Sustained release air freshening device

a technology of air freshening device and suction tube, which is applied in the direction of thin material handling, disinfection, transportation and packaging, etc., can solve the problems of shrinkage, brittleness, cracking, etc., and achieve the effect of inhibiting cracking and splitting, minimizing shrinkage, and clear and transparen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

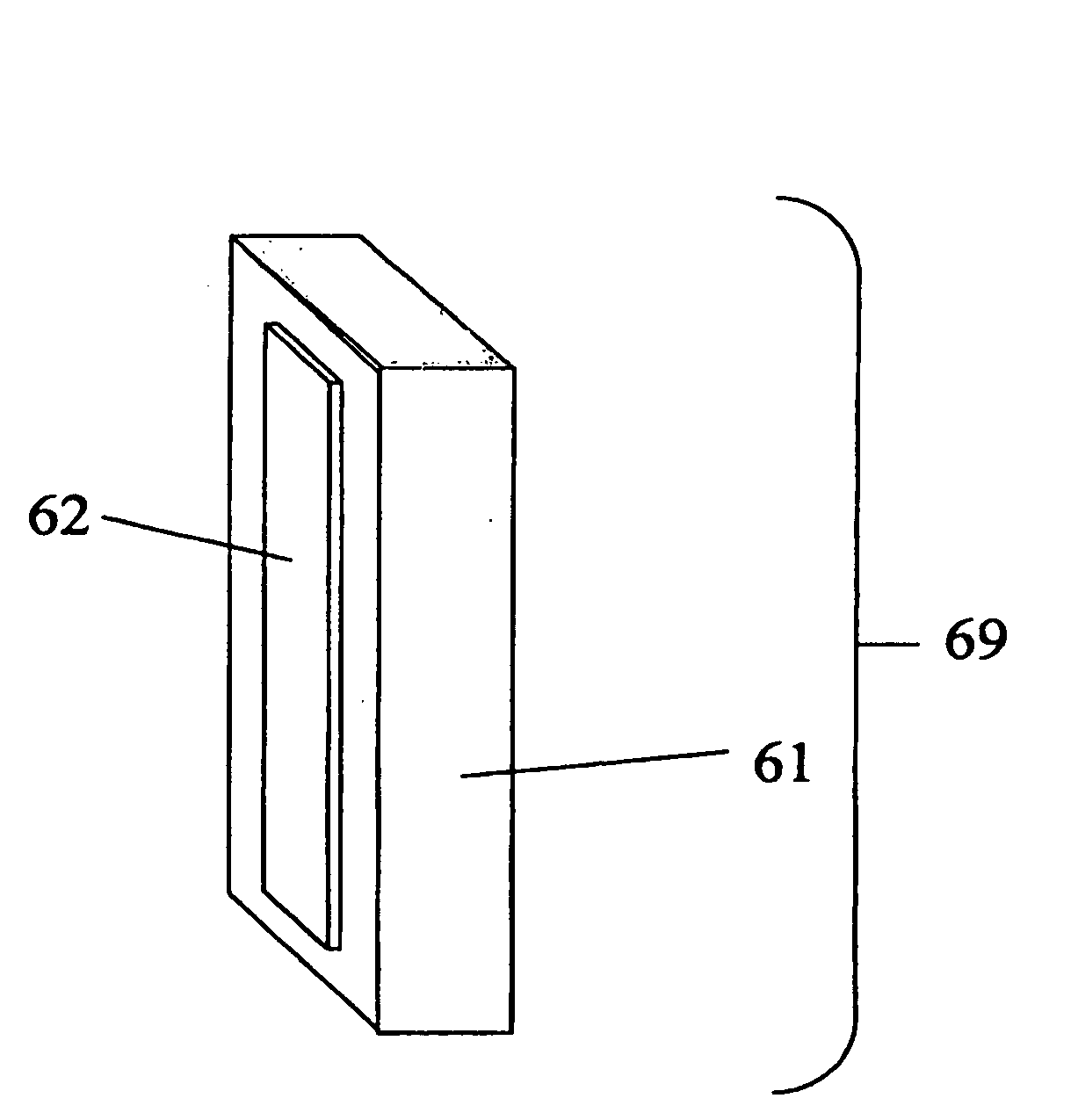

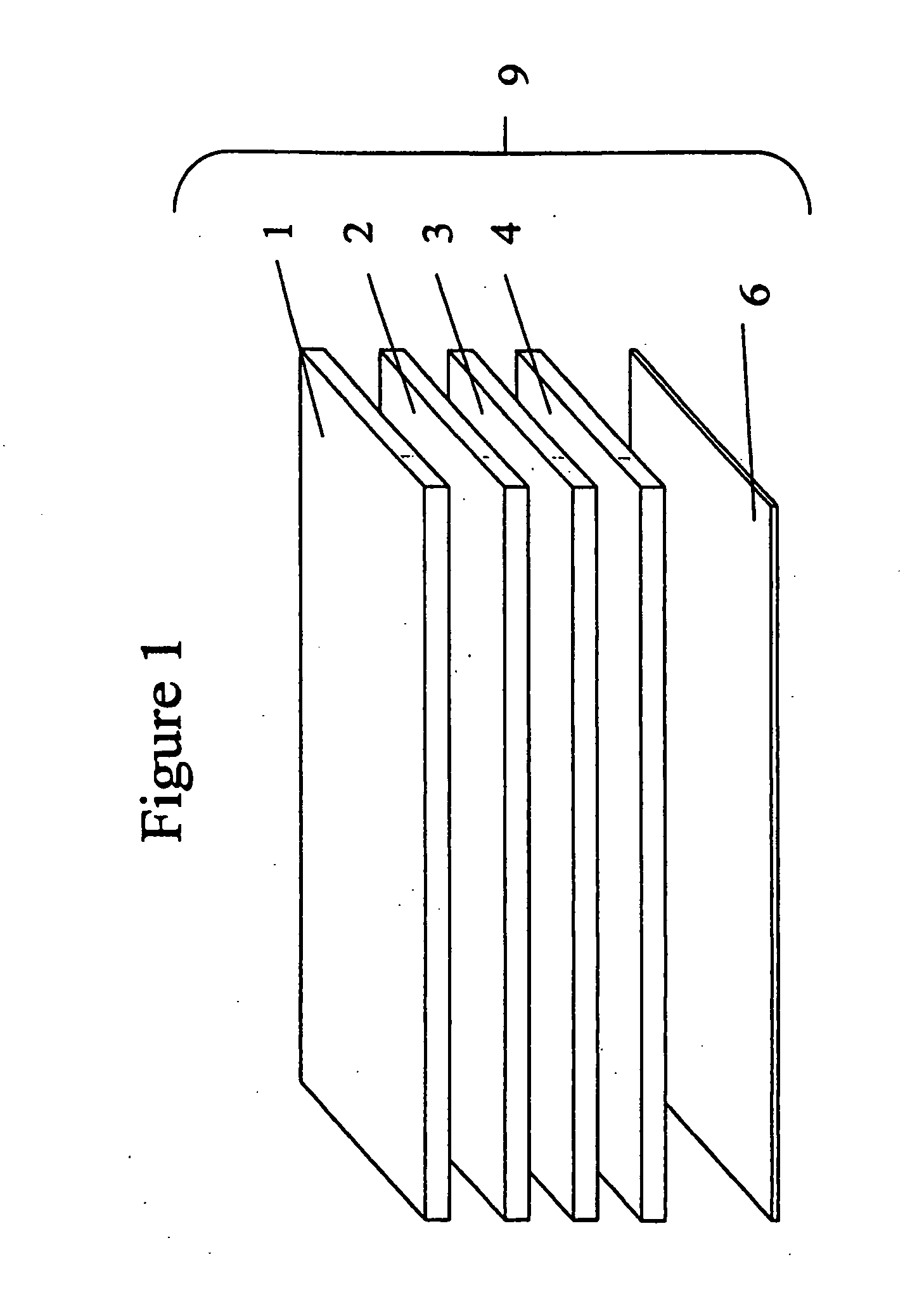

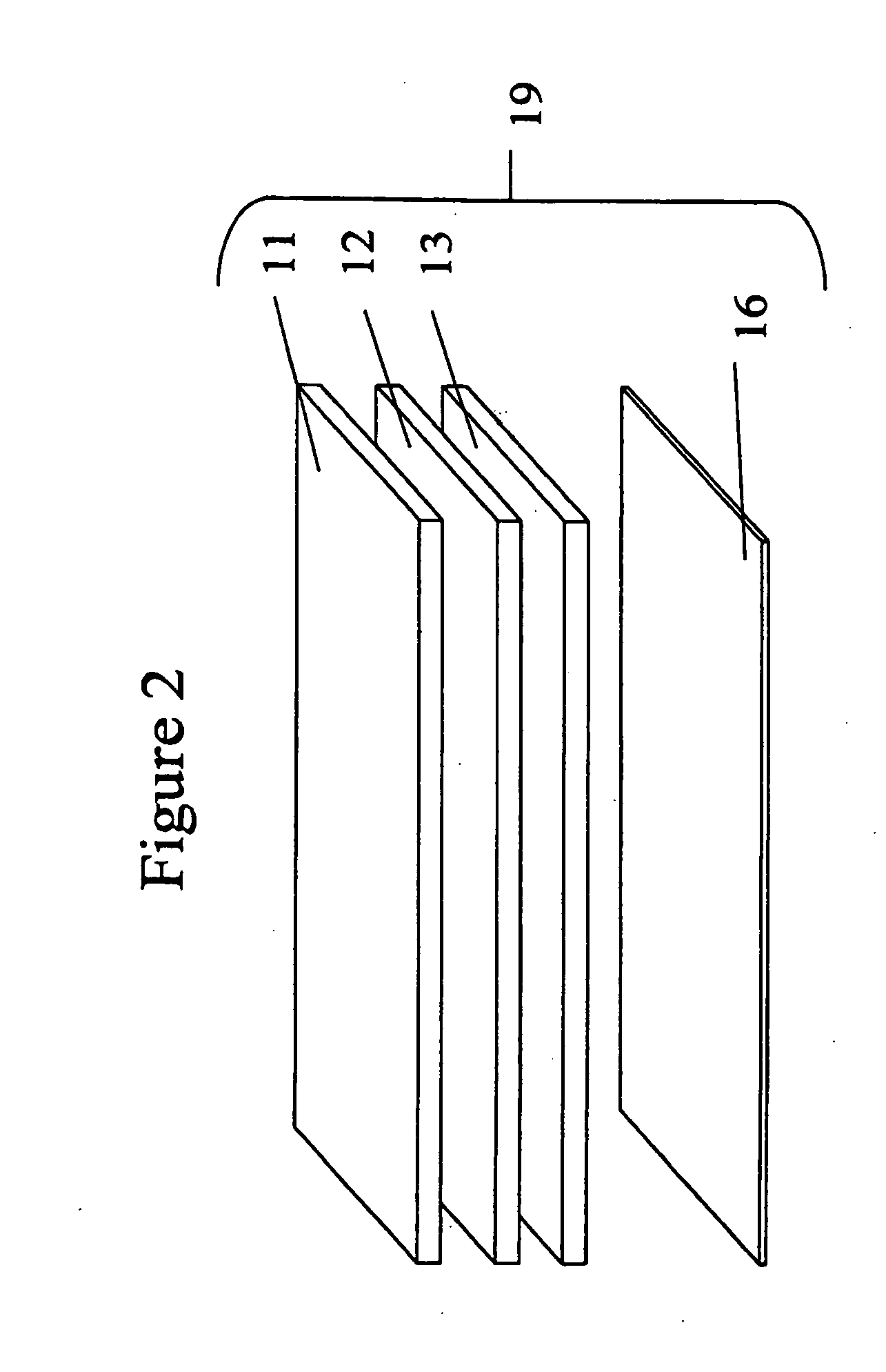

Image

Examples

example 1

Preparation of Hydroxyl-Functional Michael Adduct

[0054]Into a 1000 ml. cylindrical glass reactor were placed 41.94 g. (0.3223 mol.) ethyl acetoacetate, 41.17 g. (0.3545 mol.) 2-hydroxyethyl acrylate, 105.05 g. (0.3545 mol.) trimethylolpropane triacrylate, 1.98 g. (0.00614 mol.) tetrabutylammonium bromide catalyst, and 