Turbine housing and floatation assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

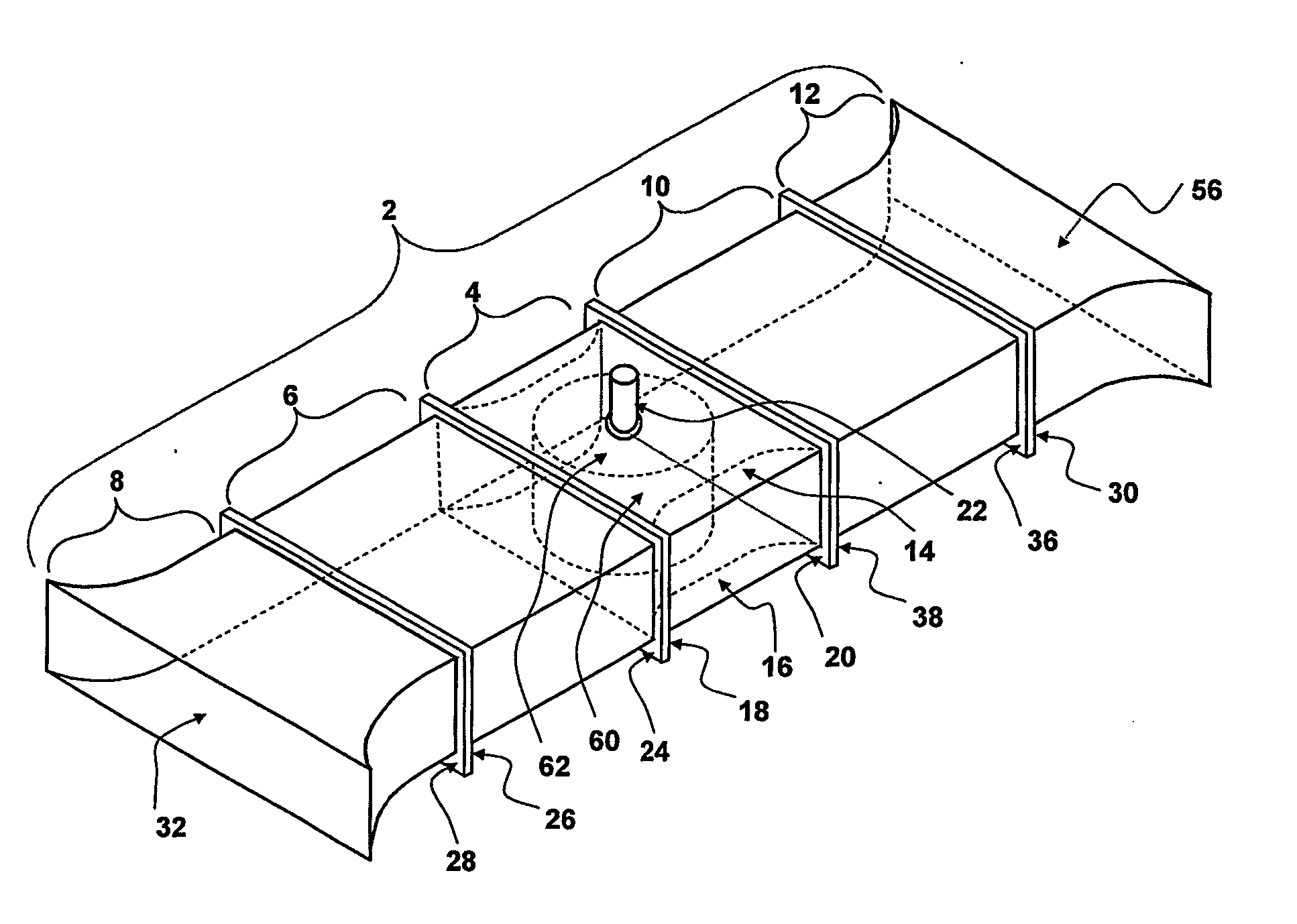

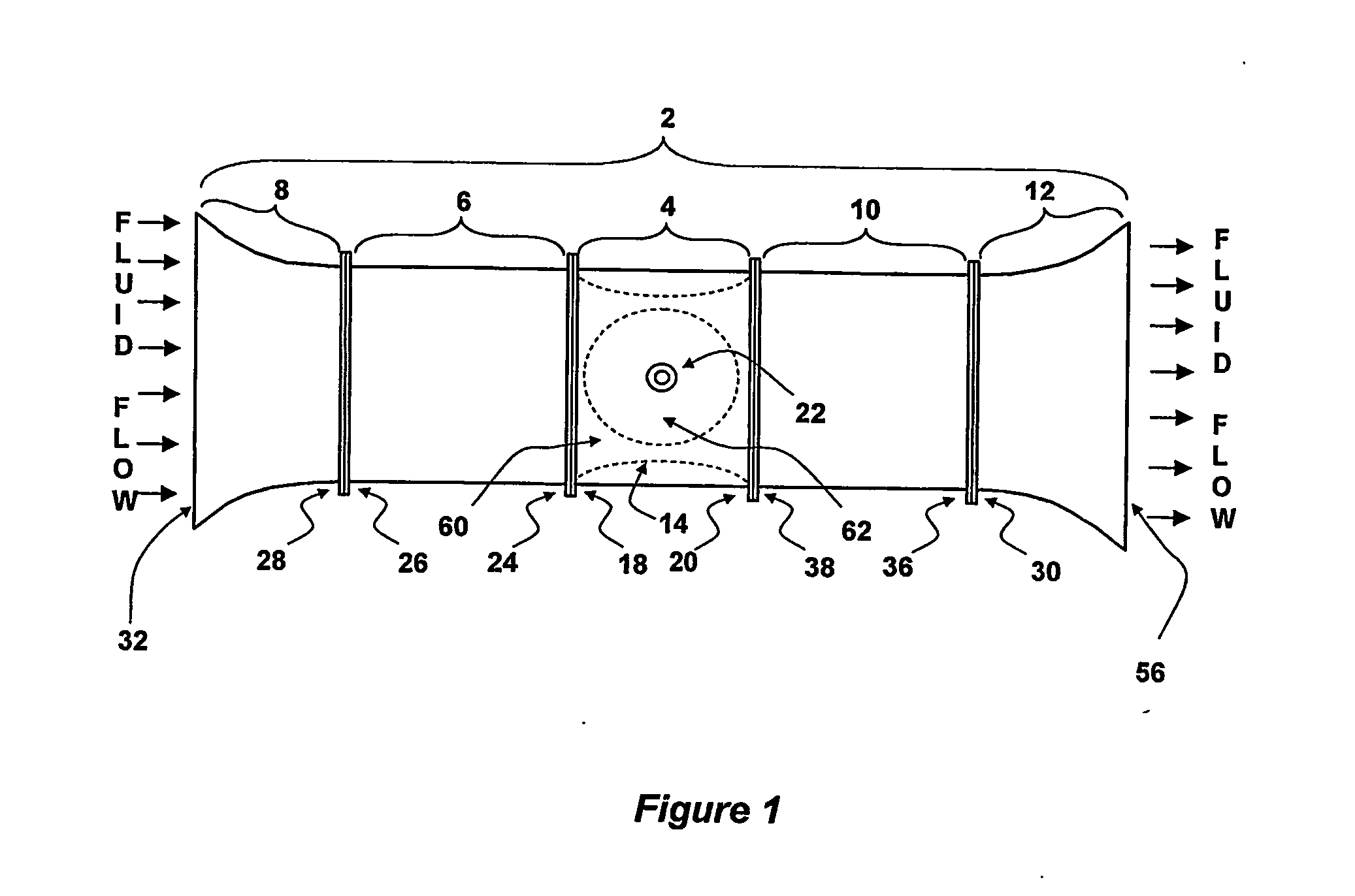

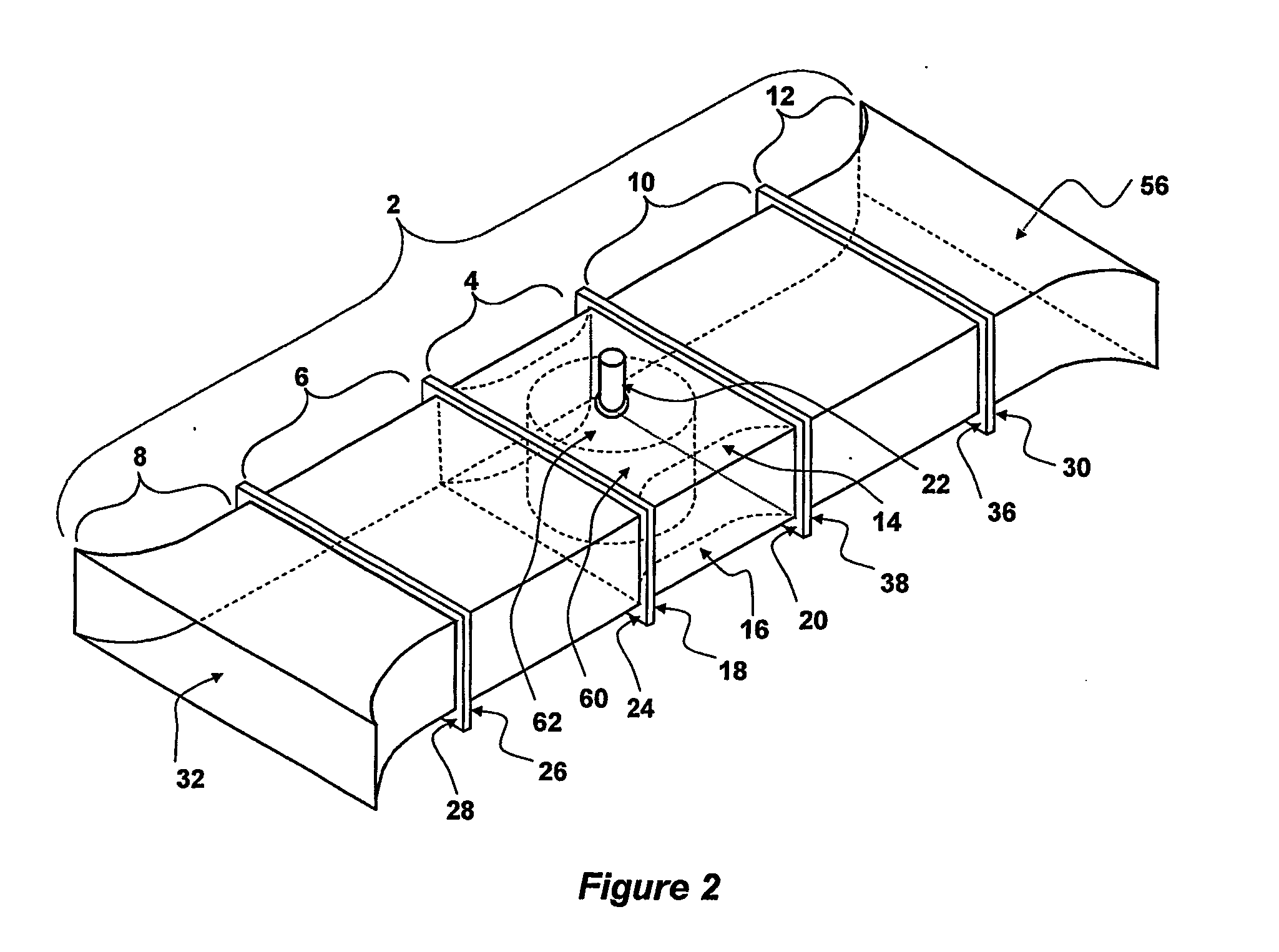

Image

Examples

second embodiment

[0066] Referring now to FIGS. 3 and 4, the turbine housing 2, includes all the elements of the embodiment described for FIGS. 1 and 2, but also includes means to manage the fluid flow entering the turbine housing portion 4, in the foprm of fluid flow restriction means in the form of plates 34 and 40 installed inside the conducting duct portions 6 and 10. The fluid flow restriction means 34 and 40 are either straight rectangular plates, or are curvelinear plates, shaped to form a smooth curvature to guide, increase the speed, and direct the flow of the fluid. When the inlet portion 8 opening 32 is facing the fluid flow, the entering fluid increases in speed as it passes through the narrowing space of the bore of the inlet portion 8. The fluid enters the conducting unit 6, passing along the outward face 90 of the plate 34, the fluid speed increases further and is directed to hit the blades / buckets of turbine 62 where it is most needed, to produce optimum power extraction. Afterwards, ...

