Batten Mounting Water Management System

a water management system and batten technology, applied in the field of building construction, can solve the problems of accelerated corrosion of metal fasteners, moisture damage to internal linings or external cladding materials, rotting of framing members, etc., and achieve the effect of facilitating drainage and ventilation of cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

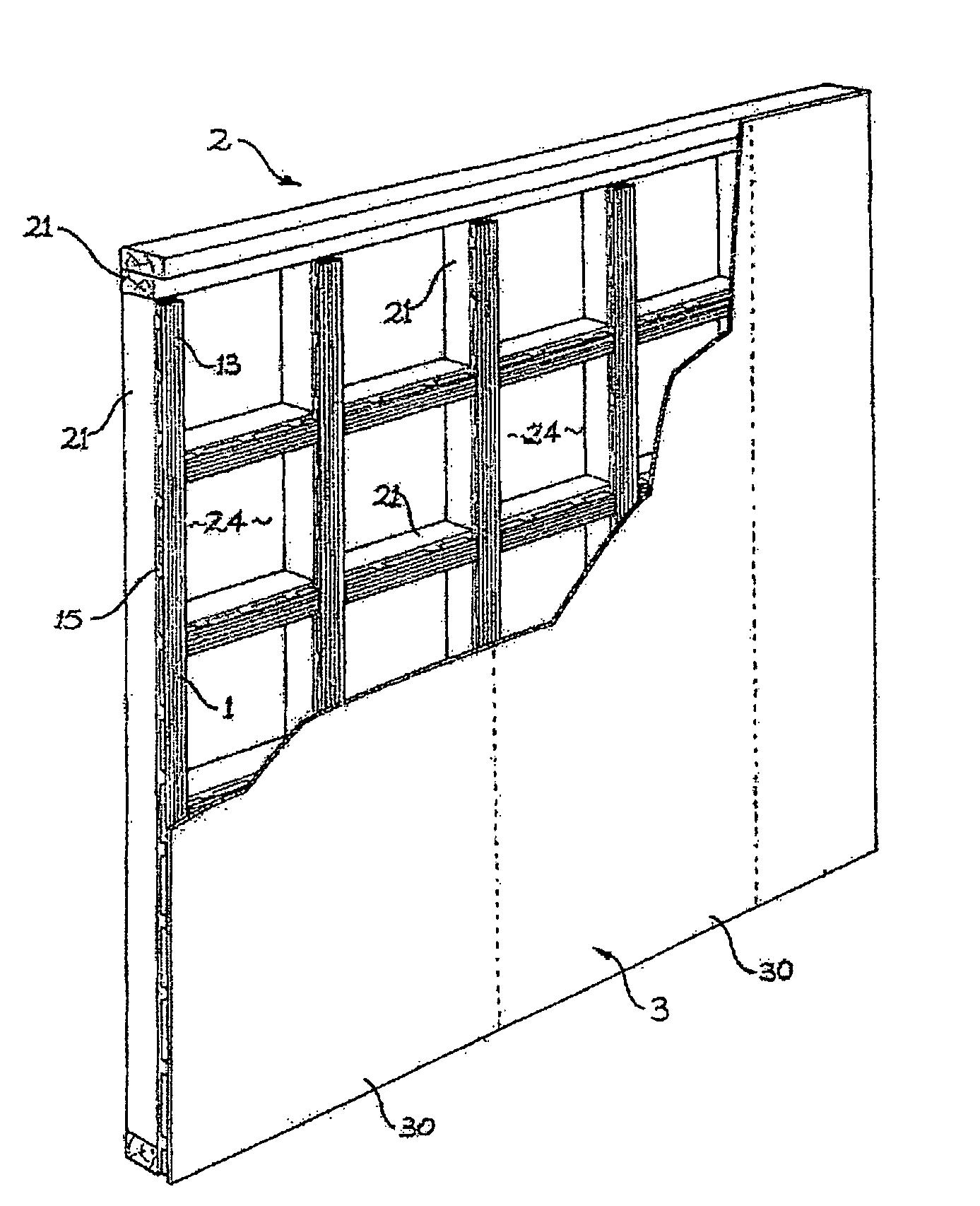

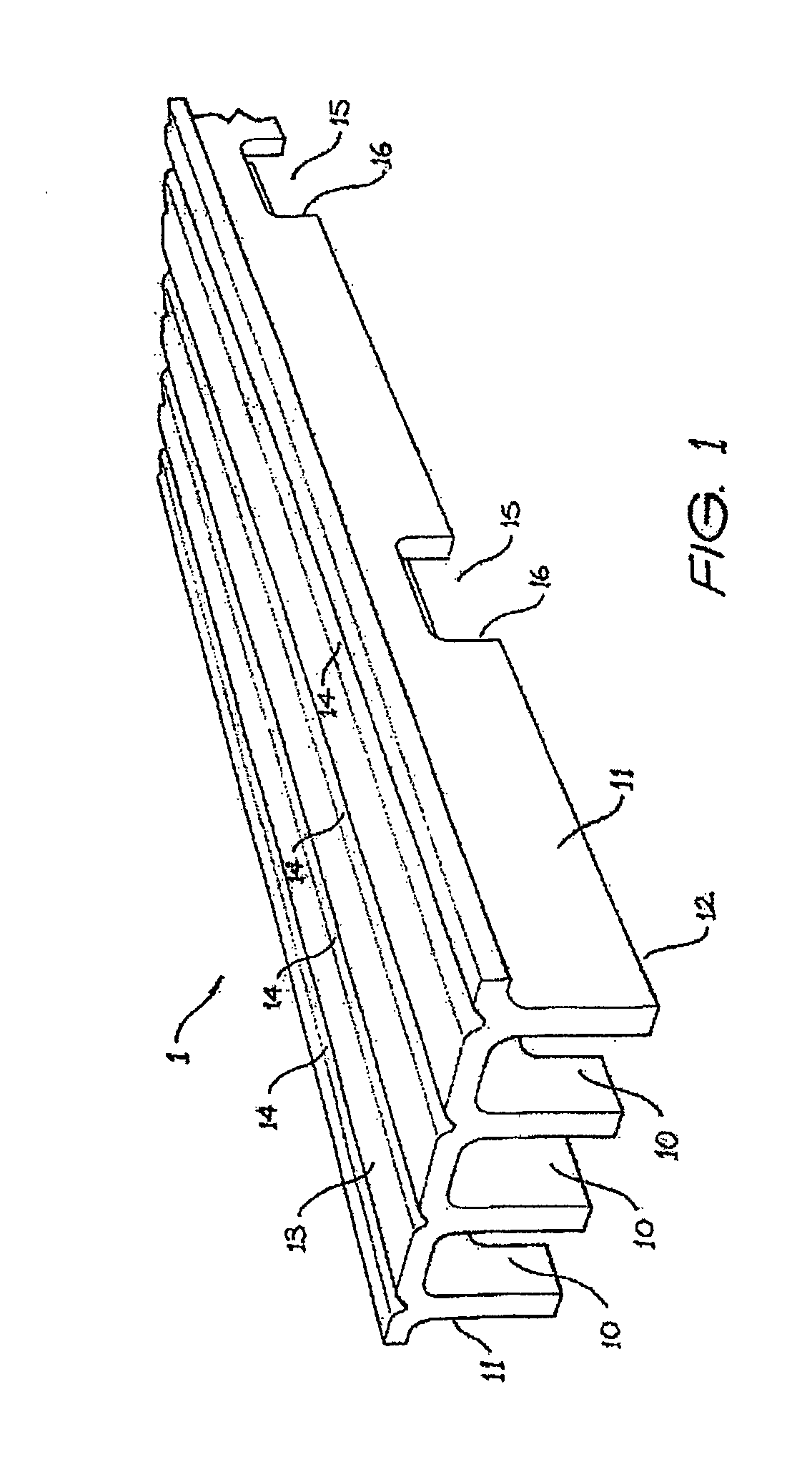

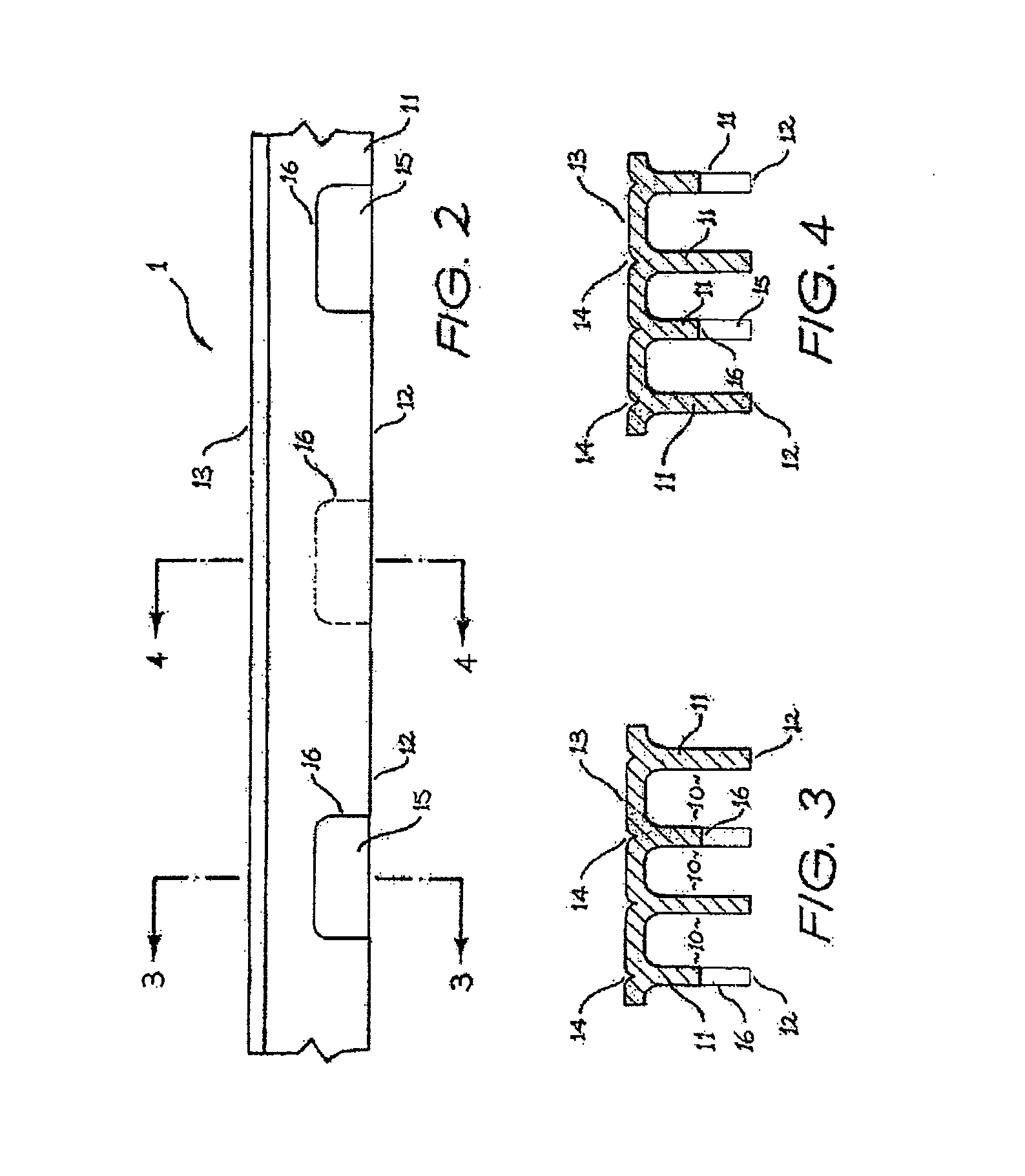

[0038]Referring to the drawings, the invention in a first aspect provides an elongate batten 1 adapted for positioning between an inner wall frame 2 and an outer wall cladding layer 3, to facilitate dispersion and evaporation of moisture from the wall cavity. As best seen in FIGS. 1 to 4, the batten includes a series of generally U-shaped longitudinal channels 10 disposed in parallel side-by-side relationship, and extending along substantially the entire length of the batten. The channels are respectively formed between adjacent pairs of ridges 11, such that the ridges effectively define the inner surface 12 of the batten. The outer surface 13 of the batten includes a corresponding series of generally V-shaped grooves 14, again disposed in parallel, side-by-side relationship and extending along substantially the entire length of the batten. In the embodiment shown, the grooves generally correspond in number and alignment with the respective ridges. This confers the advantage of main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com