Metal-based carbon fiber composite material and method for producing the same

a carbon fiber and composite material technology, applied in the field of metal-based carbon fiber composite materials, can solve the problems of carbon fibers reacting with metals, increasing the amount of heat generated by equipment, and generating metal carbides, and achieves the effects of low weight, high thermal conductivity, and inhibiting the formation of metal carbides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0054] To a rod mill having an inner diameter of 13 mm was added 6 grams of aluminum powder having a mean particle diameter of 30 μm (available from Kishida Chemical Co., Ltd. ), 3 grams of pitch-based carbon fiber having a fiber length of 20 μm and a diameter of 10 μm (available from Nippon Graphite Fiber Corporation, YS-95A) and a glass rod (5 mm in diameter×20 mm in length). The rod mill was rotated along its axis to mix the ingredients, thereby obtaining a metal fiber mixture.

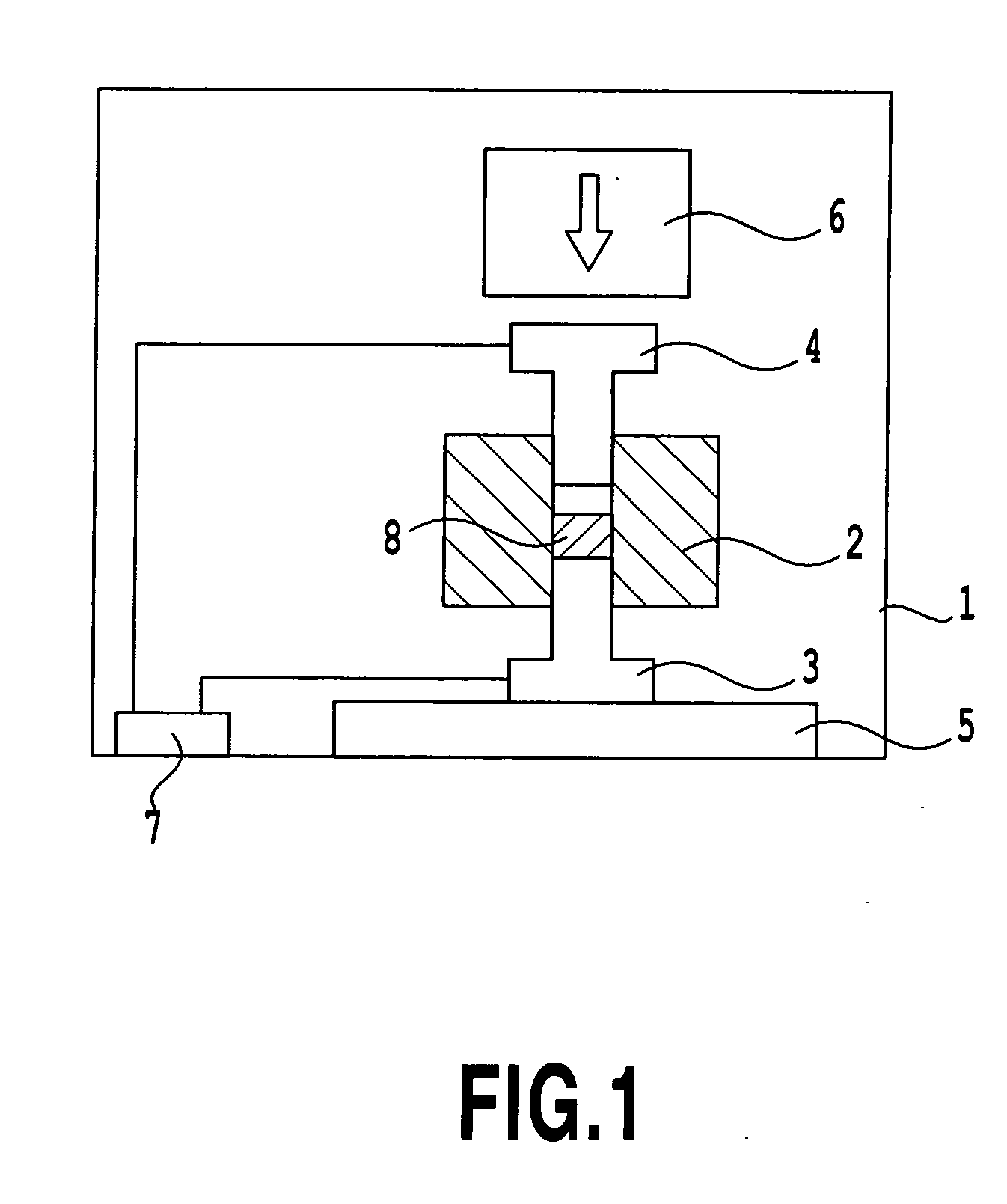

[0055] Next, the metal fiber mixture was filled into the equipment shown in FIG. 1, and a pressure in the equipment is set to 8 Pa. The die having a through hole of 20×20 cm was used in this example. Into the die is fitted the lower punch to form a recess, and the metal fiber mixture was filled into the recess such that carbon fiber was aligned in one direction. Next, the upper punch was placed on the filled metal fiber mixture, and pressure of 25 MPa was applied by using the plunger.

