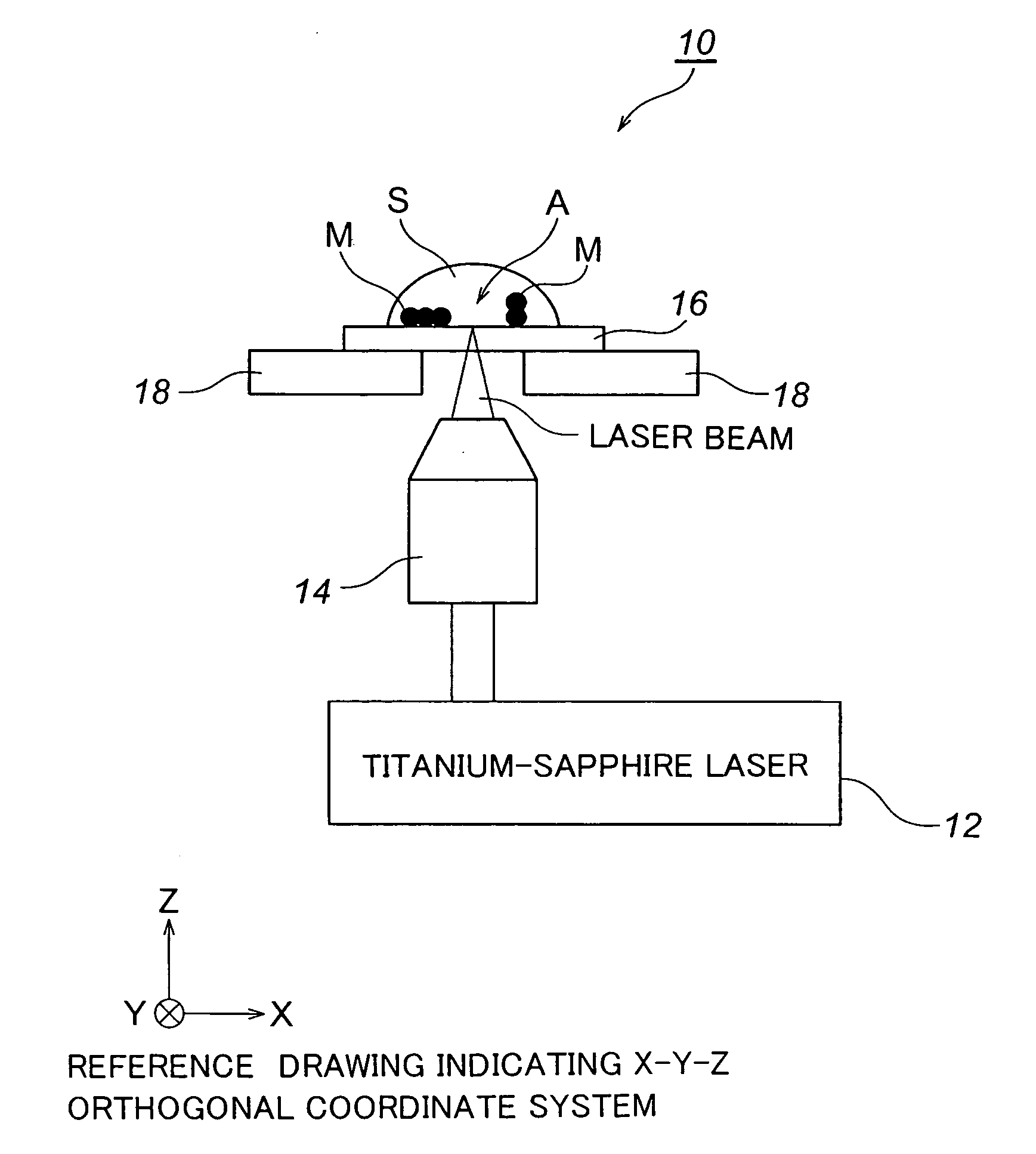

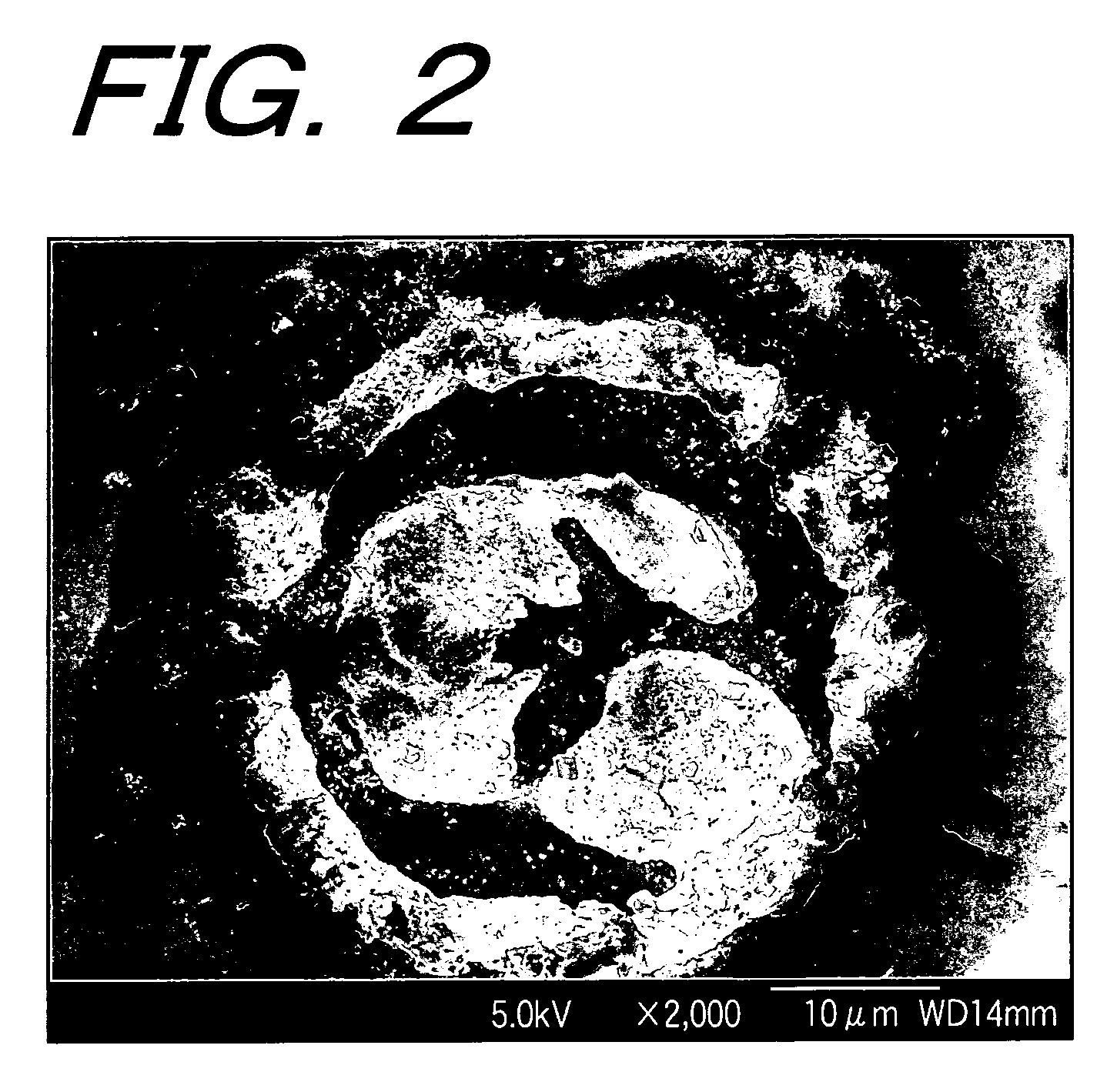

[0045]FIG. 2 is an electron micrograph showing the results of fabricating a silver structure in the case where a AgNO3 aqueous solution is used as the sample S, and the sample S is relatively scanned with the laser beam output from the titanium-sapphire laser 12 at a scanning speed 50 μm / s by means of the above-described optical system 10 wherein an illuminating radiation power is 78.5 mW with respect to the sample S.

[0046] On one hand, FIG. 3 is an electron micrograph showing the results of fabricating a silver structure in the case where a mixture prepared by dissolving Coumarin 440 into an ethanol solvent to a AgNO3 aqueous solution is used as the sample S, and the sample S is relatively scanned with the laser beam output from the titanium-sapphire laser 12 at a scanning speed 50 μm / s by means of the above-described optical system 10 wherein a concentration of Coumarin 440 is 0.02 wt % with respect to the ethanol solvent, while an illuminating radiation power is 14.3 mW with res...

example 2

[0049]FIG. 4 is an optical micrograph showing the results of fabricating a gold structure in the case where a HAuCl4 aqueous solution is used as the sample S, and the sample S is relatively scanned with the laser beam output from the titanium-sapphire laser 12 at a scanning speed 50 μm / s by means of the above-described optical system 10 wherein an illuminating radiation power is 142.9 mW with respect to the sample S.

[0050] On one hand, FIG. 5 is an optical micrograph showing the results of fabricating a gold structure in the case where a mixture prepared by dissolving Coumarin 481 into a dimethylformamide solvent to a HAuCl4 aqueous solution is used as the sample S, and the sample S is relatively scanned with the laser beam output from the titanium-sapphire laser 12 at a scanning speed 50 μm / s by means of the above-described optical system 10.

[0051] In this case, a concentration of Coumarin 481 is 0.1 wt % with respect to the dimethylformamide solvent, while an illuminating radiat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Metallic bond | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com