High Efficiency, Wavelength Stabilized Laser Diode Using AWG's And Architecture For Combining Same With Brightness Conservation

a wavelength stabilized, laser diode technology, applied in semiconductor lasers, instruments, optical elements, etc., can solve the problems of simple optical combiners that do not meet the efficiency requirement of fundamental physics, limited power achievable from a single laser module, and relatively high wavelength shift, so as to achieve efficient coupling of optical gain element arrays and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

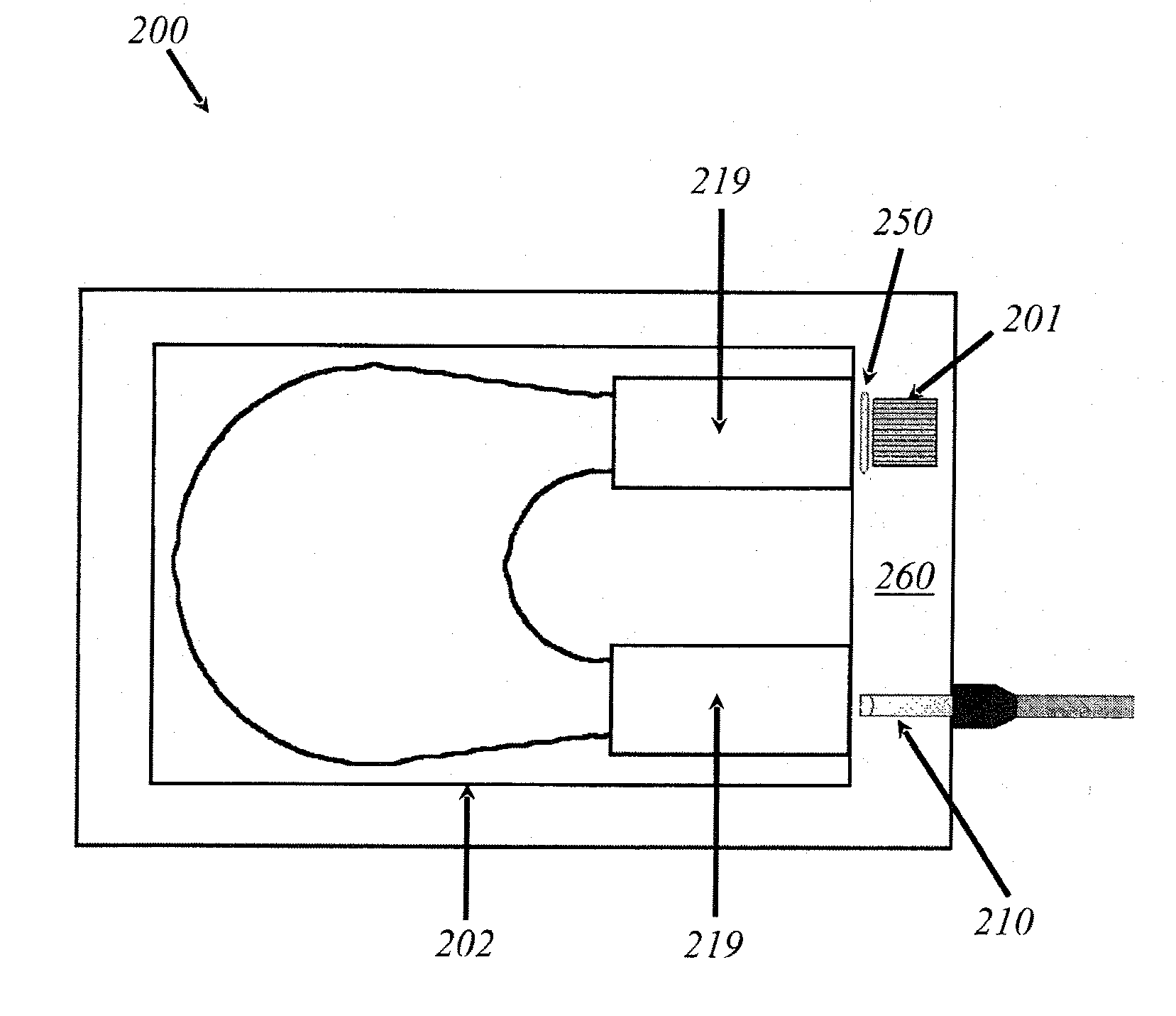

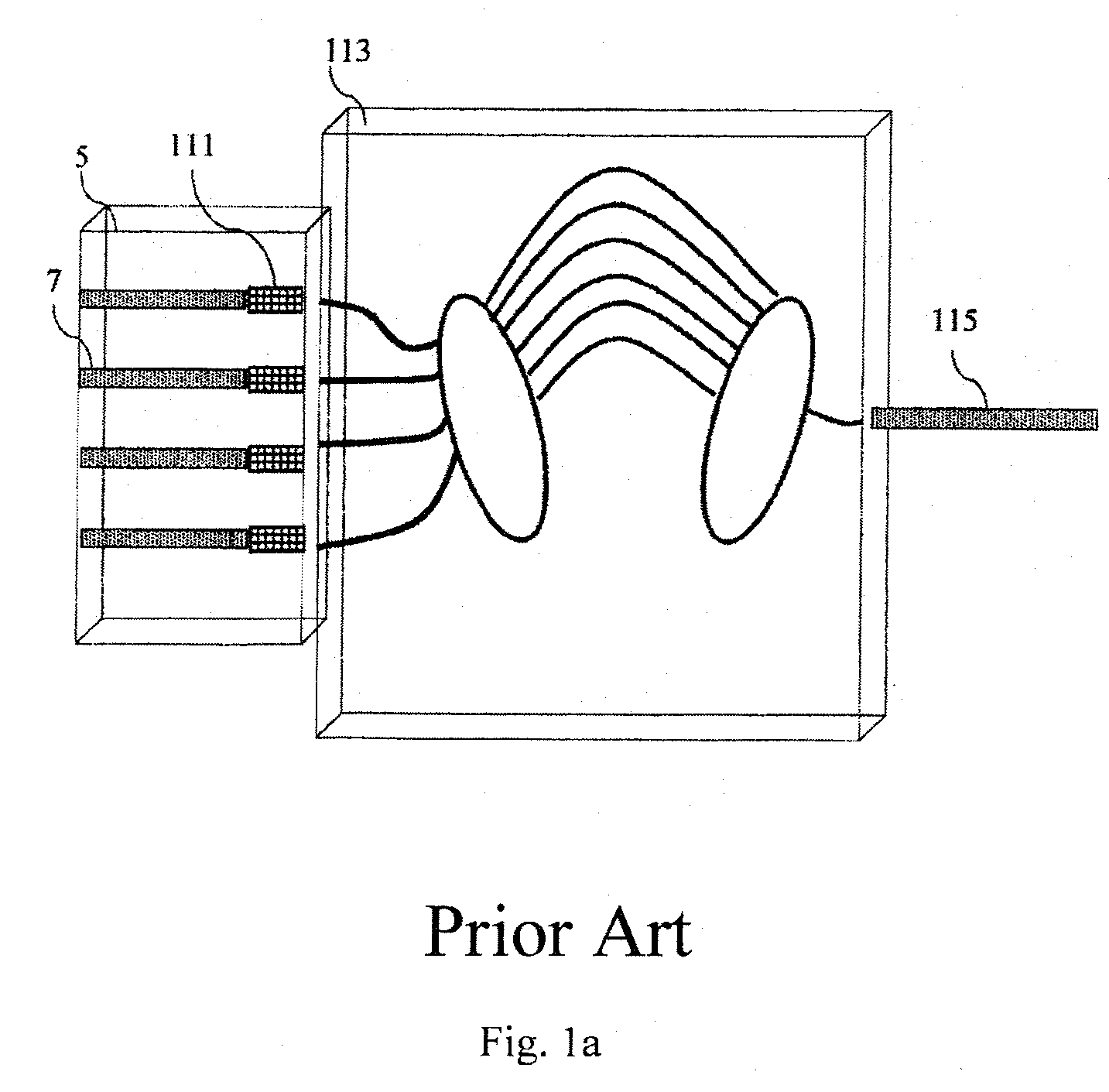

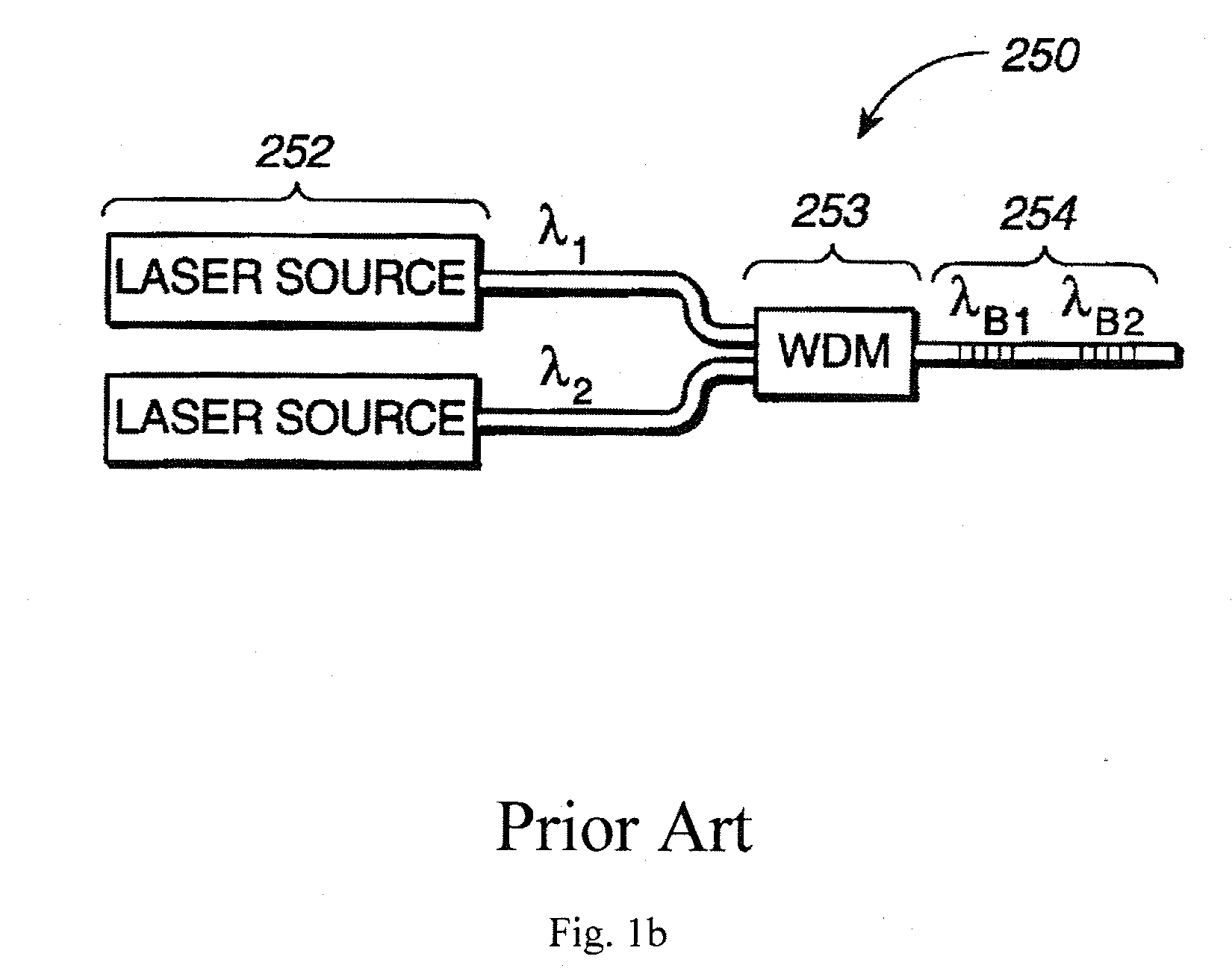

[0061] Silica array waveguide gratings (AWG) form the basis of the design for spectrally multiplexing lasers at narrow channel spacing. The diode-AWG (DAWG) concept has inherent advantages over conventional gratings for spectral combining of laser arrays. Firstly, the AWG has extremely high spectral resolution, enabling a large number of laser diode emitters to be packed into a narrow spectral region. Secondly, due to their planar structure, the AWG is well matched for efficient coupling to a diode bar, and it uniquely enables disruptive laser architectures, such as flares, that can greatly increase the optical power per emitter. Thirdly, the concept is cost-effective, scalable, highly manufacturable, and precisely controllable since it is based on silicon wafer processing technology. Finally, it enables a simple, compact, robust, thermally stable DAWG module with fiber-coupled or free space collimated output with minimum amount of micro-optics.

[0062] This invention disclosure pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com