Process to obtain biolubricants and bioparaffins by hydroprocessing mixtures of wax obtained from renewable resources and waxes of mineral origin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

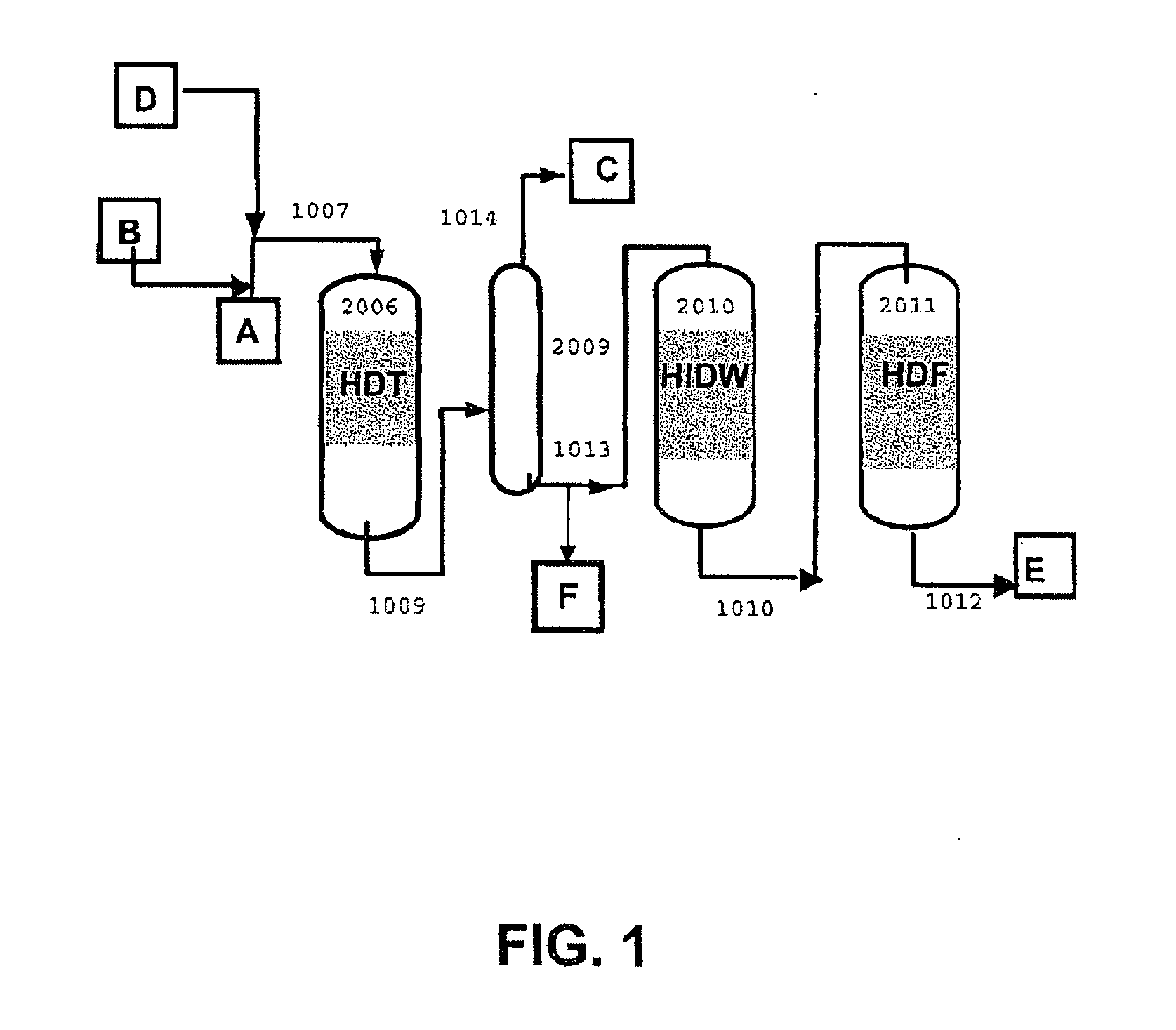

[0029]A characteristic of this invention refers to the nature of the paraffin load used which is from waxes obtained from renewable sources, mixed with mineral waxes.

[0030]The wax load obtained from a renewable source is submitted to successive treatments over different types of catalysts, each destined to perform a specific function in each stage of the process.

[0031]In a broad sense, the process of the invention for hydroconversion of a mixture of loads of waxes from renewable sources treated together with a load of mineral waxes includes the following procedures and operational conditions:[0032]a) hydrotreatment of a stream made up of a mixture in a proportion in mass of waxes obtained from renewable sources of between 1% and 100% and mineral waxes of between 99% and 0% wt / wt. This stream is hydrotreated in a hydrotreatment reactor, under the usual conditions of hydrotreatment which involve an operating pressure within a range of between 7 MPa and 15 MPa, temperature of the catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com