Binary alloy single-crystalline metal nanostructures and fabrication method thereof

a single-crystalline metal nanostructure and alloy technology, applied in the direction of crystal growth process, polycrystalline material growth, chemically reactive gas, etc., can solve the problem of difficult generation of intermetallic compounds, unable to achieve intermetallic compound generation, and the development of improved sensors with excellent sensitivity by domestic and/or oversea research activities is still a long way off, so as to improve simplicity and reproducibility in working processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

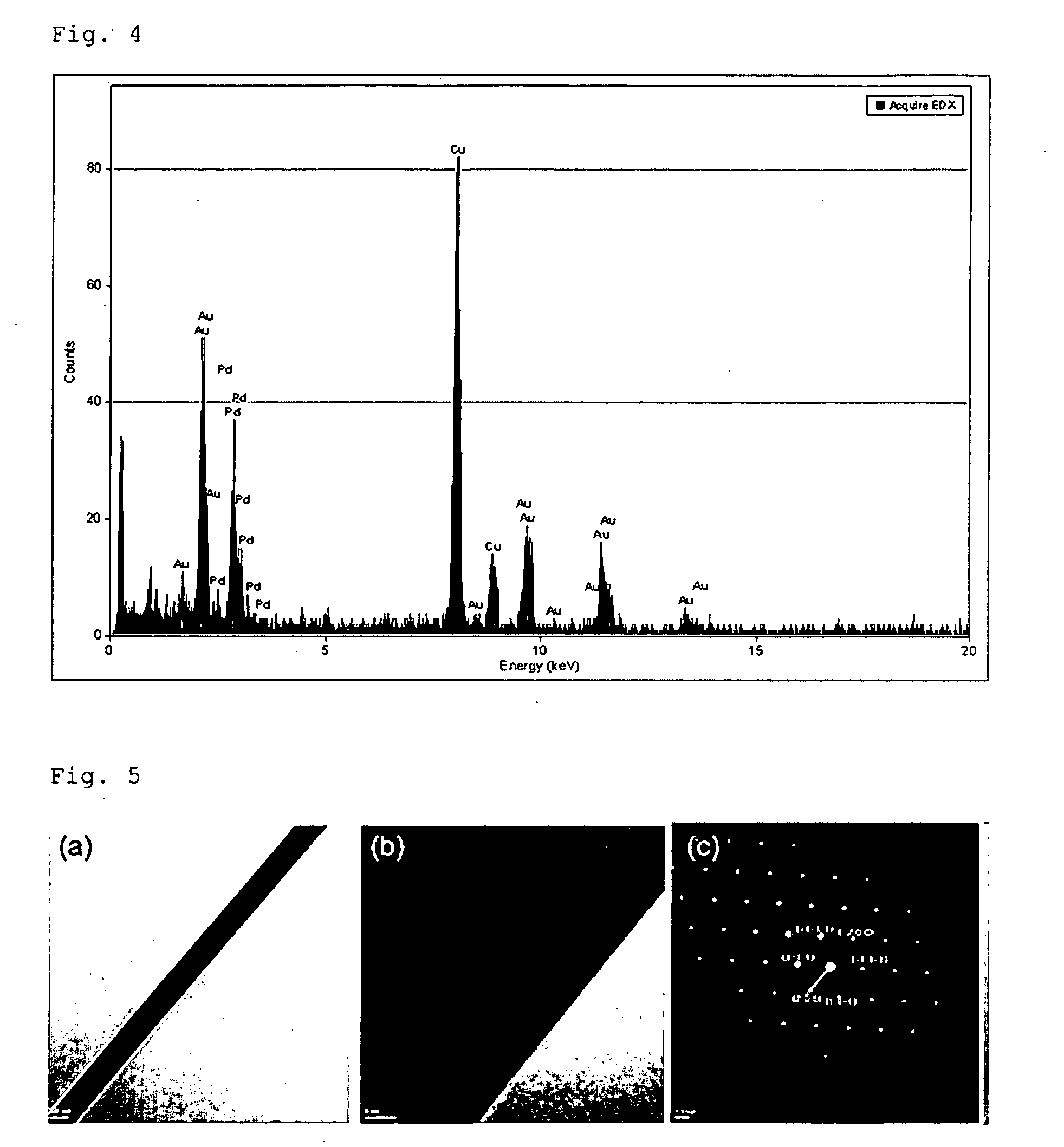

[0082]A PdxAu1-x (0.01≦x≦0.99) single-crystalline metal nanowire was synthesized in a reaction furnace using a vapor phase transport method.

