Novel nanocomposites and their application as monolith columns

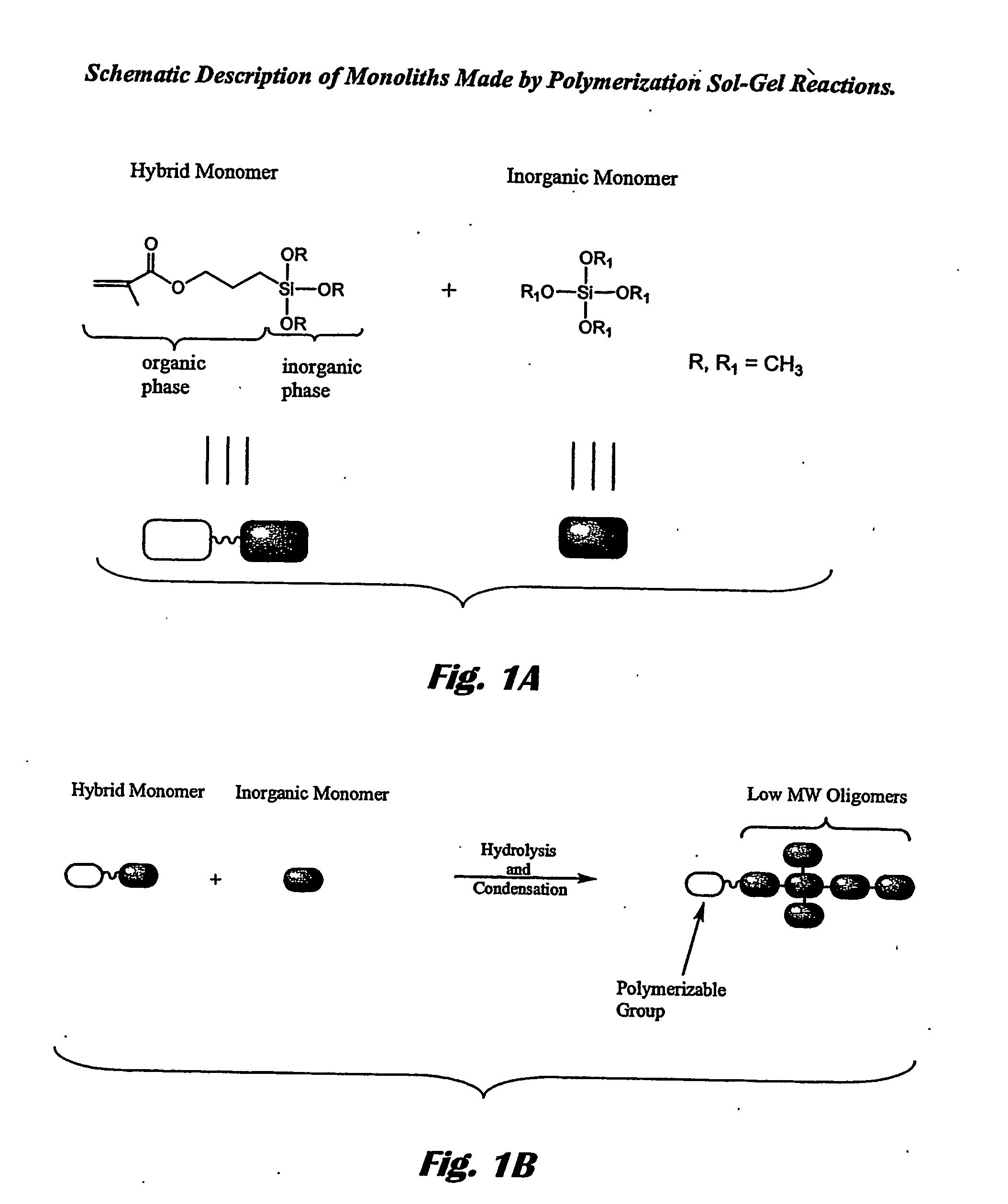

a nanocomposites and monolithic technology, applied in the field of new nanocomposites and their application as monolith columns, can solve the problems of insufficient separation performance, many organic chromatographic materials shrink and swell, and most organic chromatographic materials do not have the mechanical strength of typical chromatographic silicas, etc., to achieve novel physical characteristics, enhance capillary wall adhesion, and increase shrinkage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

