Particles, aqueous dispersion and film of titanium oxide, and preparation thereof

a technology of titanium oxide and aqueous dispersion, which is applied in the field of particles, aqueous dispersion and film of titanium oxide, and preparation thereof, can solve the problems of difficult to obtain fine brookite-type titanium oxide crystal particles, difficult to stably produce brookite-type titanium oxide inability to form fine brookite-type titanium oxide particles in liquid phase process, etc., to achieve excellent photocatalytic activity, improve transparency and adh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0068] The present invention is now described with reference to examples of the present invention, to which the present invention is, of course, not limited.

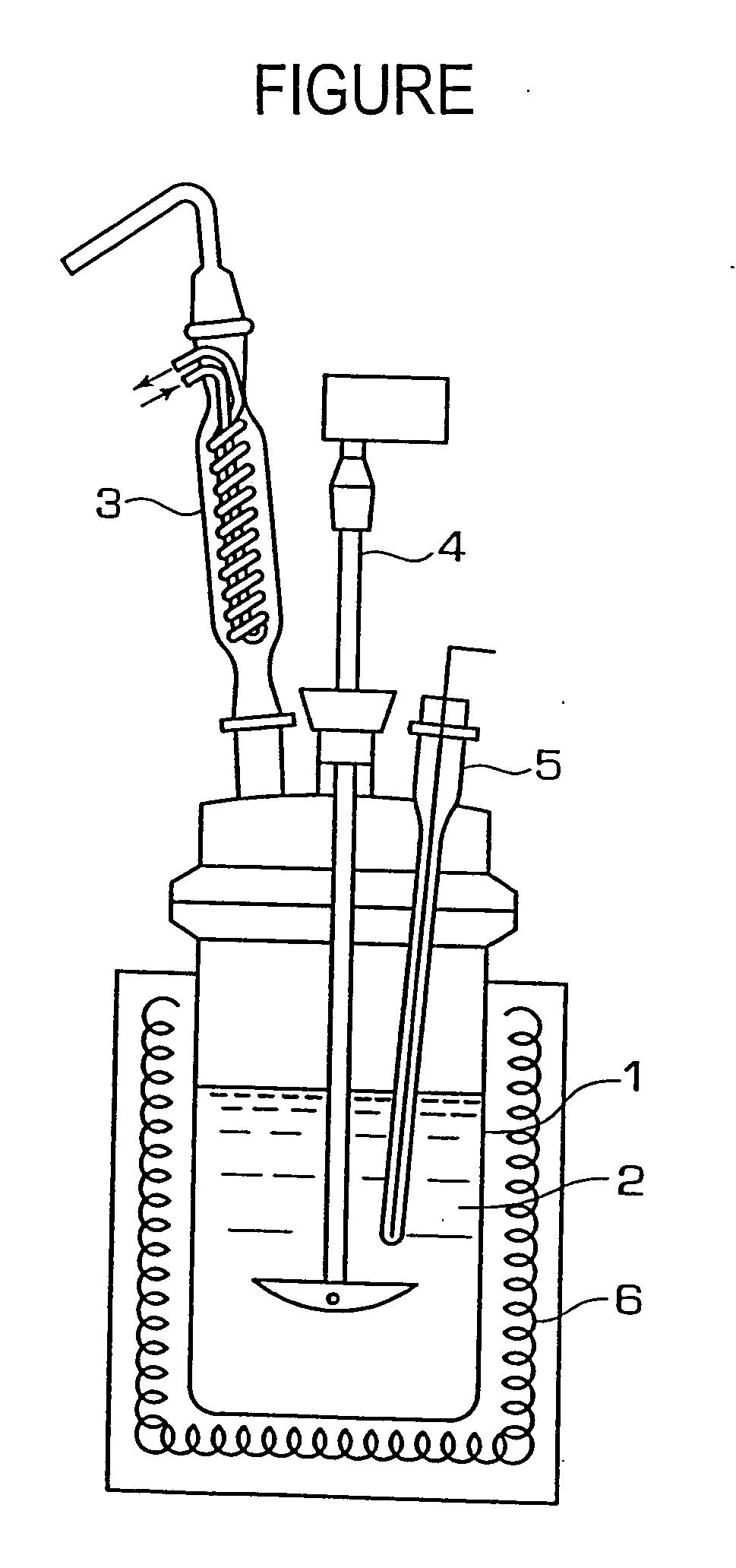

examples 1 to 6

[0069] Water was added to titanium tetrachloride (purity: 99.9%) to-control the concentration of titanium tetrachloride of the solution to 0.25 mol / l (reduced to titanium oxide: 2% by weight), while the aqueous solution was cooled by a cooler such as ice to prevent the temperature of the solution from exceeding 50° C. One liter of the aqueous solution was charged in a reactor equipped with a reflux cooler as shown in the FIGURE and heated to the boiling point (104° C.) of the solution and hydrolysis was conducted for 60 minutes by maintaining that temperature. The obtained sol was cooled and then subjected to electrodialysis to remove chloride produced in and remaining after the reaction to the chloride ion concentrations as shown in Table 1. The electrodialysis was carried out using an electrodialysis device G3, manufactured by Asahi Kasei Kogyo K.K., while the pH of the sol was monitored.

[0070] Observation of the particles in the sols demonstrated that the average particle sizes ...

example 9

[0083] 954 ml of distilled water was charged in a reactor equipped with a reflex cooler as shown in the FIGURE and heated to 95° C. While the stirring rate was kept to about 200 rpm, 46 ml of an aqueous solution of titanium tetrachloride (titanium element content: 16.3% by weight; density: 1.59; purity: 99.9%) was added dropwise into the reactor at a rate of about 5 ml / min. The temperature of the reaction solution was kept constant during the reaction. As a result, the concentration of titanium tetrachloride was changed to 0.25 mol / l (reduced titanium oxide concentration: 2% by weight).

[0084] In the reactor, the reaction solution became clouded soon after starting the addition of titanium tetrachloride, but the temperature of the reaction solution was kept constant and, after finishing the addition, raised to near the boiling point (104° C.) and kept at this temperature for 60 minutes to complete and finish the reaction. After cooling, produced and remaining chlorine was removed by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| energy gap | aaaaa | aaaaa |

| energy gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com