Semiconductor light-emitting device and method for fabricating the same

a semiconductor and light-emitting device technology, applied in the direction of suction cups, mechanical equipment, fastening means, etc., can solve the problems of low external quantum efficiency of nitride compound semiconductors, low light extraction efficiency, etc., to reduce fabrication throughput and cost, high efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

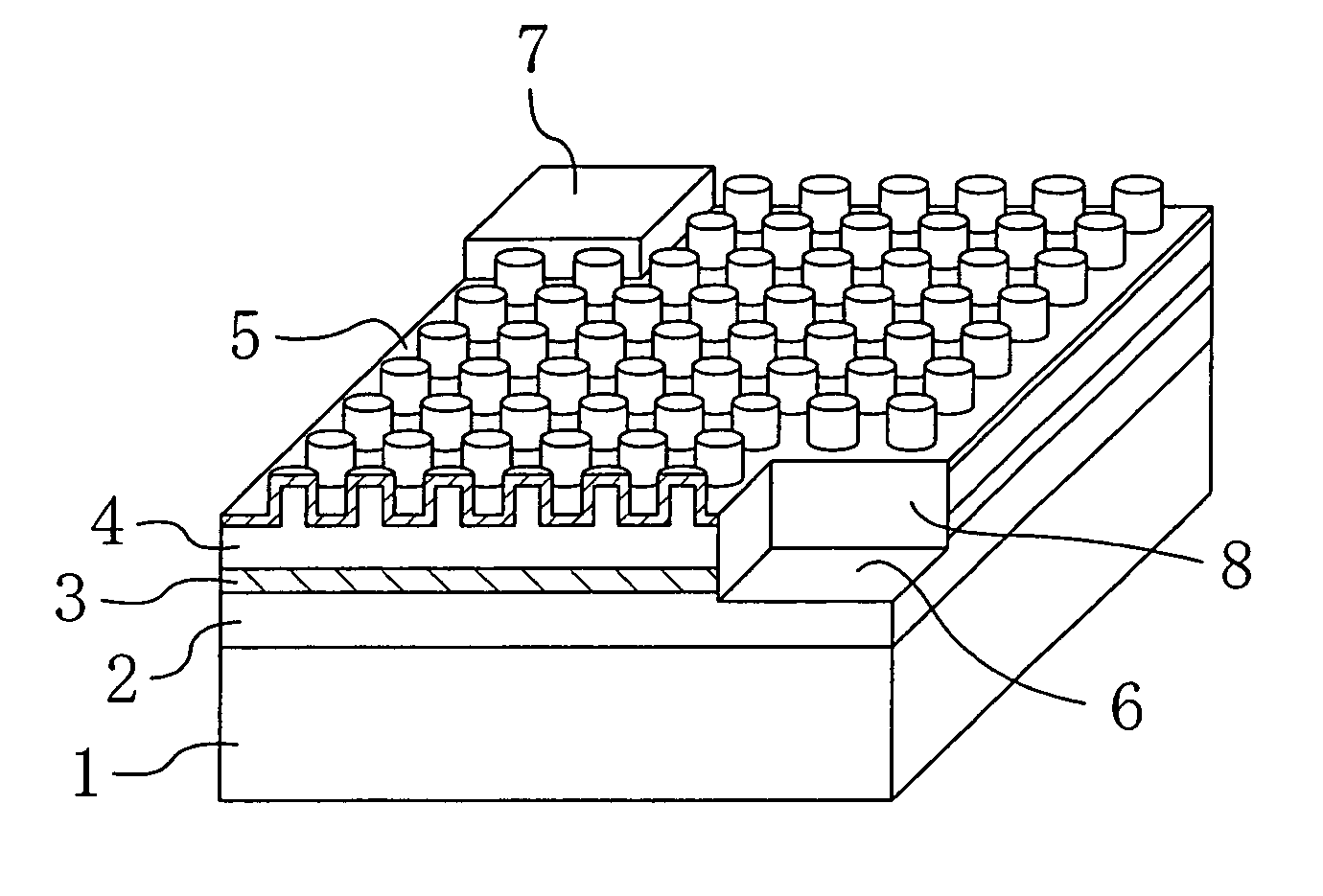

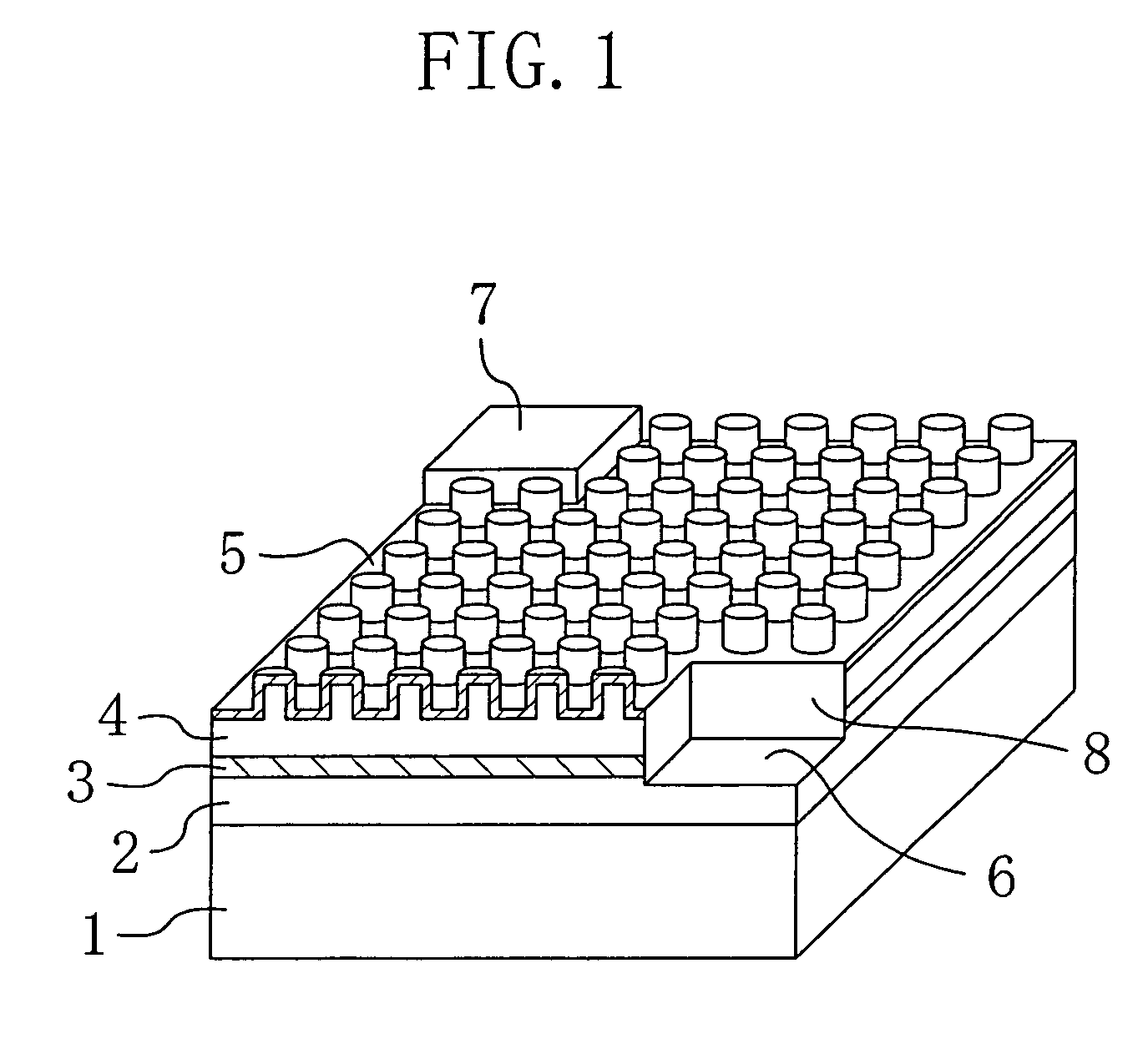

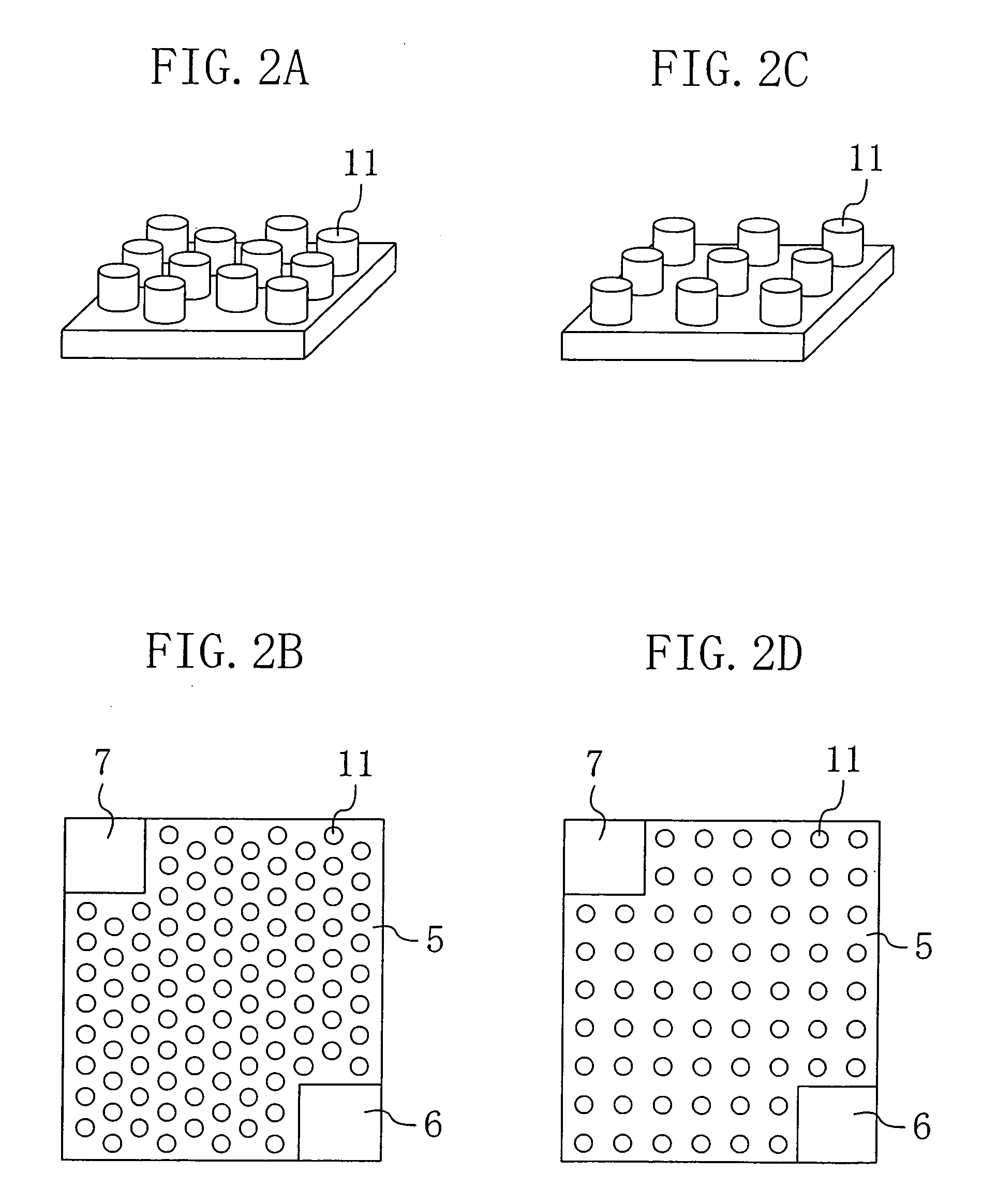

[0048]FIG. 1 is a perspective view showing a structure of a semiconductor light-emitting device according to a first embodiment of the present invention. As shown in FIG. 1, the semiconductor light-emitting device according to the present embodiment is an LED comprising: a sapphire substrate 1; a non-doped GaN buffer layer (not shown) provided on the sapphire substrate 1 and having a thickness of 30 nm; an n-type GaN layer 2 provided on the GaN buffer layer, doped with an n-type impurity at a concentration of 2×1018 cm−3, and having a thickness of 2 μm; an InGaN active layer 3 provided on the n-type GaN layer 2, made of non-doped