High performance cooling assembly for electronics

a cooling assembly and high-performance technology, applied in the field of electronic circuit board cooling systems, can solve the problems of low density of air, poor thermal conductivity compared to other materials, and difficult cooling of certain configurations of electronic circuits, and achieve the effect of high performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

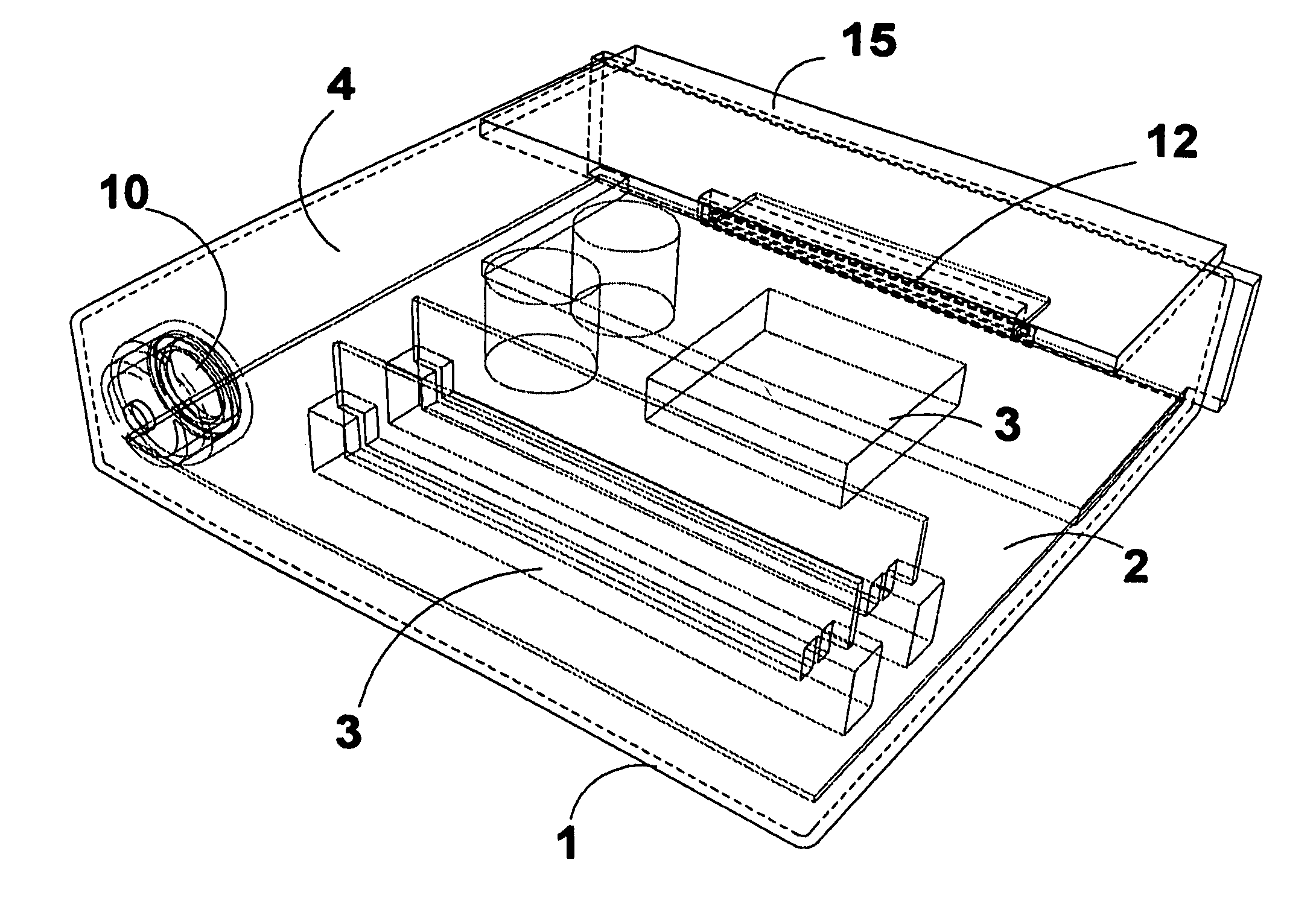

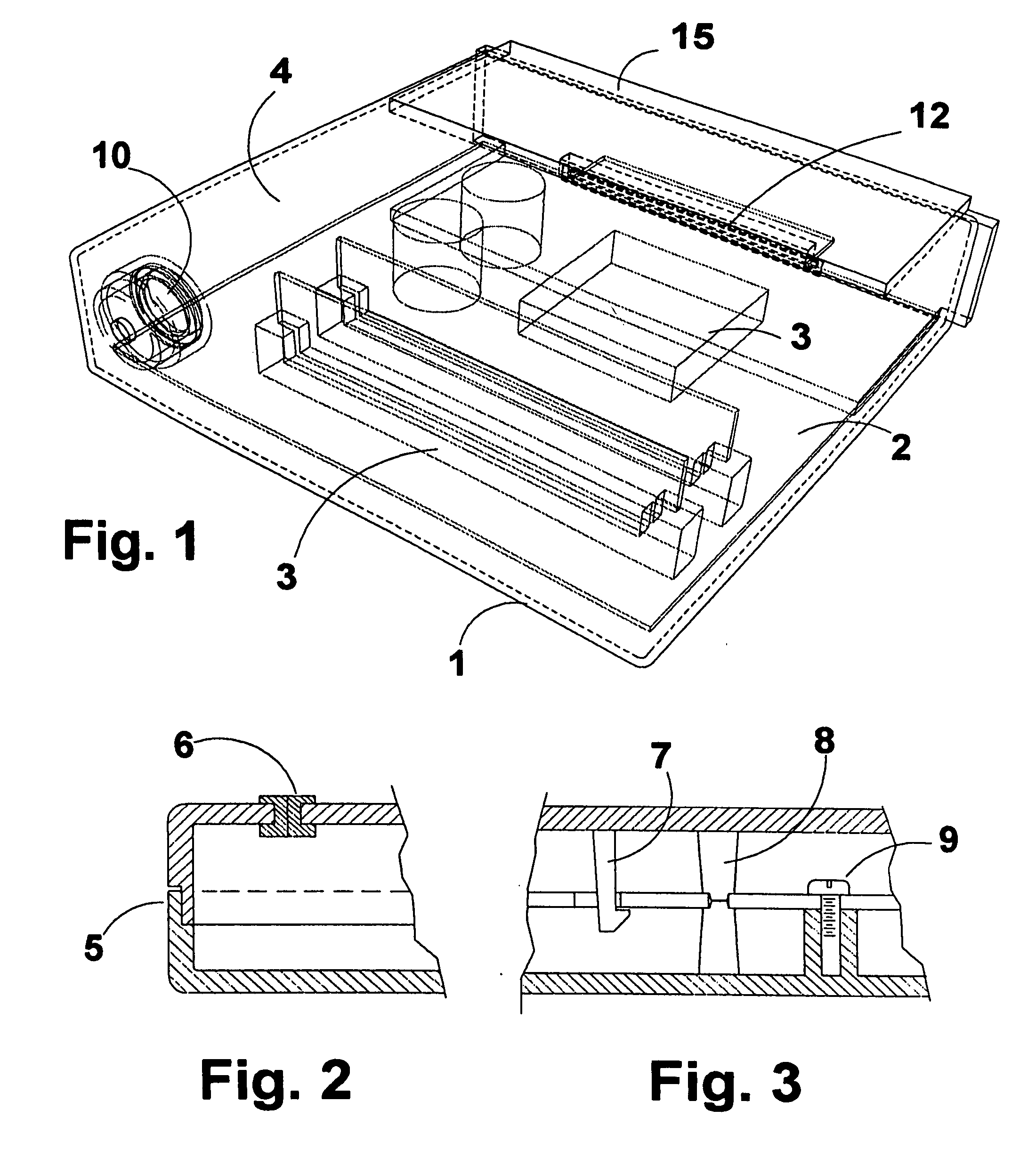

