Boiler

a boiler and boiler body technology, applied in the field of boilers, can solve the problems of difficult to achieve incompatible technical requirements for simultaneous reduction of nox and co, and relatively small capacity of water-tube boilers, so as to achieve stably the effect of reducing hazardous substances, reducing nox and co, and simplifying the configuration of the apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment mode 2

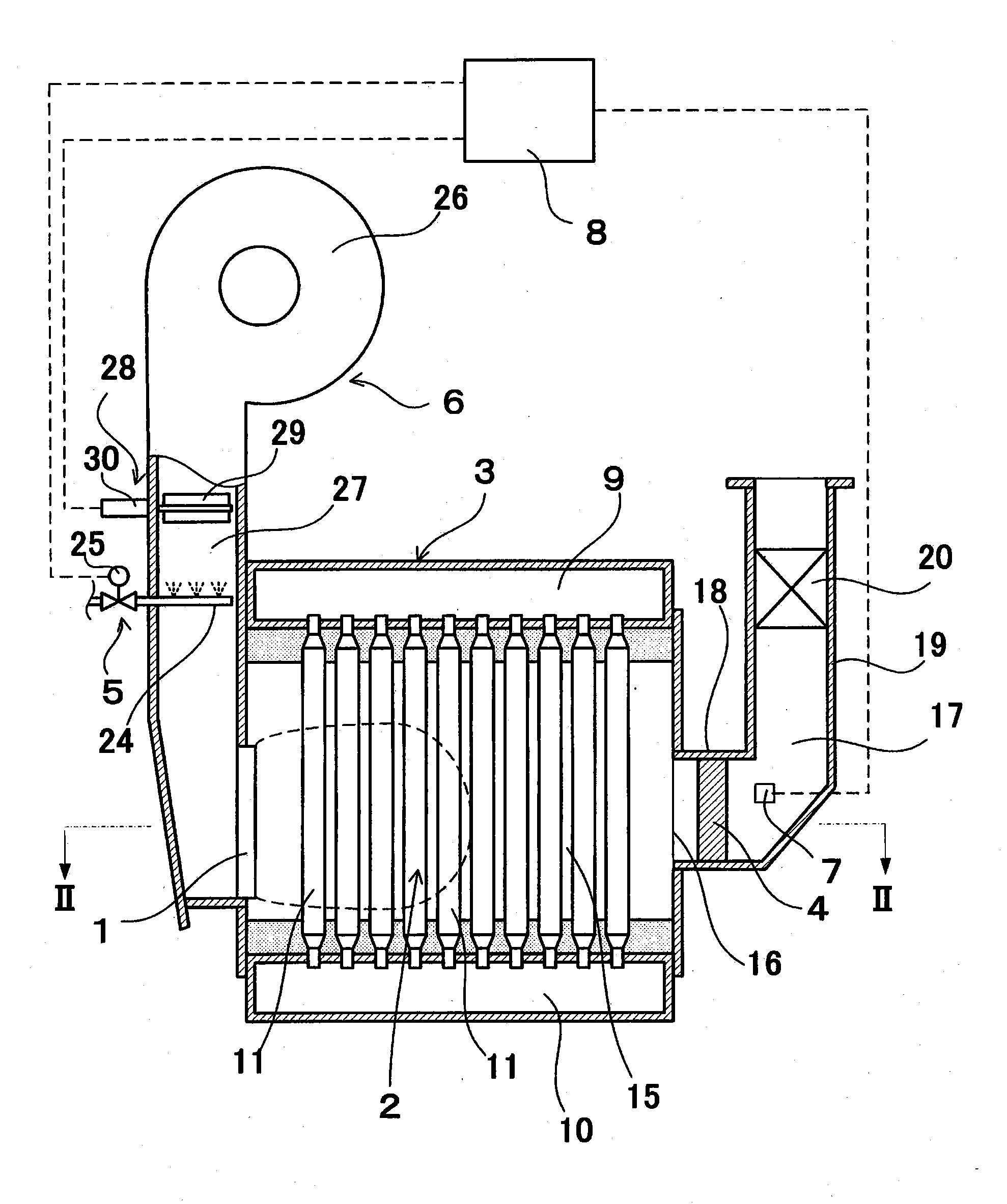

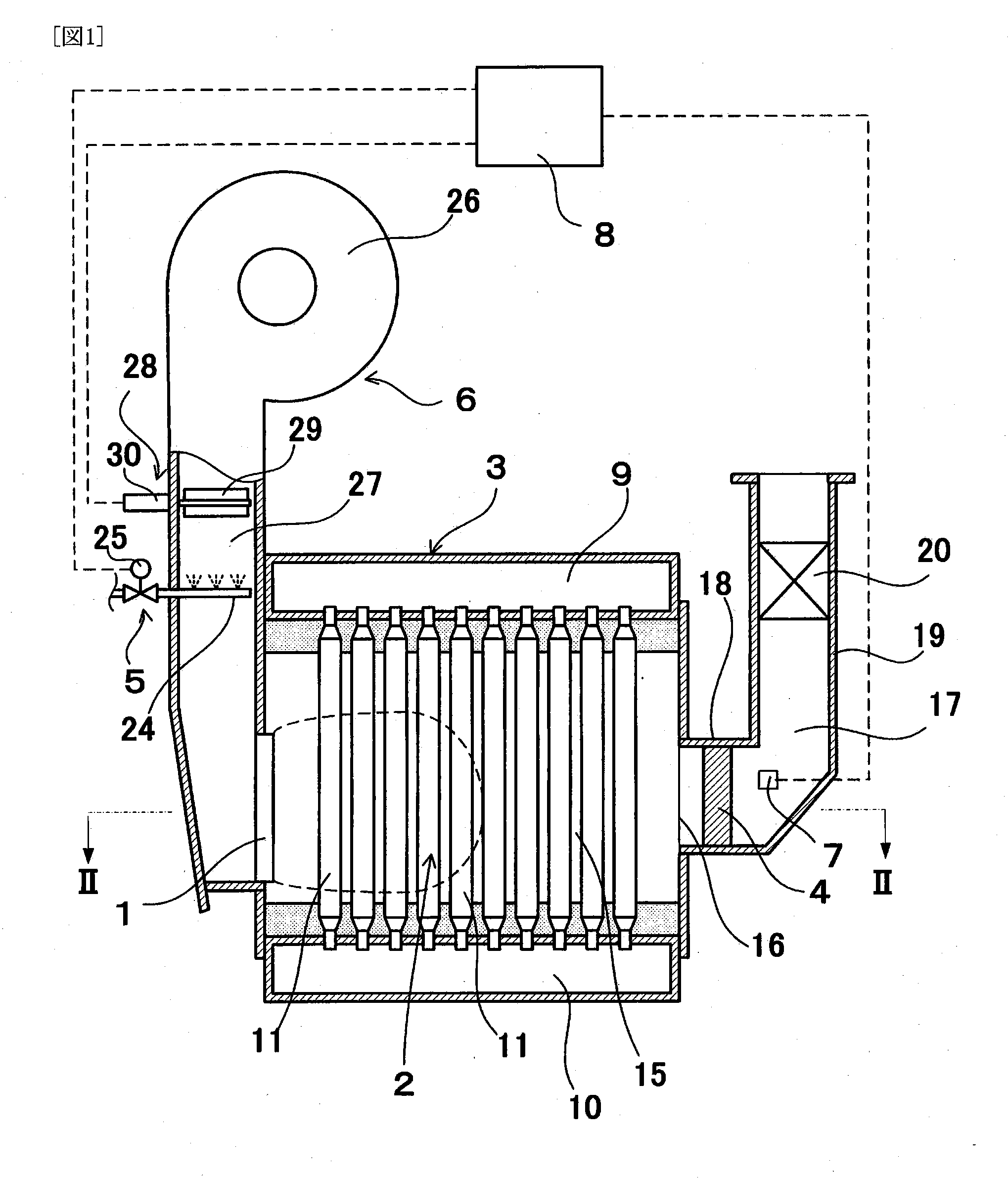

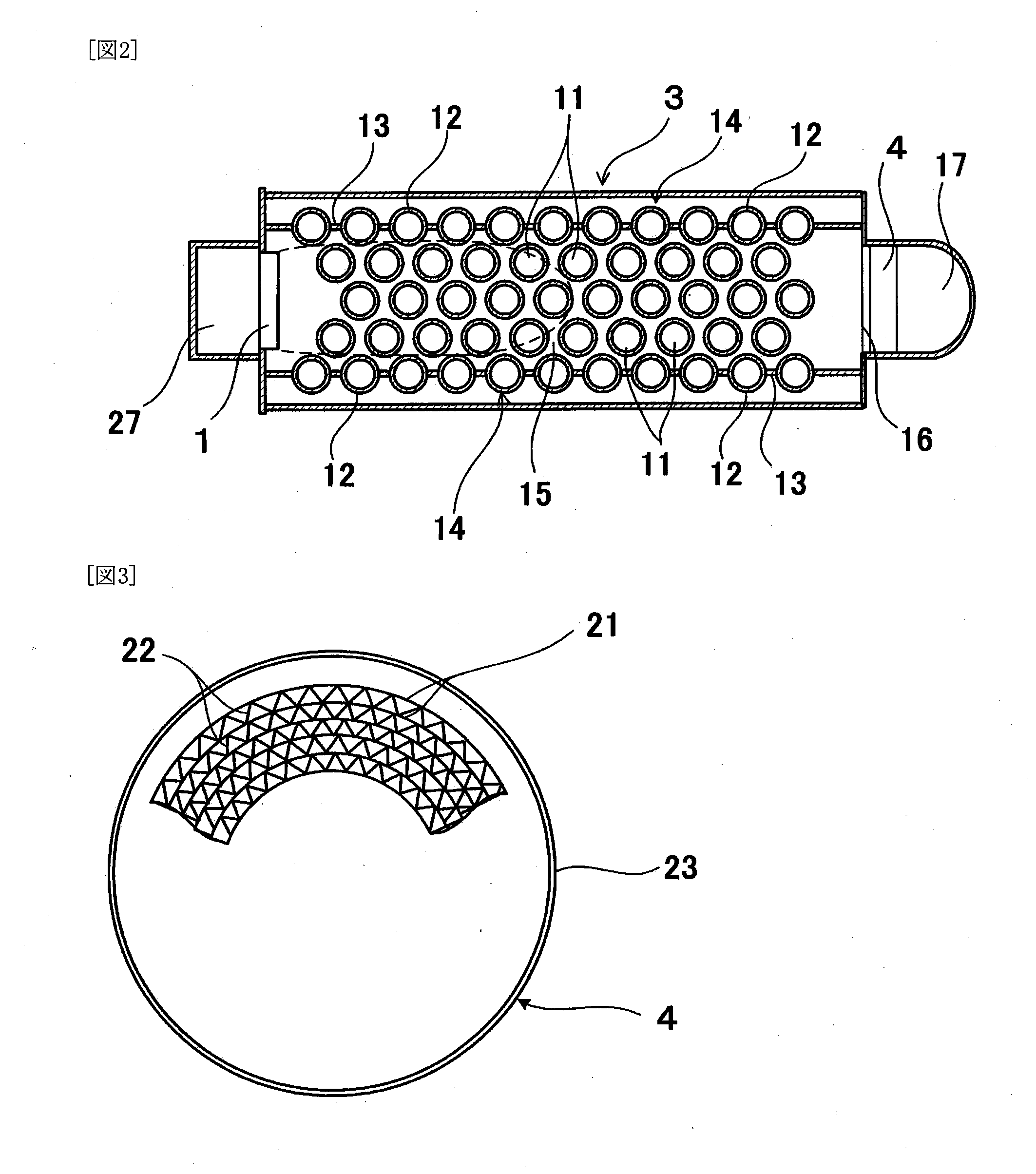

[0084]Embodiment 2 is a boiler including: a premixed burner for burning a hydrocarbon-containing fuel to generate gas free of hydrocarbon but containing oxygen, nitrogen oxides, and carbon monoxide; a water tube group for absorbing heat from gas generated by the premixed burner; an oxidation catalyst for oxidizing the carbon monoxide contained in the gas after the passage through the water tube group by oxygen and reducing the nitrogen oxides contained in the gas by carbon monoxide; and air-ratio adjusting device for adjusting an air ratio of the premixed burner, in which the premixed burner and the water tube group have characteristics