Fabrication of vertical sidewalls on (110) silicon substrates for use in si/sige photodetectors

a technology of silicon substrate and silicon substrate, applied in the field of near-infrared photodetectors, can solve the problems of small critical thickness, high dark current, and inevitable lattice defects in sige, and achieve the effect of improving the quantum efficiency of photodetectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

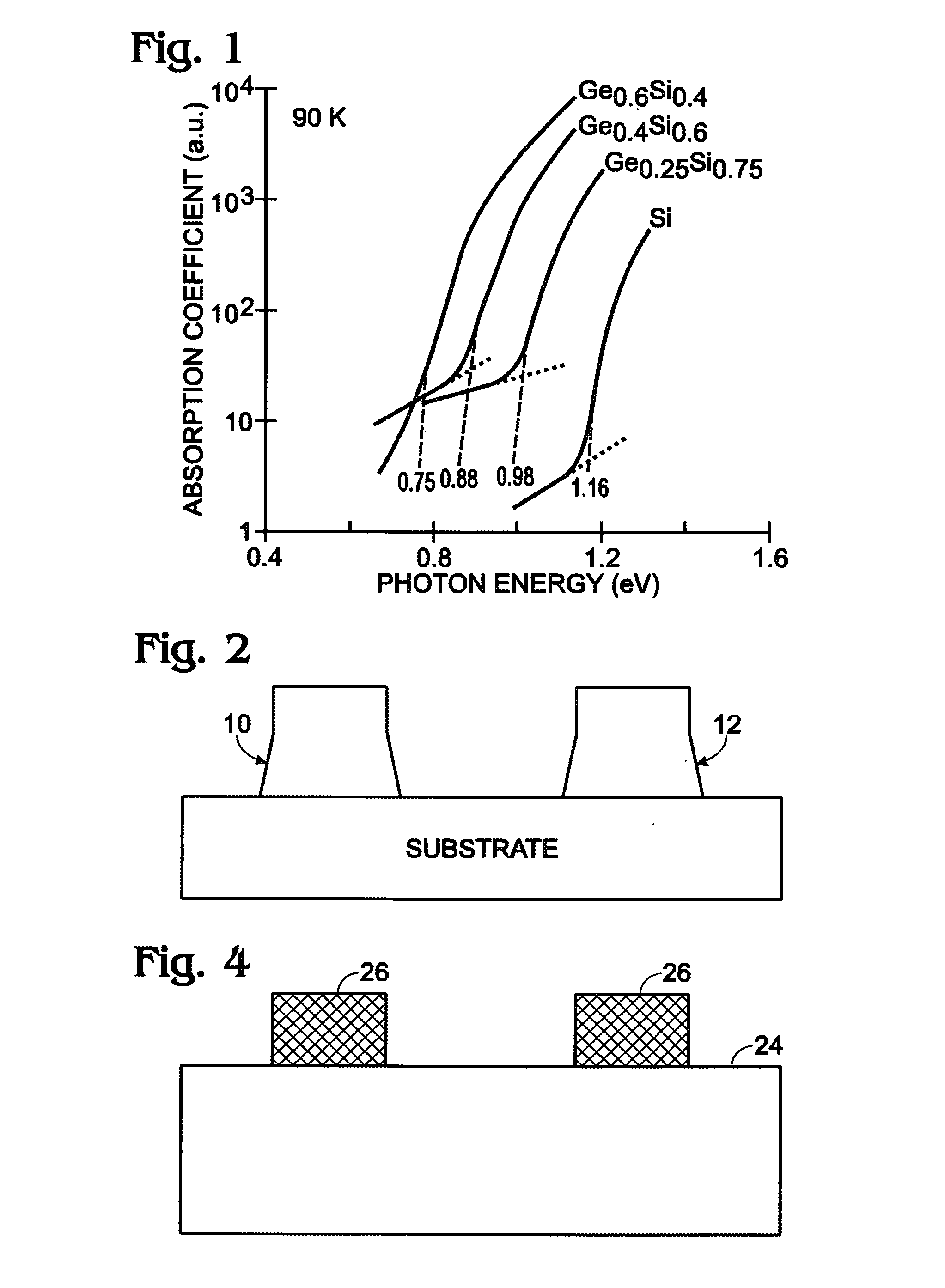

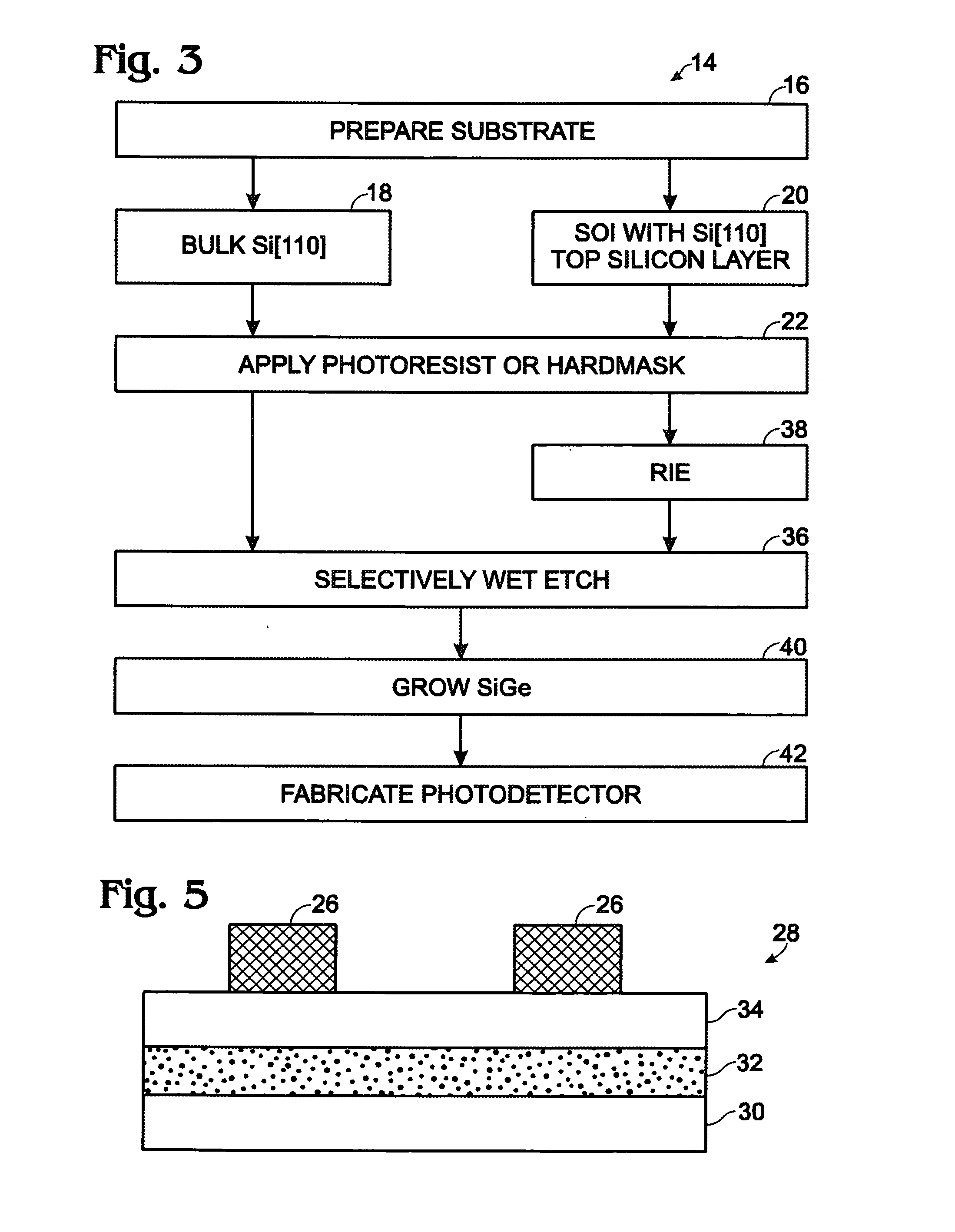

[0026] The objective of this invention is to improve the quantum efficiency of photodetectors, e.g., near-IR photodetectors, integrated on silicon substrates. This is done by providing silicon structures with nearly vertical sidewalls and low crystalline defects to enable the growth of low-defect strained, epitaxial SiGe and / or SiGe / Si multilayers on the sidewalls. By so doing, the optical path length for absorption of light is be determined by the height of the sidewalls, and not by the SiGe film thickness. In this way the quantum efficiency of the photodetector is improved.