third embodiment

[0073] Referring now to FIGS. 5, 6, 7, and 8, the turbine housing 2 of the invention, includes all elements described in FIGS. 3 and 4, but include floatation assembly 80 to make the turbine housing 2 float. The floatation assembly 80, is composed of at least one floatation unit 82, preferably, at least two floatation units 82, separated by superstructure and flooring 84, such that when the two floatation units 82 are bolted and joined, the turbine housing 2, will be mounted to straddle the floatation assembly80, sandwiching the whole body lengthwise. When bolted to the superstructure and flooring 84, the turbine housing 2 becomes an integral unit of the turbine housing and floatation assembly 94. Mounting is made such that, the turbine housing 2 is lower than the top of the superstructure and flooring 84, suitably to make it totally underwater while the super structure and flooring 84 is well above the water.

[0074] On top of the superstructure and flooring 84 is where the turbine g...

fourth embodiment

[0077] Referring now to FIGS. 8 and 9, the invention includes all the elements of the embodiment described for FIGS. 5, 6, 7, and 8, but includes means to submerge the whole turbine housing and floatation assembly 94 to continuously operate; this time under the surface of the water.

[0078] At least one mechanically / electrically or pneumatically controlled discharge valve 72 and at least one mechanically / electrically or pneumatically controlled charging valve 74 is installed on the top surface of the floatation unit 82.

[0079] In use, during normal operating condition, except for the flooring 84, the rest of the floatation means assembly 80 is submerged under the water surface.

[0080] During bad weather condition water surface becomes rough. The continuously buffeting disturbances cause by the waves, disrupts the smooth operation of the system. To avoid the possibility of a mooring break or destruction, the whole turbine housing and floatation assembly 94 is required to submerge to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com