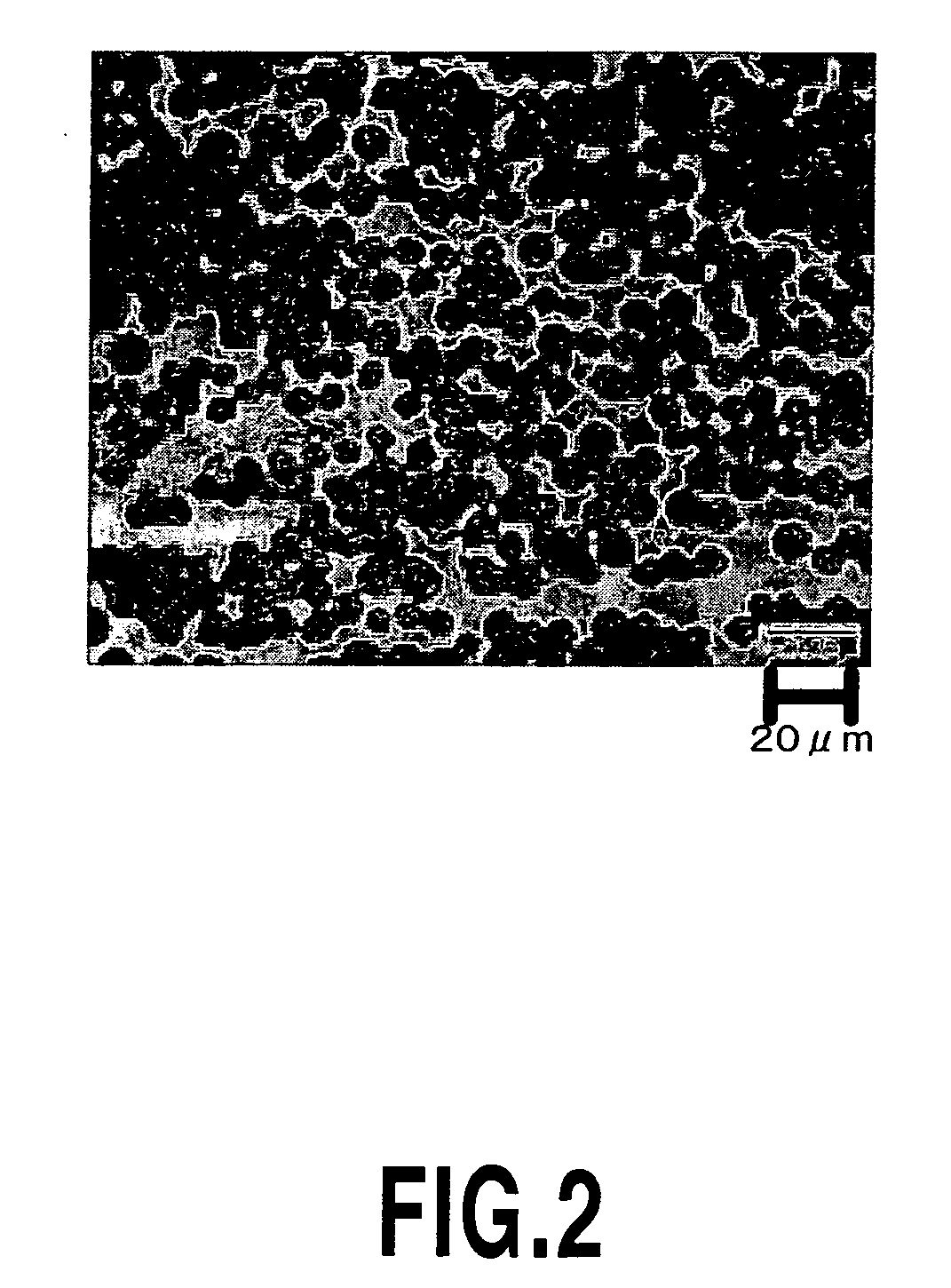

[0056] Then, pulse el...

example 2

[0058] The same procedures as described in Example 1 are repeated, except that the amount of carbon fiber is changed to 4 grams and that of aluminum powder was changed to 4 grams. The obtained metal-based carbon fiber composite material contained 60% of carbon fiber based on a total weight of the composite material and had a density of 1.75 g / cm3. The composite material had an ideal density of 2.38 g / cm3 and a relative density of 73%. The composite material had a thermal conductivity of 300 W / mK, as measured in the aligning direction of the carbon fiber.