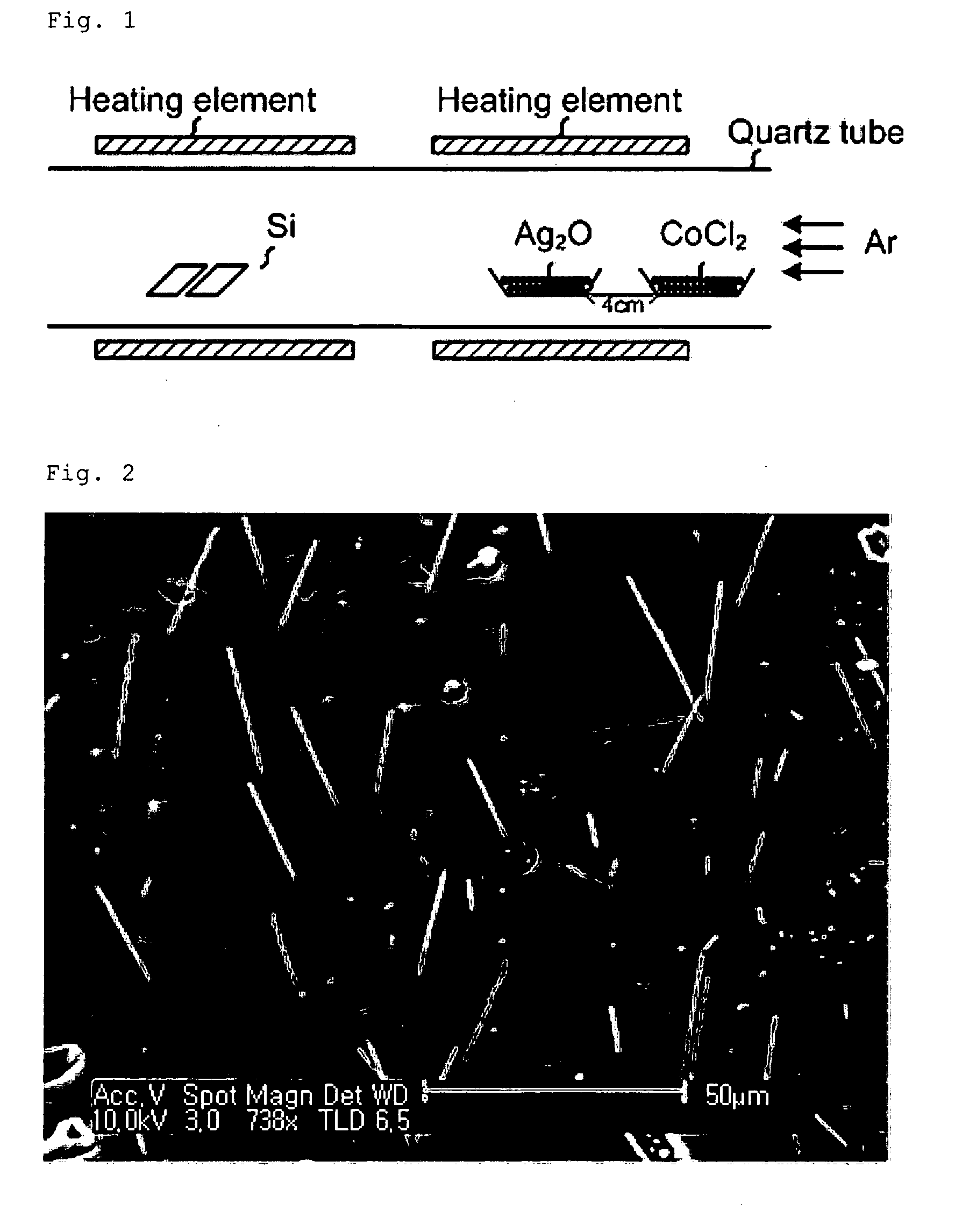

[0083]The reaction furnace is generally divided into front and rear parts and equipped with a heating element and a thermostat, independently. The reaction furnace has a built-in quartz tube with a diameter of 2.54 cm (1 in) and a length of 60 cm (23.6 in).

[0084]A boat type container made of high purity alumina material was located in the middle of the front part of the furnace, to which a mixture including 0.03 g of Au2O3 (Sigma-Aldrich, 334057) and 0.03 g of PdO (Sigma-Aldrich, 203971) was added as a precursor. A sapphire single-crystalline substrate (surface (0001)) was positioned in the middle of the rear part of the reaction furnace. Argon gas flow was introduced to the front part and exhausted out of the rear part of the reaction furnace. To the rear part of the furnace, a vacuum pump was fixed to maintain an internal pressure of the quart...