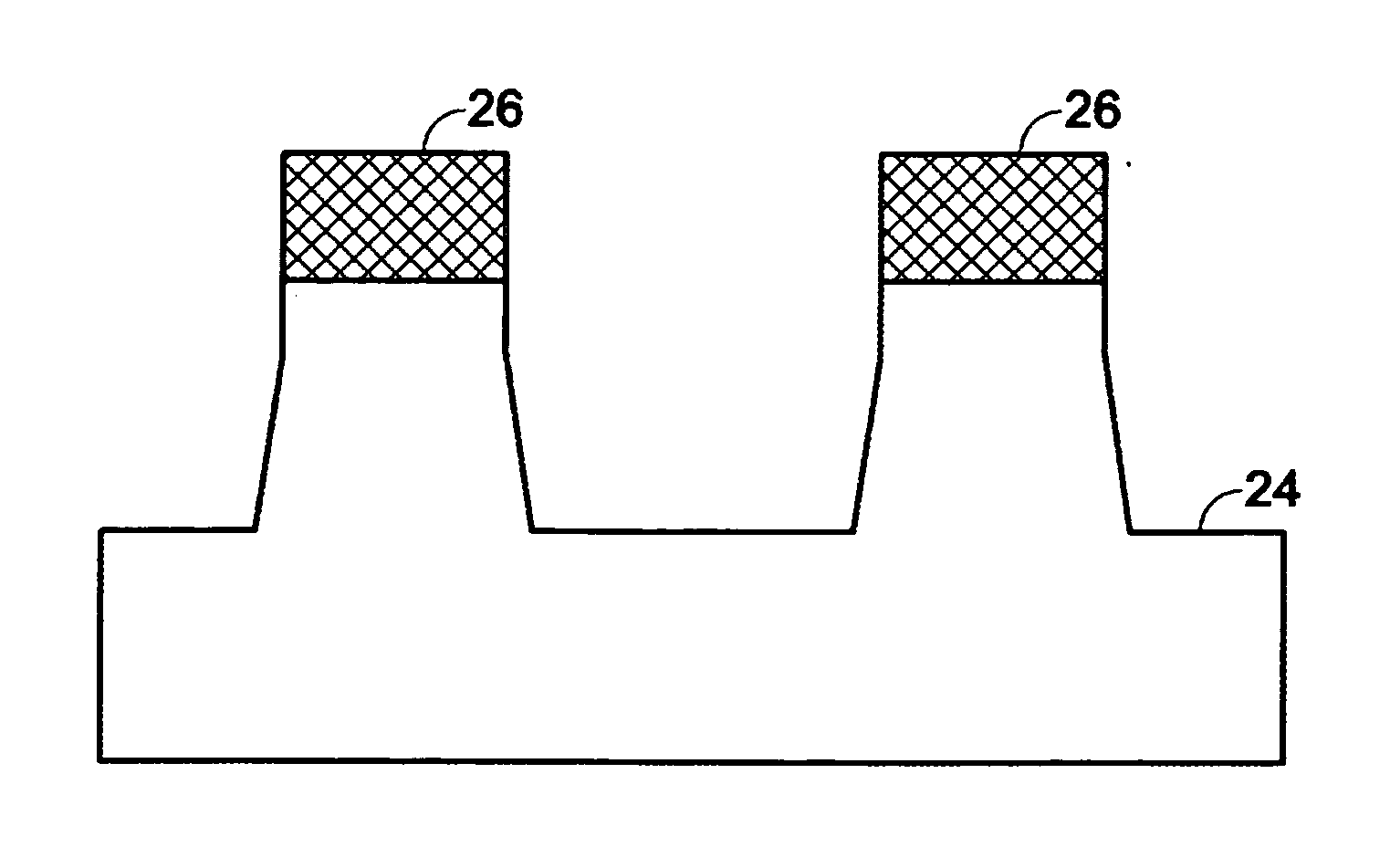

[0027] As previously noted, the use of reactive ion-etching (RIE) to etch silicon structures results in rough, damaged sidewalls with unacceptably large slopes. The readily available selective etch processes do not improve this situation on silicon (001) substrates. The present invention uses silicon (110) substrates and selective chemical etching to fabricate vertical sidewalls on which to grow strained SiGe a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com