Tagetes erecta MARIGOLDS WITH ALTERED CAROTENOID COMPOSITIONS AND RATIOS

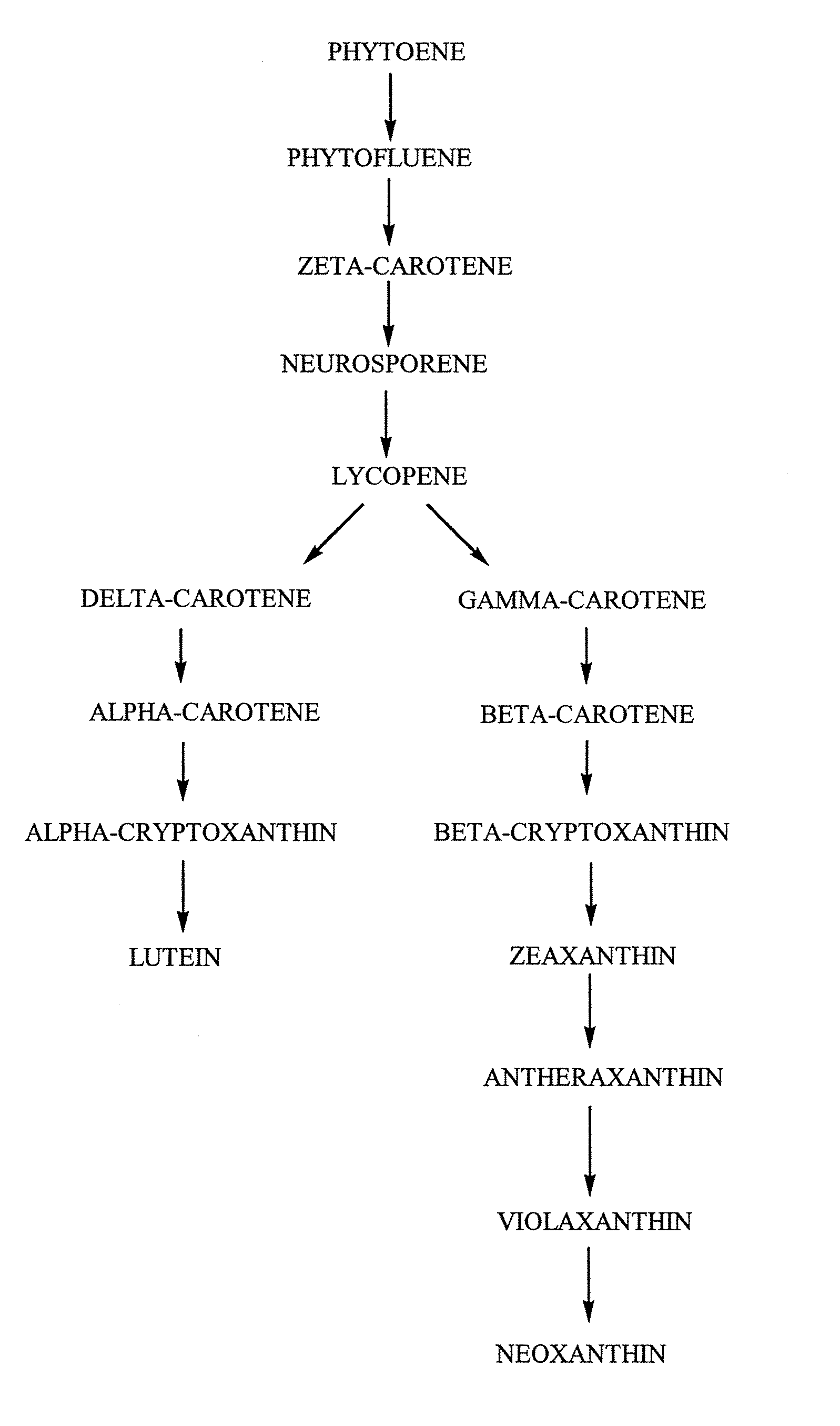

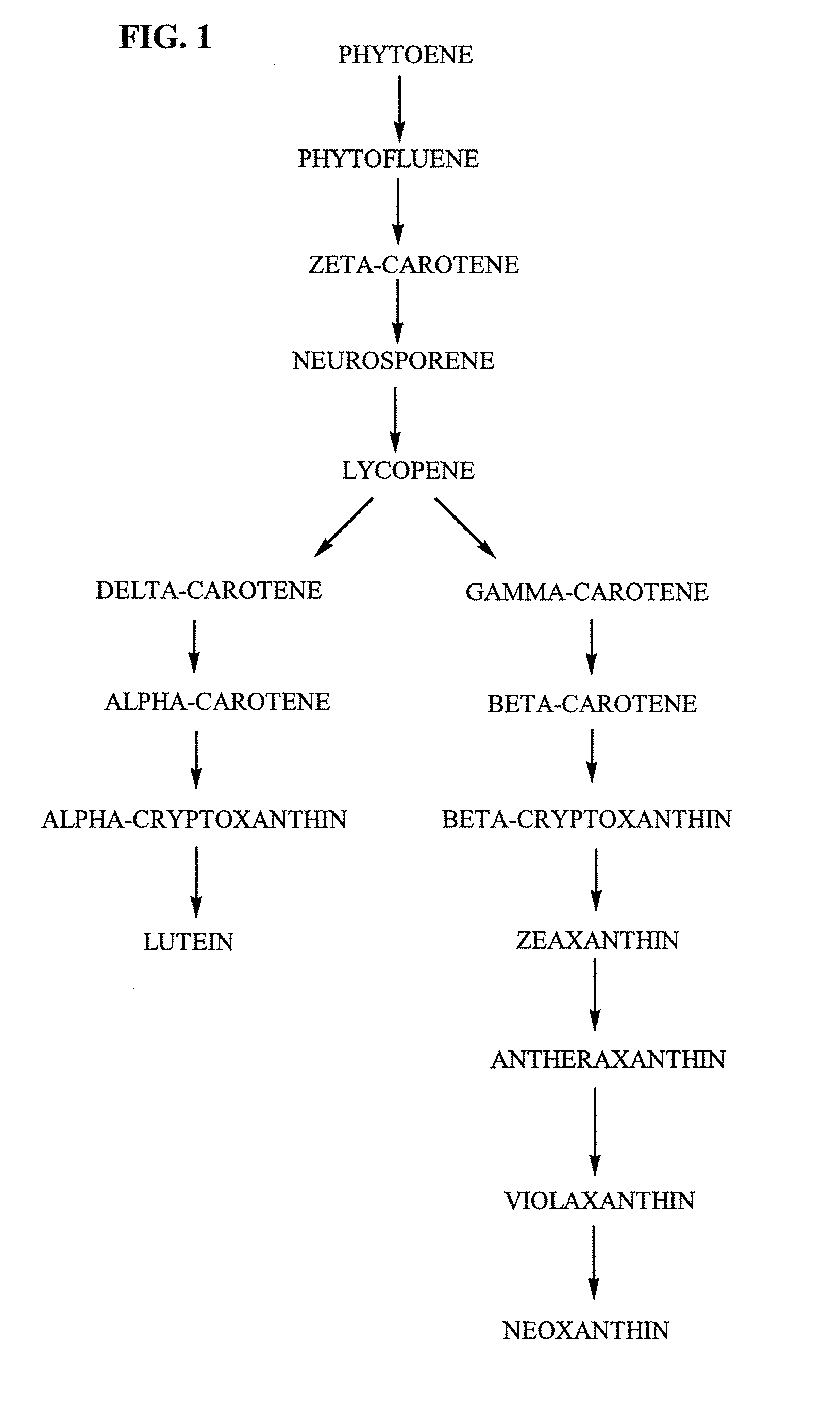

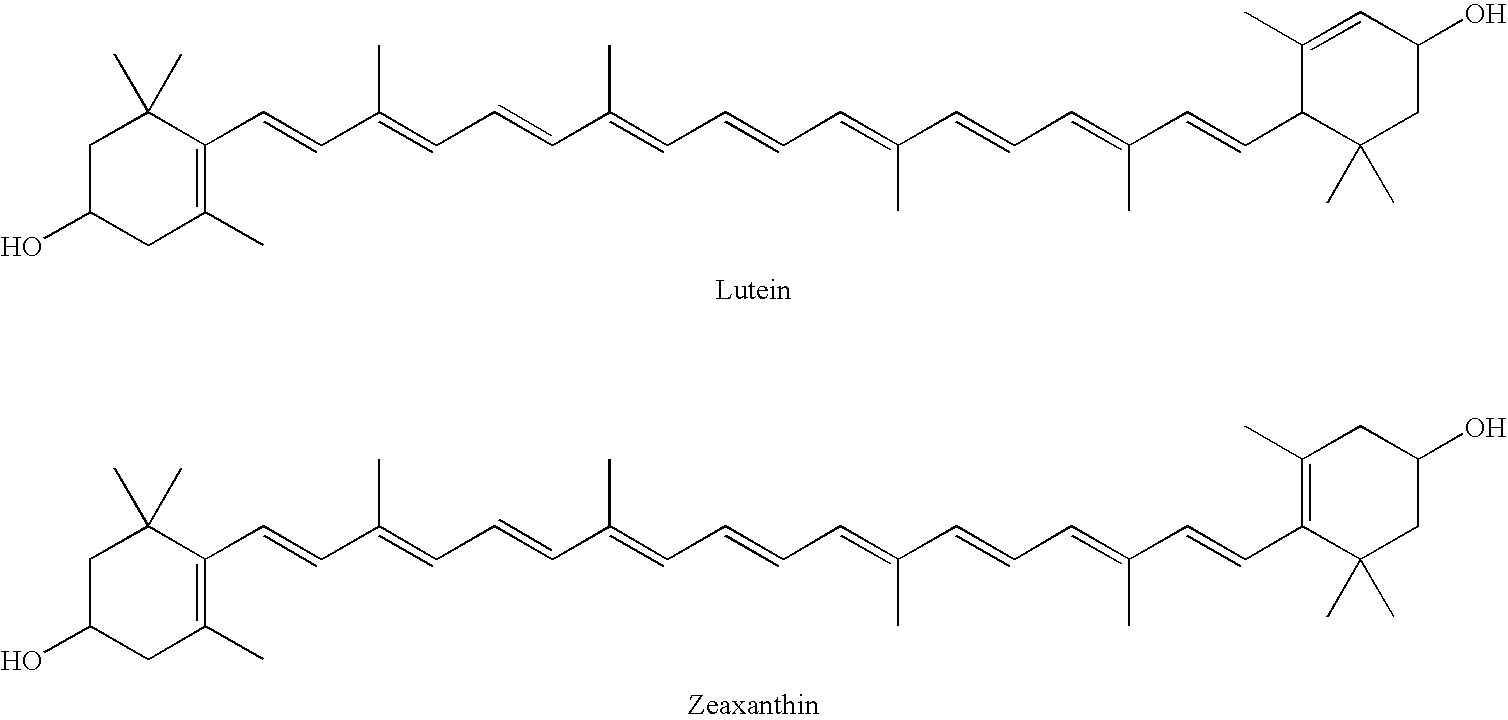

a technology of carotenoid composition and ratio, applied in the field of marigold plant, can solve the problems of low yield, inability to accept by-products, and costly extraction methods, and achieve the effects of enhancing -carotene ratio, enhancing zeaxanthin ratio, and enhancing neoxanthin plus violaxanthin ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

EMS Treatment of Tagetes erecta ‘Scarletade’

[0115]Seeds of Tagetes erecta xanthophyll marigold denominated ‘Scarletade’ (commercially available from PanAmerican Seed Co. 622 Town Road, West Chicago, Ill. 60185) were treated with ethyl methanesulfonate (EMS, commercially available from Sigma Chemical Co., St. Louis, Mo. 63178). Approximately 2,500 seeds were added to 400 ml of 0.4% (v / v) or 0.8% (v / v) EMS and were stirred gently for eight hours at ambient temperature. During a four-hour period following the EMS treatment, the seeds were washed sixteen times, each wash using continuous stirring with 400 ml distilled water. The treated seeds, identified as M1 seeds, were then sown in trays containing soilless potting mix.

