Ceramic Honeycomb Filter, Exhaust Gas-Cleaning Apparatus, and Exhaust Gas-Cleaning Method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1-5

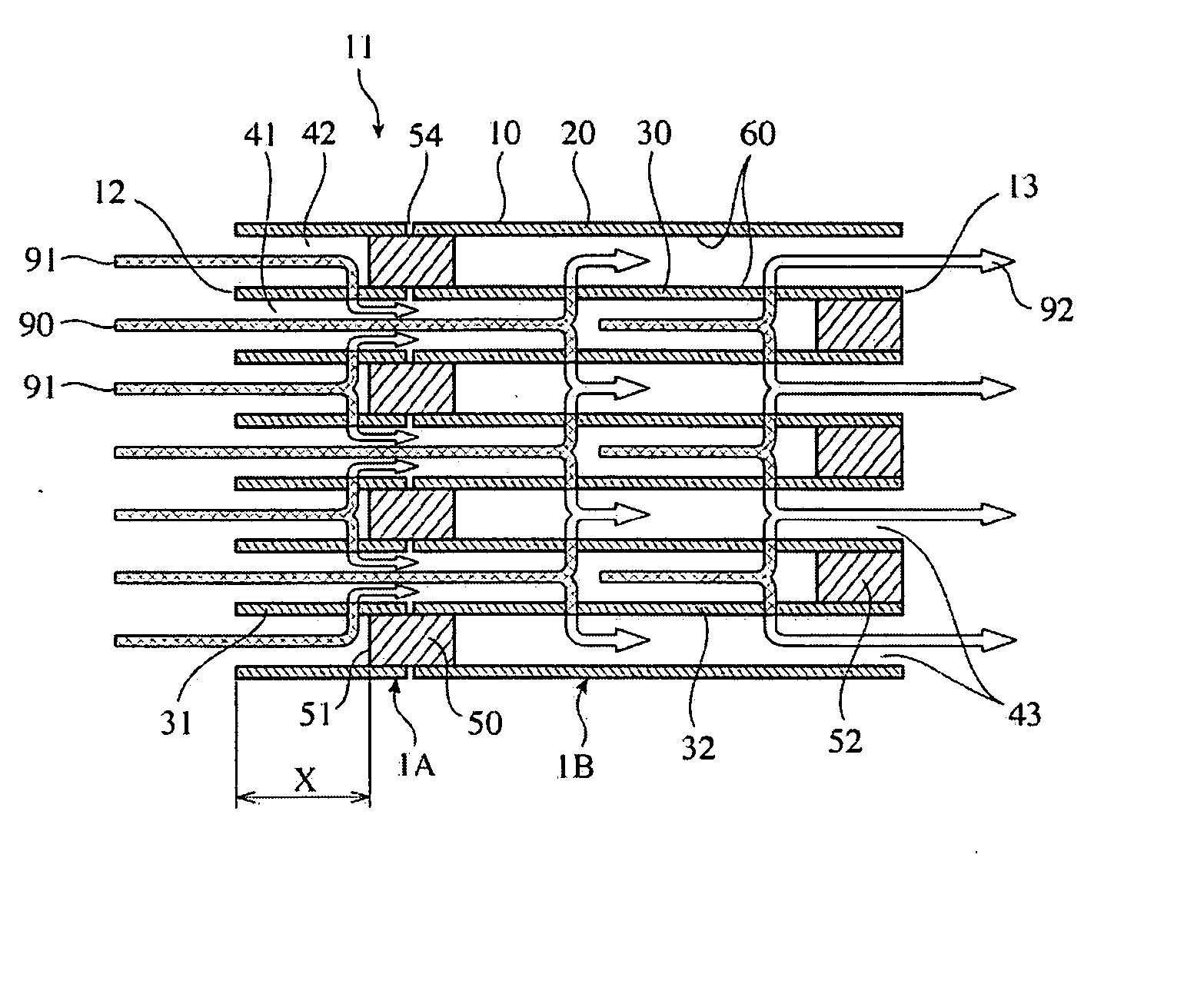

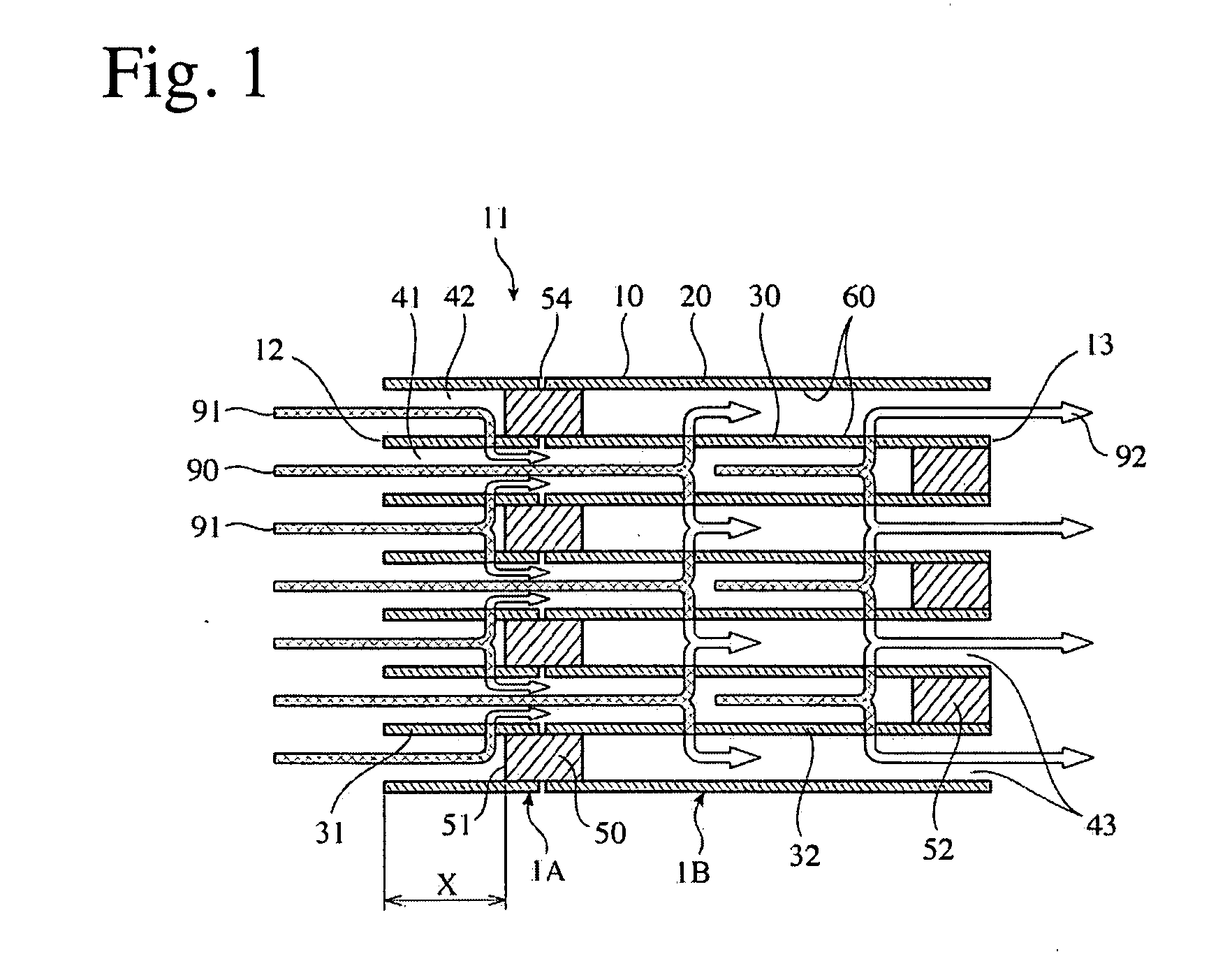

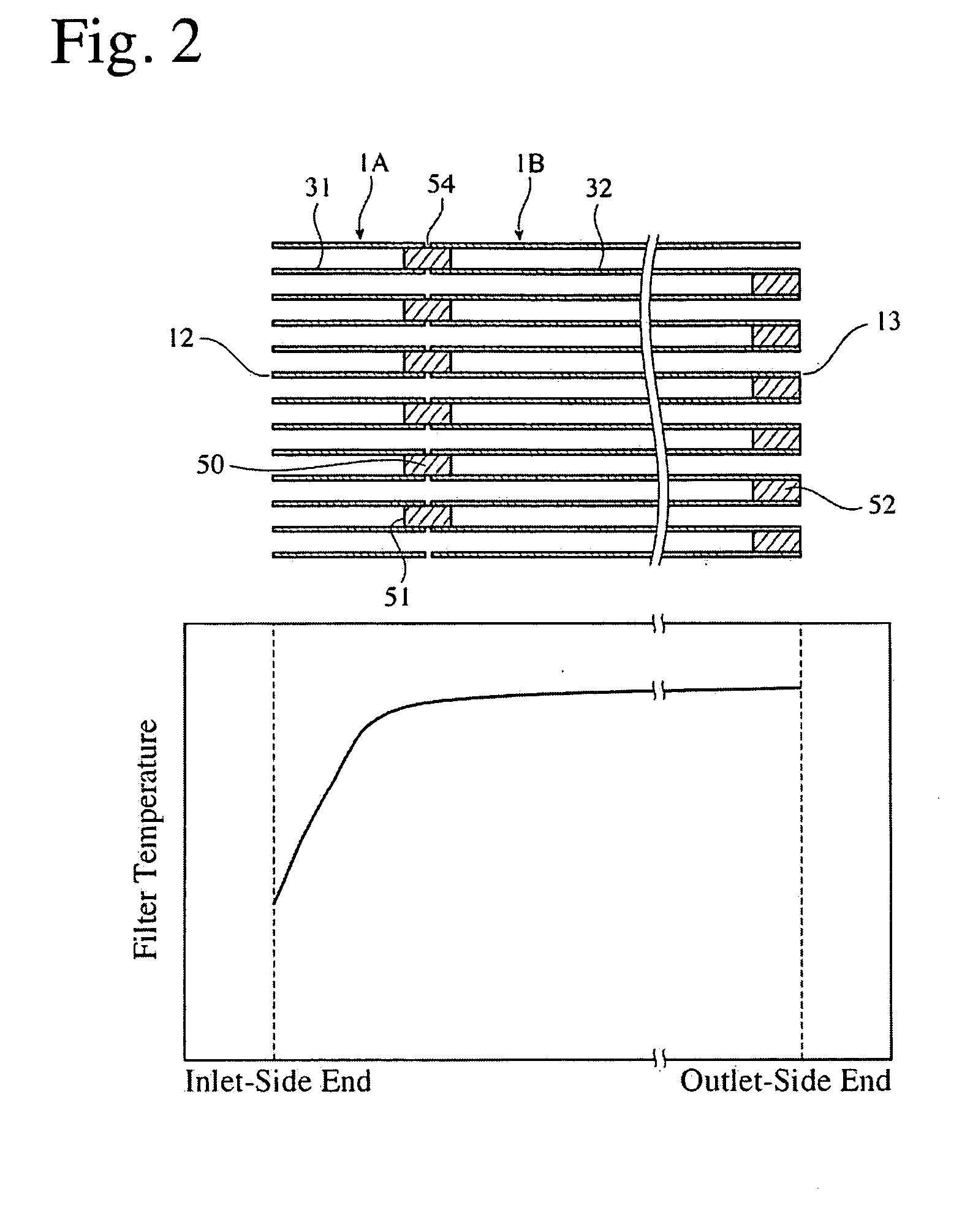

[0076] The powder composition of kaolin, talc, silica, aluminum hydroxide, alumina, etc. was prepared to obtain a cordierite-forming powder comprising, on a mass basis, 47-53% of SiO2, 32-38% of Al2O3, 12-16% of MgO, and 2.5% or less in total of inevitable components (CaO, Na2O, K2O, TiO2, Fe2O3, PbO, P2O5, etc.), and fully mixed with a molding aid, a pore-forming agent, and a predetermined amount of water to prepare a material extrusion-moldable to a honeycomb structure. It was then extrusion-molded by a known extrusion die to produce a honeycomb structure molding comprising a peripheral wall 20, and cell walls 30 inside this peripheral wall 20 for defining flow paths each having a square cross section, which was then dried and sintered to obtain a honeycomb structure 1A with exhaust-gas-inlet-side cell walls 31 and a honeycomb structure 1B with exhaust-gas-outlet-side cell walls 32. Each honeycomb structure had a diameter of 267 mm with 0.3-mm-thick cell walls (porosity: 65%, pitc...