example 2

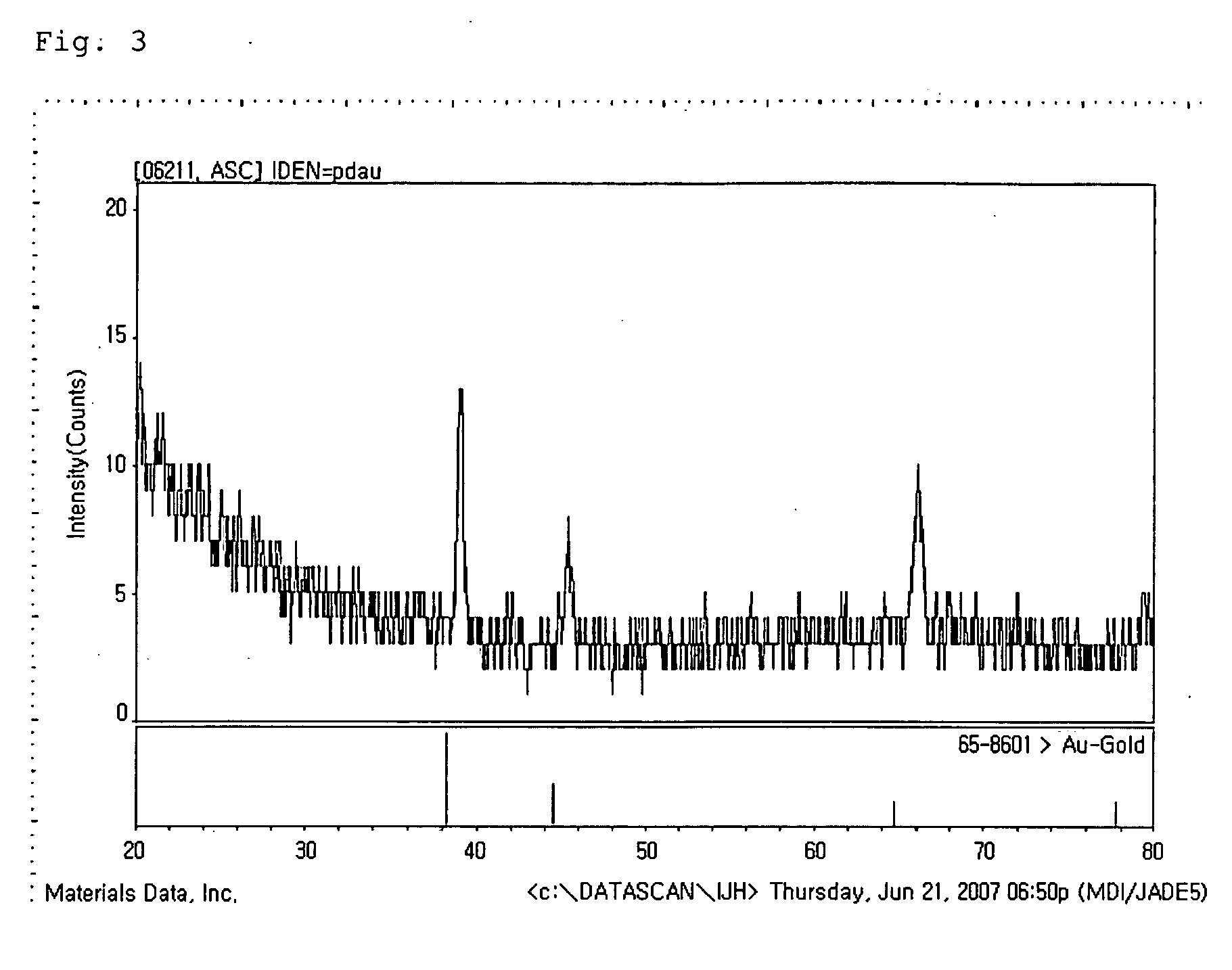

[0086]A CoyAg1-y (0.01≦y≦0.5) single-crystalline metal nanowire was synthesized in a reaction furnace using a vapor phase transport method.

[0087]The reaction furnace is generally divided into front and rear parts and equipped with a heating element and a thermostat, independently. The reaction furnace has a built-in quartz tube with a diameter of 2.54 cm (1 in) and a length of 60 cm (23.6 in).

[0088]Two boat type containers made of high purity alumina material were located in the middle of the front part of the furnace, in which 0.01 g of CoCl2 (Sigma-Aldrich, 449776) and 0.3 g of Ag2O (Sigma-Aldrich, 22163) were placed as precursors, respectively. A Si single-crystalline substrate (surface (100)) was positioned in the middle of the rear part of the reaction furnace. A melting pot made of alumina containing Au2O3 was placed in the middle of the front part of the reaction furnace.

[0089]Argon gas flow was introduced to the front part and exhausted out of the rear part of the reaction f...

example 3

[0092]An Ag2Te single-crystalline metal nanowire was synthesized in a reaction furnace using a vapor phase transport method.

[0093]The reaction furnace is generally divided into front and rear parts and equipped with a heating element and a thermostat, independently. The reaction furnace has a built-in quartz tube with a diameter of 2.54 cm (1 in) and a length of 60 cm (23.6 in).

[0094]A boat type container made of high purity alumina material was located in the middle of the front part of the reaction furnace, in which 0.05 g of Ag2Te (Sigma-Aldrich, 400645) was placed as a precursor. A Si single-crystalline substrate (surface (100)) was positioned in the middle of the rear part of the reaction furnace.

[0095]Ar gas flow was introduced to the front part and exhausted out of the rear part of the reaction furnace. To the rear part of the furnace, a vacuum pump was fixed to maintain an internal pressure of the quartz tube at 10 torr. Ar gas flow rate was controlled to 200 sccm using MFC....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com