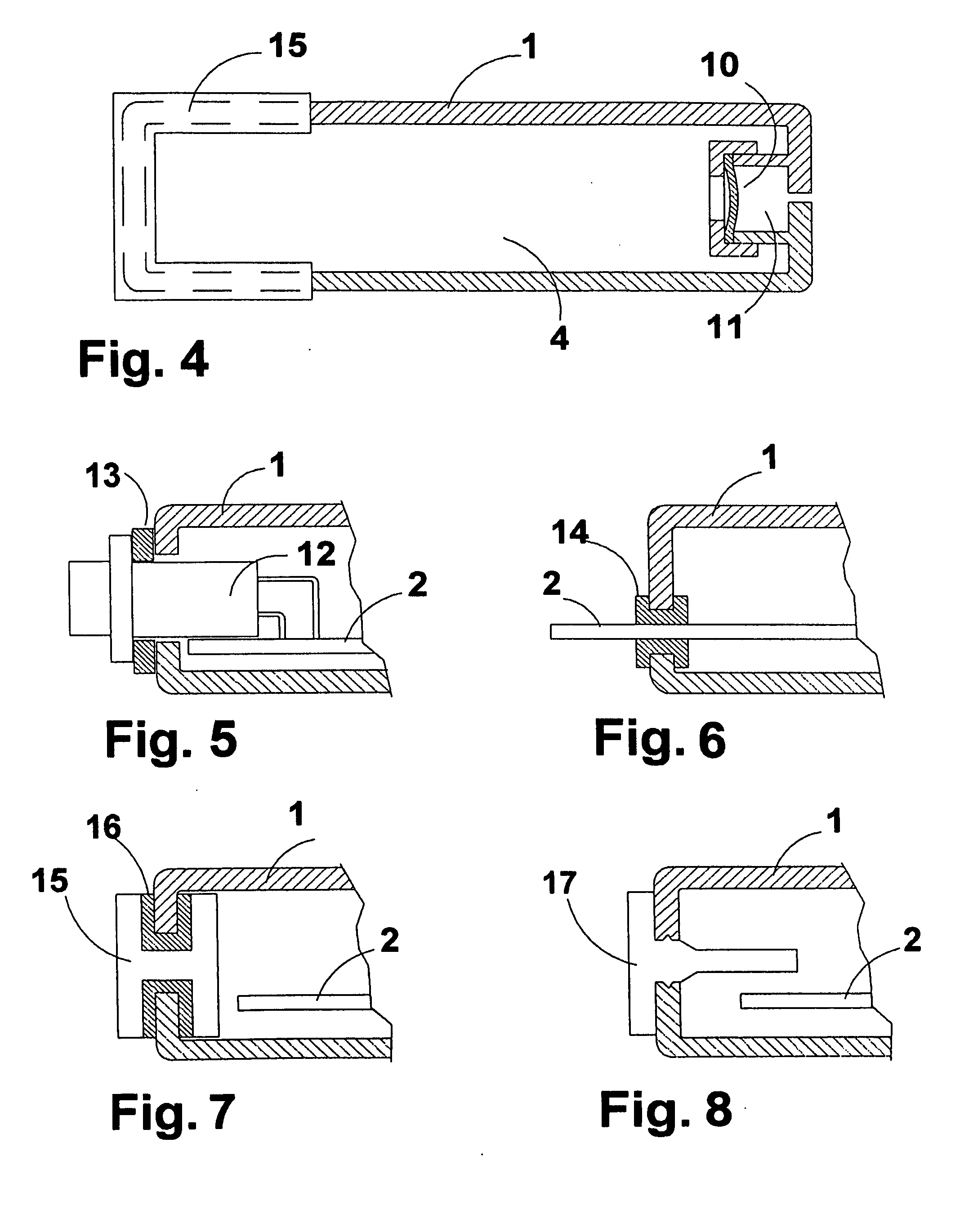

[0070] The present invention provides advantageous devices and methods for cooling complex and often rather large, electronics assemblies. In many cases, the electronic assemblies are or include circuit boards. As explained herein, the devices utilize thermally conductive, dielectric liquid-filled containers in which circuit boards or other complex electronic devices are mounted. The heat generated by components on the circuit board or other complex device is conducted through the liquid and through a thermally conductive plate that extends from the interior of the container in contact with the liquid to the exterior of the container, thereby providing an efficient heat conduction pathway. From the exterior surface of the plate, the heat can be conducted or dissipated away from the container.

[0071] Additional advantageous features of such devices relate to compensating for thermal expansion of the large volume of liquid in the container, the mechanisms used to thermally couple the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com