example 6

[0087] A honeycomb structure 1A having a diameter of 267 mm and a total length of 96.4 mm, whose cell walls had a pitch of 1.5 mm, a thickness of 0.3 mm and a porosity of 65%, and a honeycomb structure 1B having a diameter of 267 mm and a total length of 208.3 mm, whose cell walls had a pitch of 1.5 mm, a thickness of 0.3 mm and a porosity of 65%, were produced in the same manner as in Example 2. With a slurry containing a plastic plugging material introduced into the end portions of the flow paths of the honeycomb structures 1A and 1B in a checkerboard pattern, the honeycomb structures 1A and 1B were integrally connected such that a 0.1-mm-wide gap 54 was provided between the cell walls of the honeycomb structures 1A and 1B.

[0088] A resin film was attached to the other end 13 of the honeycomb structure 1B, and provided with apertures alternately with the inlet-side plugs 50. A plugging material slurry was introduced into part of the flow paths of the honeycomb structure and solidi...

example 7

[0090] A honeycomb structure 1A having a diameter of 267 mm and a total length of 96.9 mm, whose cell walls had a pitch of 1.5 mm, a thickness of 0.3 mm and a porosity of 65%, and a honeycomb structure 1B having a diameter of 267 mm and a total length of 206.9 mm, whose cell walls had a pitch of 1.5 mm, a thickness of 0.3 mm and a porosity of 65%, were produced in the same manner as in Example 2. These honeycomb structures were integrally connected by plugs 50 with a 1-mm gap 54, and plugs 52 were formed at the other end 13 of the honeycomb structure 1B alternately with the plugs 50.

[0091] Pt, cerium oxide and active alumina (catalyst B) were carried by the honeycomb structure 1A and the plugs 50, such that the amounts of cerium oxide and active alumina carried were the same as in the catalyst A, and that the amount of Pt carried was 4 g / L. Pt, cerium oxide and active alumina (catalyst C) were carried by the honeycomb structure 1B and the plugs 52, such that the amounts of cerium o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

| Digital information | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com