[0116]After several weeks, the seedlings were transplanted into pots containing soilless potting mix and maintained in the greenhouse. Flowers produced by those plants were naturally self-pollinated. The resulting seeds, identified as M2 seeds, were harvested from appr...

example 2

HPLC Screening of EMS-Treated Tagetes erecta ‘Scarletade’

[0117]EMS-treated ‘Scarletade’ plants were field-grown at PanAmerican Seed Co. in Santa Paula, Calif. 93060, and were screened by HPLC for altered zeaxanthin ratio. Flowers approximately 98% fully opened were selected for analysis. From each flower, one petal was removed one-third of the distance from the flower center and placed in a 3.5″×0.75″ glass vial containing approximately 5 grams of glass beads. Vials were packaged with dry ice until stored at −80° C.

[0118]For analysis, solvent delivery and aliquot removal were accomplished with a robotic system comprising a single injector valve Gilson 232XL and a 402 2S1V diluter [Gilson, Inc. USA, 3000 W. Beltline Highway, Middleton, Wis.]. For saponification, 3 ml of 50% potassium hydroxide hydro-ethanolic solution (4 water:1 ethanol) was added to each vial, followed by the addition of 3 ml of octanol. The saponification treatment was conducted at room temperature with vials maint...

example 3

EMS Treatment of Tagetes erecta 13819

[0125]Seeds of Tagetes erecta xanthophyll marigold named 13819 (a proprietary breeding selection of PanAmerican Seed Co. 622 Town Road, West Chicago, Ill. 60185) were treated with ethyl methanesulfonate (EMS, commercially available from Sigma Chemical Co. St. Louis, Mo. 63178). Approximately, 7,000 seeds were added to 600 ml of 0.2% (v / v) or 0.4% (v / v) EMS and stirred gently for eight hours at ambient temperature. During a four-hour period following the EMS treatment, the seeds were washed sixteen times, each wash using continuous stirring with 600 ml distilled water.

[0126]The treated seeds, identified as M1 seeds, were then sown in trays containing soilless potting mix. After three to four weeks, the seedlings were transplanted into the field. Flowers produced by these plants were bagged to prevent cross-pollination, and were permitted to spontaneously self-pollinate. The resulting seeds, identified as M2 seeds, were harvested from approximately...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com