Method for purification of indole derivative trimer, electrode active substance comprising the purified trimer, method for manufacturing the electrode active substance, and electrochemical cell using the same

a technology of indole derivatives and active substances, which is applied in the direction of electrochemical machining apparatus, electrochemical manufacturing processes, acid electrolytes, etc., can solve the problems of increasing leak current, difficult to manufacture products in large quantities, and hardly applied industrial manufacturing methods, etc., to achieve excellent leak current characteristics, simple removal of metal impurities, effect of effective and effective removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

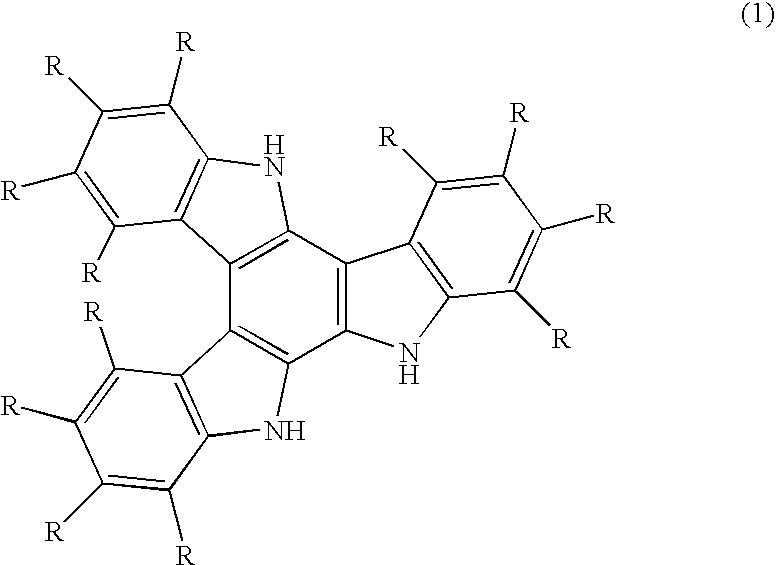

manufacture example 1 (

Manufacture of an Indole Derivative Trimer)

[0067] In a three-neck flask of 200 μml, 10 μml of acetonitrile was charged; and 1.42 g of a methyl indole-6-carboxylate monomer was dissolved therein. On the other hand, for preparing an oxidizing agent solution, 16.2 g of ferric chloride anhydride and 5.4 g of water were added to and dissolved in 40 ml of acetonitrile, and agitated for 10 minutes. Then, the prepared oxidizing agent solution was added dropwise into the acetonitrile solution of the methyl indole-6-carboxylate monomer in 30 minutes, and thereafter agitated for 10 hours at 60° C. The reaction solution turned from pale yellow to green. The reaction was stopped at this point; the reaction solution was conducted to suction-filtration, washed with acetonitrile at ordinary temperature, then with methanol, and dried in the air at 120° C. for 5 hours to obtain 1.12 9 of trimethyl 6,11-dihydro-5H-diindolo[2,3-a:2′,3′-c]carbazole-3,8, 13-tricarboxylate (methyl indole-6-carboxylate tri...

example 1

[0069] About 1 g of the trimer obtained in Manufacture Example 1 was transferred to a beaker of 200 ml; 15 g of a 5 wt. %sulfuric acid aqueous solution as the solvent was charged therein; the mixture solvent was agitated at ordinary temperature for 5 minutes; and the heater temperature was raised to 180° C. and held for 30 minutes. The mixture solvent was mixed with 8 g of 1H-imidazole, and further held at the same temperature for 10 minutes with agitating. Thereafter, the trimer was separated from the solvent by suction-filtration; and the filtered trimer was slightly washed with boiling water, and dried to obtain pale-green crystals. The filtrate was yellow.

example 2

[0070] Example 2 was performed as in Example 1, but using a sulfuric acid aqueous solution of 20 wt. %as the solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com