7.92 g. (0.0557 mol.) glycidyl methacrylate co-catalyst. The flask was fitted with a heating mantle and capped with a reactor cover fitted with a mechanical stirrer, thermometer, and reflux condenser. The reaction mixture was stirred and heated to 95° C. in one hour. The mixture was held at 95° C. and monitored by refractive index and viscosity (Brookfield CAP2000L cone and plate viscometer with Cone #06). After two hours, the refractive index reached 1.4816 (25° C.) and viscosity reached 53.5 poise at 25° C. (500 rpm, 30 sec). The reaction mixture was then cooled to 50° C. and the catalyst was quenched with 1.94 g. (0.00922 mol.) Ebecryl® 168 (UCB Chemicals). The fini...

example 2

Reaction of Michael adduct with Isocyanate-Capped Polybutadiene

[0055]The reactor containing the adduct of Example 1 (1846.6 g) was flushed and blanketed with dry air. To the reactor was added Krasol LBD 2000 (4616.4 g) (toluene diisocyanate polybutadiene prepolymer from Sartomer Company), dibutyltin dilaurate (3.9 g), hydroquinone (0.162 g) and 1,4 naphthoquinone (0.388 g). The mixture was heated with stirring to 80° C. over a one hour period. At the end the hour the pressure in the reactor was reduced 28 mm Hg while the temperature was held constant at 8° C. for 90 minutes. The reactor was brought back to atmospheric conditions. Dipropylene glycol (124.4 g) was added to the mixture. The contents of the reactor were allowed to stir for 30 minutes. A fragrance / solvent blend (3185.4 g) was then added to the reactor along with Irgacure 184 (193.6 g) and Genocure TPO (29.2).

[0056]Sample Preparation

[0057]Approximately 3.5 g of a 33% fragrance / solvent blend containing UV curable, liquid o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt. % | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com