In0.45Ga0.55N with a PL (photoluminescence) peak wavelength of 450 nm, and having a thickness of 3 nm; and a p-type GaN layer 4 doped with a p-type impurity at a concentration of 7×1017 cm−3 and having a thickness of 400 nm. These nitride compound semiconductors are formed by crystal growth such as MOCVD (Metal-Organic Chemical Vapor Deposition) or MBE (Mol...

embodiment 2

[0066]FIG. 13 is a perspective view showing a structure of a semiconductor light-emitting device according to a second embodiment of the present invention. As shown in FIG. 13, the semiconductor light-emitting device according to the present embodiment is an LED comprising: a sapphire substrate 1; a non-doped GaN buffer layer (not shown) provided on the sapphire substrate 1 and having a thickness of 30 nm; an n-type GaN layer 2 provided on the GaN buffer layer, doped with an n-type impurity at a concentration of 2×1018 cm−3, and having a thickness of 2 μm; an InGaN active layer 3 provided on the n-type GaN layer 2, made of non-doped In0.45Ga0.55N with a PL peak wavelength of 450 nm, and having a thickness of 3 nm; and a p-type GaN layer 4 provided on the InGaN active layer 3, doped with a p-type impurity at a concentration of 7×1017 cm3, and having a thickness of 200 nm.

[0067] A trench 8 for exposing the n-type GaN layer as the upper surface thereof has been formed by partly etchin...

embodiment 3

[0072]FIG. 14 is a perspective view showing a structure of a semiconductor light-emitting device according to a third embodiment of the present invention. As shown in FIG. 14, the semiconductor light-emitting device according to the present embodiment is an LED comprising: a sapphire substrate 1; a non-doped GaN buffer layer (not shown) provided on the sapphire substrate 1 and having a thickness of 30 nm; an n-type GaN layer 2 provided on the GaN buffer layer, doped with an n-type impurity at a concentration of 2×1018 cm−3, and having a thickness of 2 μm; an InGaN active layer 3 provided on the n-type GaN layer 2, made of non-doped In0.45Ga0.55N at a PL peak wavelength of 450 nm, and having a thickness of 3 nm; and a p-type GaN layer 4 provided on the InGaN active layer 3, doped with a p-type impurity at a concentration of 7×1017 cm−3, and having a thickness of 200 nm. These nitride compound semiconductors are formed by crystal growth such as MOCVD or MBE.

[0073] A trench 8 for expo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com