Silver ternary alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

Production and Properties of Investment Cast Strip

[0048] The molten alloy of Example 1 is formed into strip by investment casting. The resulting strip is substantially free of “hot short” defects and brittleness, and has a hardness of 63.5 HV.

example 3

Solvent Dip Cleaning (Solvent Degreased Samples)

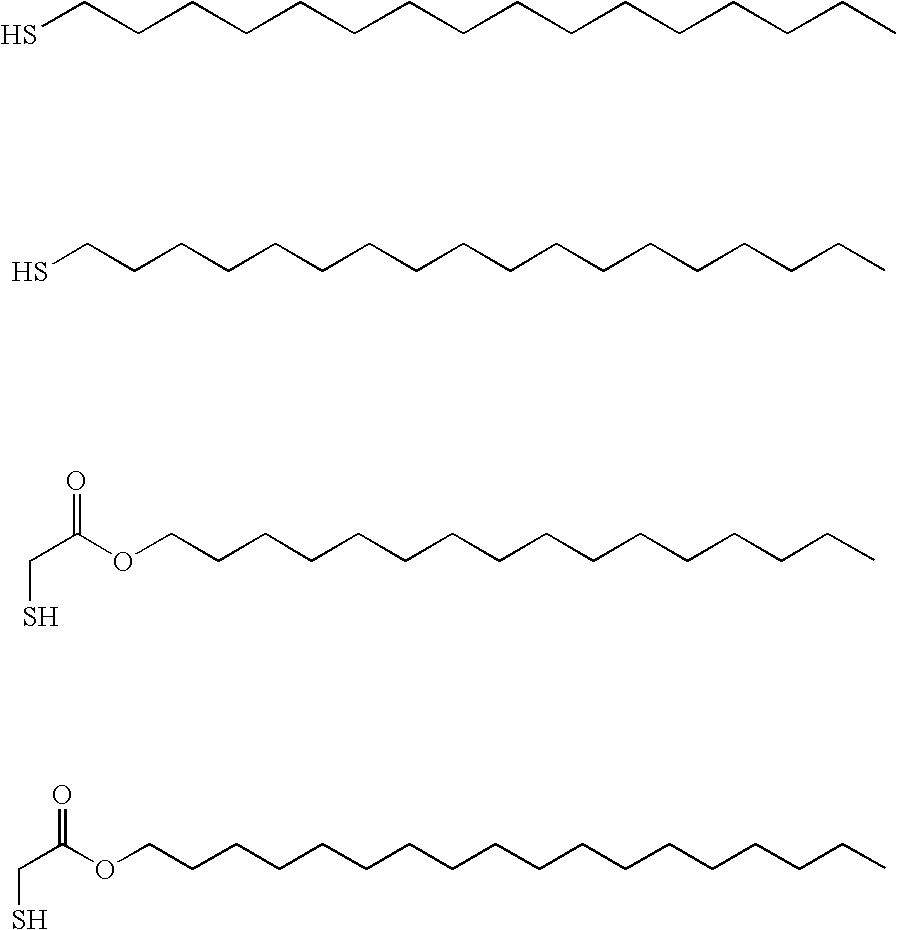

[0049] Solutions are made up containing stearyl mercaptan (0.1, 0.5 and 1.0 gram) in EnSolv 765 (100 ml). Samples of the rolled annealed ternary alloy sheet of Example 1 which have been polished and ultrasonically degreased in EnSolv 765 for 2 minutes are each immersed in one of the stearyl mercaptan solutions for periods of 2 minutes, 5 minutes and 15 minutes. The samples are then buffed with clean cotton wool.

[0050] In order to evaluate tarnish resistance, the alloy samples are supported on a glass slide in a fume cupboard about 25 mm above the surface of 20% ammonium polysulphide solution so as to be exposed to the hydrogen sulphide that arises from that solution. All of the samples demonstrate good tarnish resistance during a one-hour test, with very slight yellowing after 45 minutes exposure to the hydrogen sulphide. The light film on the samples is easily removed with a cleaning cloth impregnated with stearyl mercaptan.

[0051] ...

example 4

Effect of Post-Treatment Solvent Cleaning

[0052] Example 3 is repeated for the ternary alloy samples except that instead of buffing with cotton wool after the mercaptan treatment, the samples are ultrasonically degreased in EnSolv 765 for 2 minutes. The samples are then tarnish tested as described in Example 3 and all show enhanced tarnish resistance. The ability of the protective effect of the stearyl mercaptan treatment to survive ultrasonic cleaning in EnSolv suggests that the tarnish resistance is achieved by a surface reaction involving the stearyl mercaptan and possibly the germanium in the present alloy, and not by formation of a grease or oil layer on the surface of the present alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com