in which a concentration ratio K among oxygen, nitrogen oxides, and carbon monoxide in gas on a primary side of the oxidation catalyst becomes a predetermined reference concentration ratio K0, assuming that the air ratio is a set reference air ratio, the oxidation catalyst has characteristics in which the concentrations of nitrogen oxides and carbon ...

embodiment mode 3

[0085]Further, Embodiment Mode 3 is a boiler including: a premixed burner for burning a hydrocarbon-containing fuel to generate gas free of hydrocarbon but containing oxygen, nitrogen oxides, and carbon monoxide; a water tube group for absorbing heat from gas generated by the premixed burner; an oxidation catalyst for oxidizing the carbon monoxide contained in the gas after the passage through the water tube group by oxygen and reducing the nitrogen oxides contained in the gas by carbon monoxide; and air-ratio adjusting device for adjusting an air ratio of the premixed burner, in which the premixed burner and the water tube group have characteristics in which a concentration ratio K among oxygen, nitrogen oxides, and carbon monoxide in gas on a primary side of the oxidation catalyst becomes a first predetermined concentration ratio K1, assuming that the air ratio is a first set air ratio, assuming that the air ratio is a first set air ratio, the oxidation catalyst has characteristic...

embodiment mode 4

[0095]The present invention includes Embodiment 4 as described below. Embodiment Mode 4 is a boiler including: a premixed burner for burning a hydrocarbon-containing fuel to generate gas free of hydrocarbon but containing oxygen, nitrogen oxides, and carbon monoxide; a water tube group for absorbing heat from gas generated by the premixed burner; an oxidation catalyst for oxidizing the carbon monoxide contained in the gas after the passage through the water tube group by oxygen and reducing the nitrogen oxides contained in the gas by carbon monoxide; a sensor for detecting an air ratio of the premixed burner; and air-ratio adjusting device for controlling the premixed burner to a set air ratio based on the detection signal of the sensor, in which the premixed burner and the water tube group are configured so as to obtain a predetermined concentration ratio of oxygen, nitride oxides, and carbon monoxide on a primary side of the oxidation catalyst at which the concentration of nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com