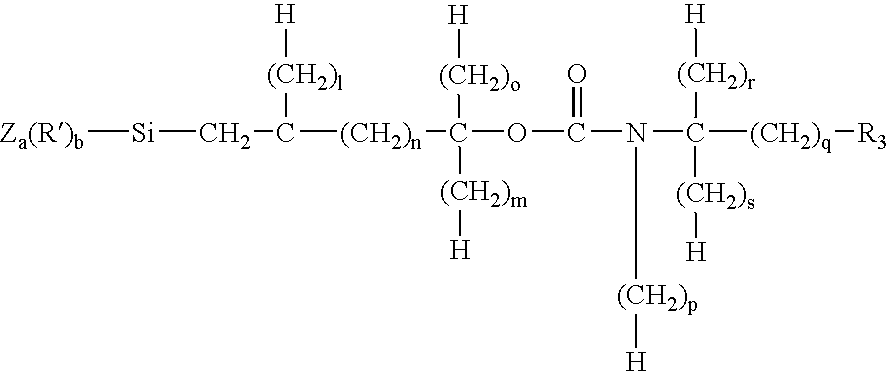

Method used

Image

Examples

example 1

[0164] A Harvard Apparatus Model ‘33’ Dual Syringe Pump(Harvard Apparatus Inc., Hollistion, Mass., or equivalent) and 10 mL Pharmaseal® syringe (American Pharmaseals Laboratory, Glendale, Calif., or equivalent) were used in all capillary filling and purging steps.

[0165] A fused silica capillary column (ca. 2 m in length) was treated by the following five steps: (1) the column was purged with 1N NaOH at a flow rate of 50 μL / min for at least 5 minutes, sealed via compression fittings and heated to 90° C. for 17 hours; (2) the column was purged with 1N HCl water solution at a flow rate of 50 μL / min for at least 5 minutes; (3) the column was rinsed with water, acetone, and then toluene at a flow rate of 50 μL / min for 10 minutes each (total volume ˜500 μL, >10 times column volume); (4) the column was filled with a mixture of 0.5 mL (3-methacryloxypropyl)trimethoxysilane / 0.5 mL pyridine / 10 mL toluene at a flow rate of 50 μL / min for 5 minutes, sealed at both ends of the column and the col...

example 2

[0167] Pluronic® F38 (Example 2a—0.622 g, Example 2b—0.596 g) and urea (Example 2a—0.517 g, Example 2b—0.515 g) were added to 5 mL of a 15 mM acetic acid solution at room temperature in a glass vial. The solutions were deoxygenated by nitrogen gas purging for at least 2 minutes before Vazo® 64 (1-2 mg) was added, and then the solution was cooled to 0° C. In a separate glass vial, a 2 mL silane mixture (4 / 1 TMOS:MAPTMOS v / v) was prepared and then cooled to 0° C. Next, the silane mixture was added slowly to the acetic acid solution. The combined solutions were stirred at 0° C. for 1 h and then at room temperature (rt) for 1.75 h.

[0168] The resulting solutions were delivered into two separate 50 μm (I.D.)×40 mm (L) capillary columns that were surface treated as described in Example 1 with the exception that step (1) was run for 2 hours. The columns were then sealed at both ends with two compression screws and were heated at 45° C. in an oven for 18.5 h.

[0169] Monolith morphology of t...

example 3

[0170] As described in Example 2, Pluronic® F38 and urea were added to 5 mL of an acetic acid solution at room temperature. The solutions were deoxygenated by nitrogen gas purging for at least 2 minutes before Vazo® 64 was added. The stirred solutions were cooled to 0° C. for a specific time, and 2 mL of a 0° C. silane mixture (4 / 1 TMOS:MAPTOS v / v) was added slowly to the acetic acid solution. The combined solutions were stirred at 0° C. for a prescribed time and then at rt for an additional time period.

[0171] The resulting solutions were delivered into separate 150 μm (I.D.)×40 mm (L) capillary columns that had been surface treated as described in Example 1. The columns were then sealed at both ends with two compression screws and were heated at 65° C. for a prescribed time and then at an elevated temperature (Example 3a,b 120° C.; Example 3c-j 105° C.; Example 3k-o 110° C.; Example 3p-t 125° C.) for an additional time period.

[0172] Monolith morphology of the cross-sections of ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

| Adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com