example 3

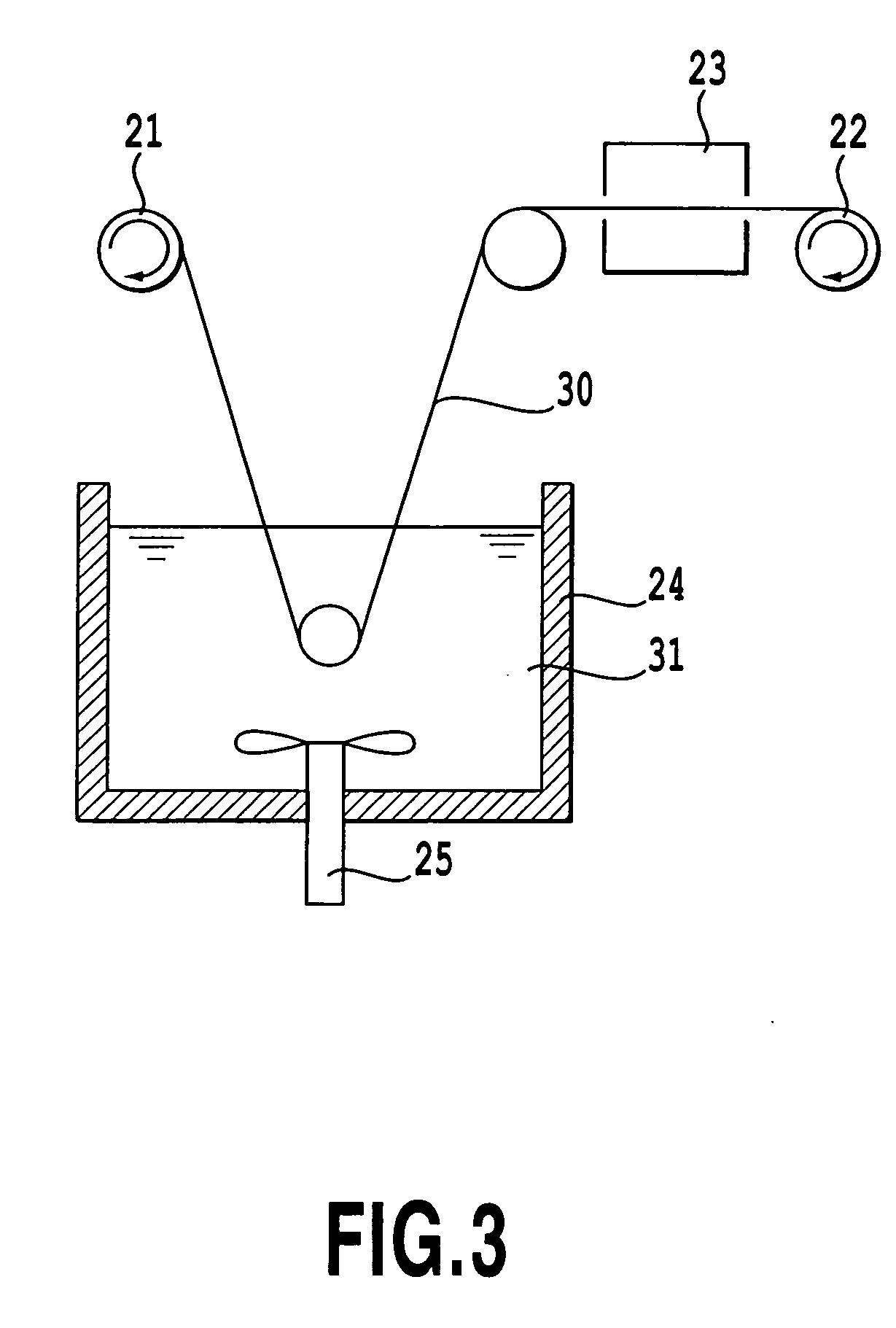

[0059] In this example, a suspension immersion method was used to prepare a metal fiber mixture, in which an aluminum powder suspension was applied to carbon fiber that can be handled as continuous fiber. The metal fiber mixture was sintered in the pulsed electric current sintering method to provide a metal-based carbon fiber composite material.

[0060] Pitch-based carbon fiberhaving a thermal conductivity of 1000 W / mK and a diameter of 10 μm was used as carbon fiber and a bundle made of 6000 pieces of the fiber was wound up around an unwinding bobbin 2. Flake-like powder, which is 1 μm or less in thickness and 30 μm in mean representative length toward a surface (in-plane) direction, was used as aluminum powder. The aluminum powder was mixed in ethanol containing 2% by weight (based on weight of the ethanol) of a dispersant-adhesive (Pluronic (registered trade mark) F68) to form a metal powder suspension. The content of aluminum powder was 30% by weight based on the weight of the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com