Hot-and cold-formed aluminum alloy

a technology of aluminum alloy and hot-and-cold-formed alloy, which is applied in the direction of heat treatment equipment, manufacturing tools, furnaces, etc., can solve the problems of low dynamic strength, high cost of corrosion protection, and alloys that cannot reach adequate strength levels, so as to achieve the effect of high strength and corrosion resistance of the components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0028] An alloy melt having the composition in percent by weight:

silicon1.2,magnesium1.0,manganese0.5,copper0.05,iron0.2,chromium0.2,titanium0.05,zinc0.1,circonium0.2,

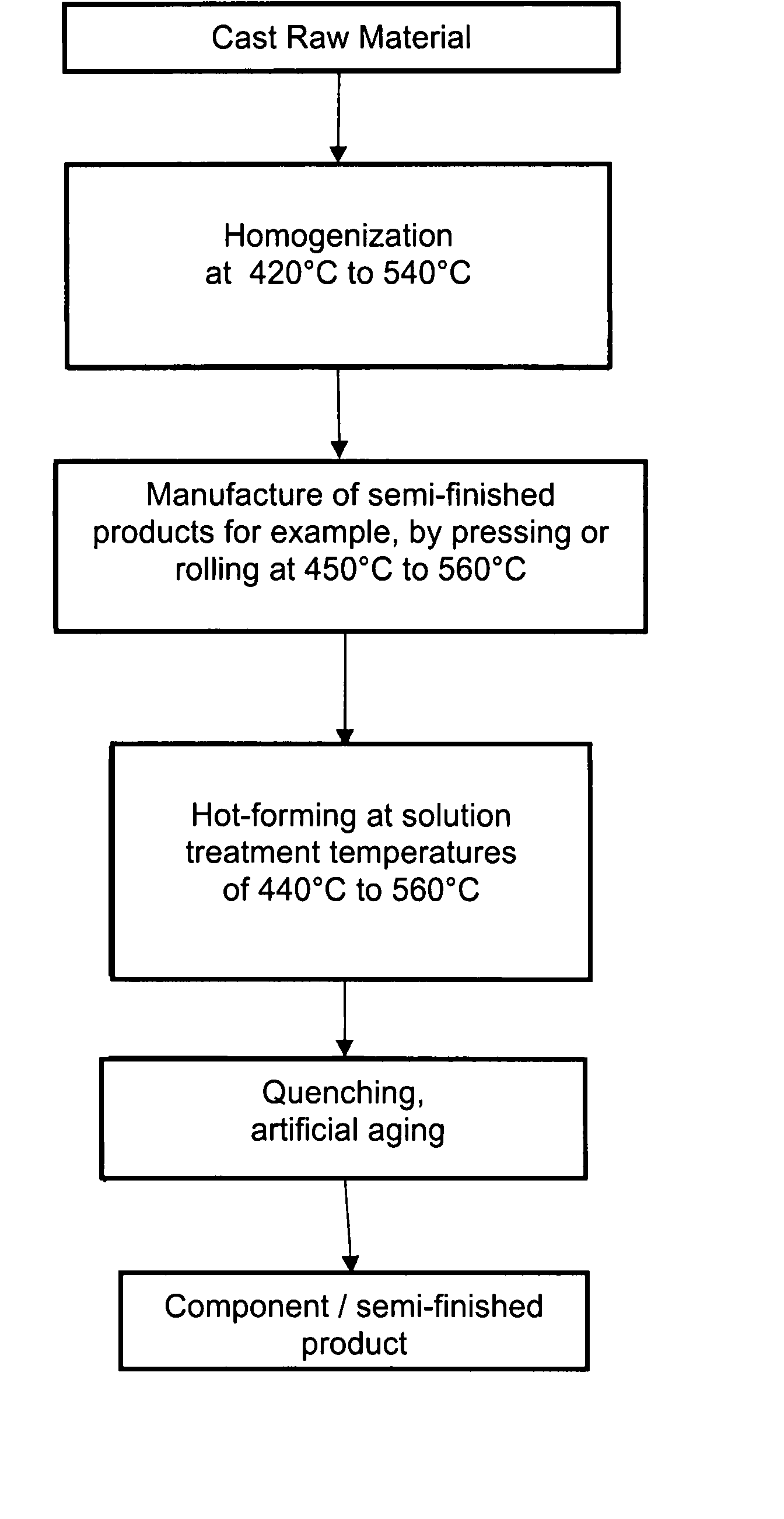

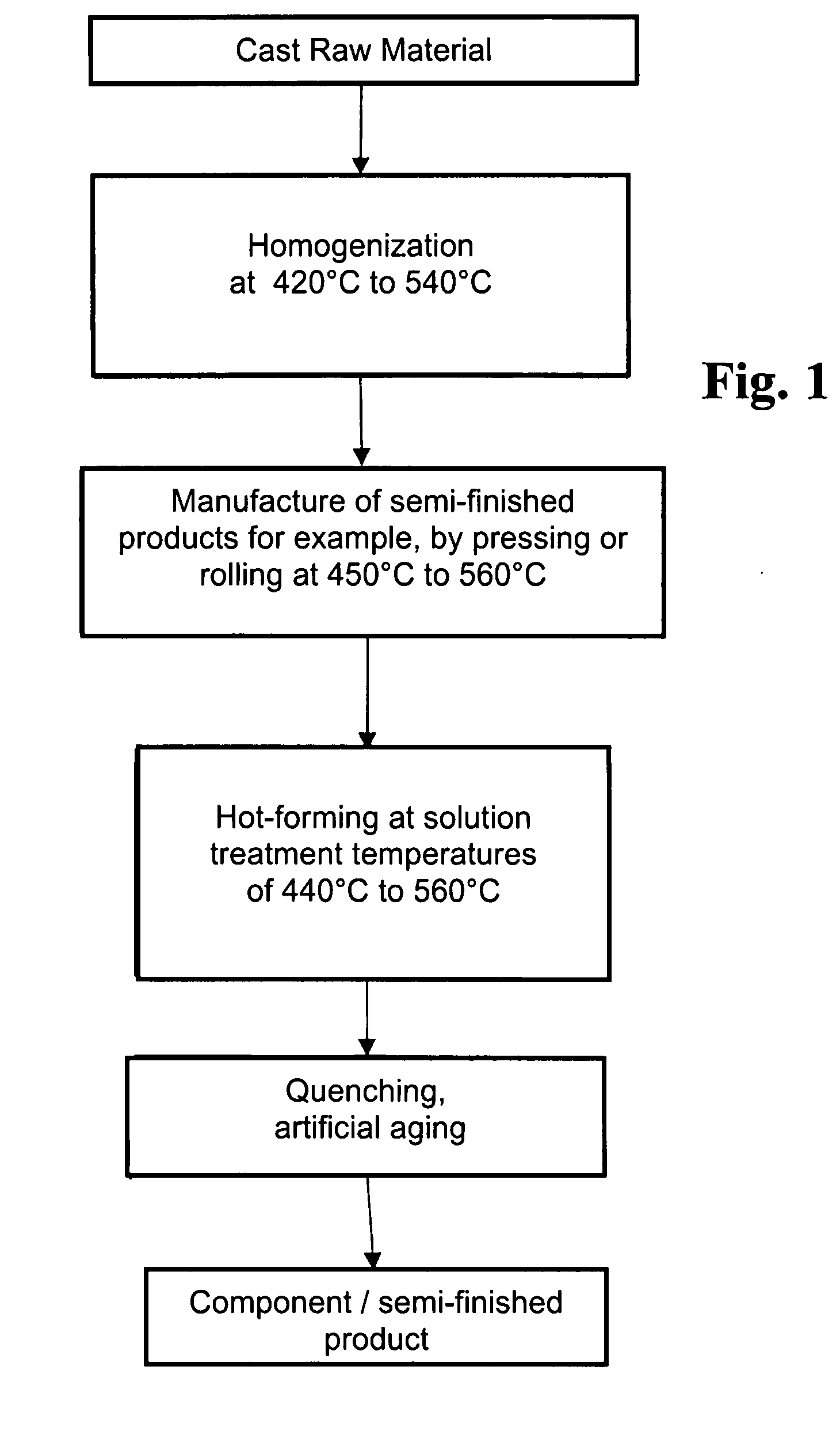

is cast in ingots. The ingots are homogenized at a temperature of 480° C. for 12 hrs. In the next process step, the ingots are pressed into round rods (=semi−finished product) at a temperature of 500° C. The round rods are quenched and cut apart into workpieces having a length of about 20 cm.

[0029] The workpieces are heated to a temperature of 530° C. and formed into tension rods in several forging operations (=forming process). During forging, the workpiece temperature does not fall below 440° C. The tension rods are quenched in water and artificially aged at 200° C. for 4 hrs. The tension rods have a tensile strength of more than 400 MPa and an elongation at break (A5) of more than 13% both in the region of a central rod and in the region of a large eye which usually has a high degree of recrystallization due to ...

example 2

[0030] Analogously to Example 1, cast ingots are homogenized and subsequently rolled into sheets (=semi−finished product) at a temperature of 500° C. Round workpieces are punched out from the sheets and formed into wheels in several steps.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com