Downhole Electric Driven Pump Unit

a technology of electric drive and pump unit, which is applied in the direction of fluid removal, positive displacement liquid engine, borehole/well accessories, etc., can solve the problems of low pump lift performance, short service life of flexible plane diaphragm, etc., to increase the pump's lift performance, avoid wear, and double the pump's capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

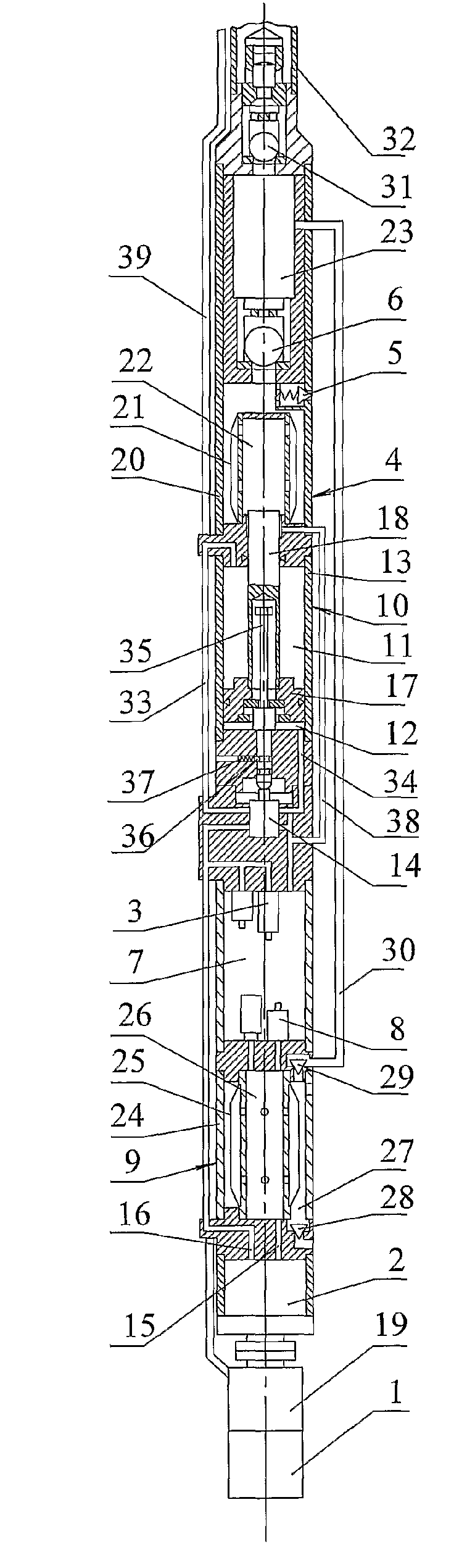

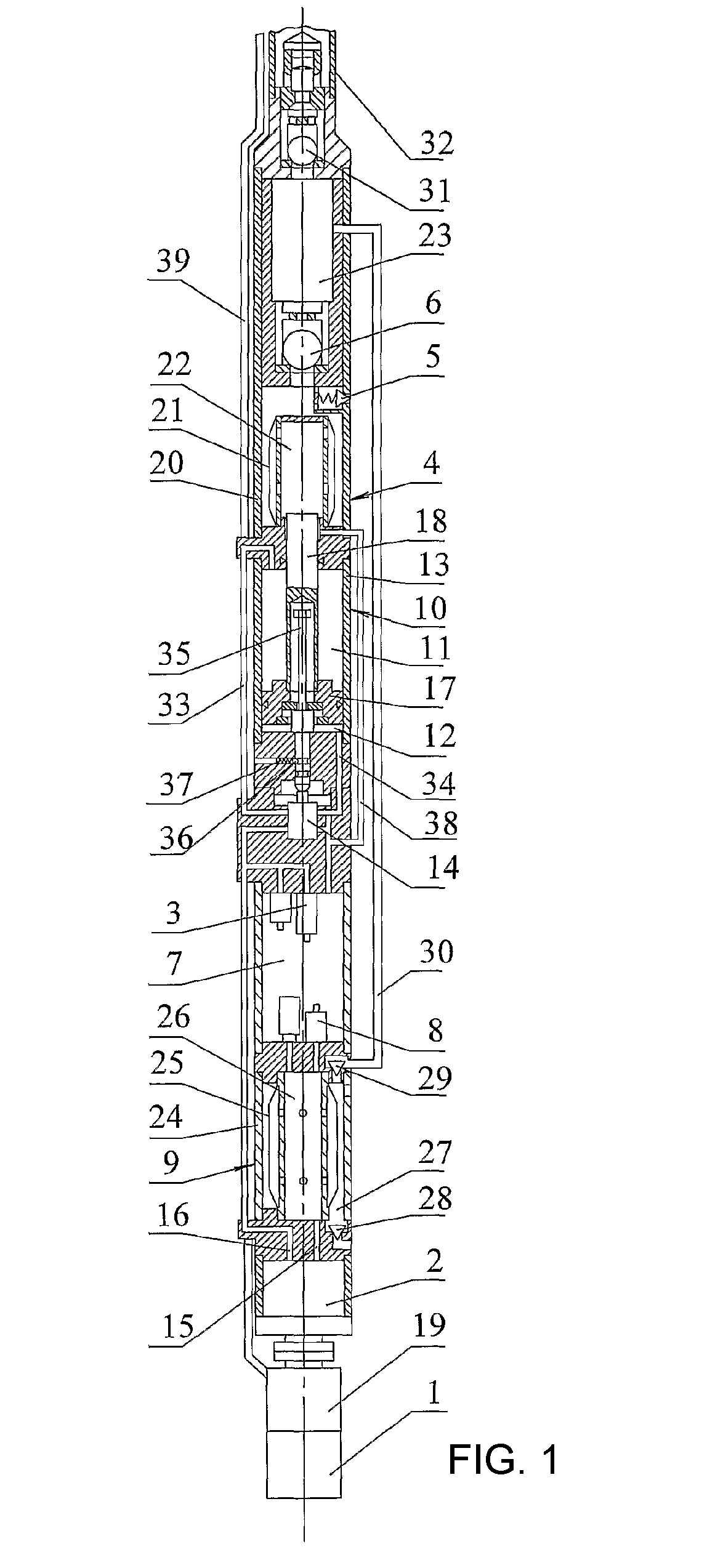

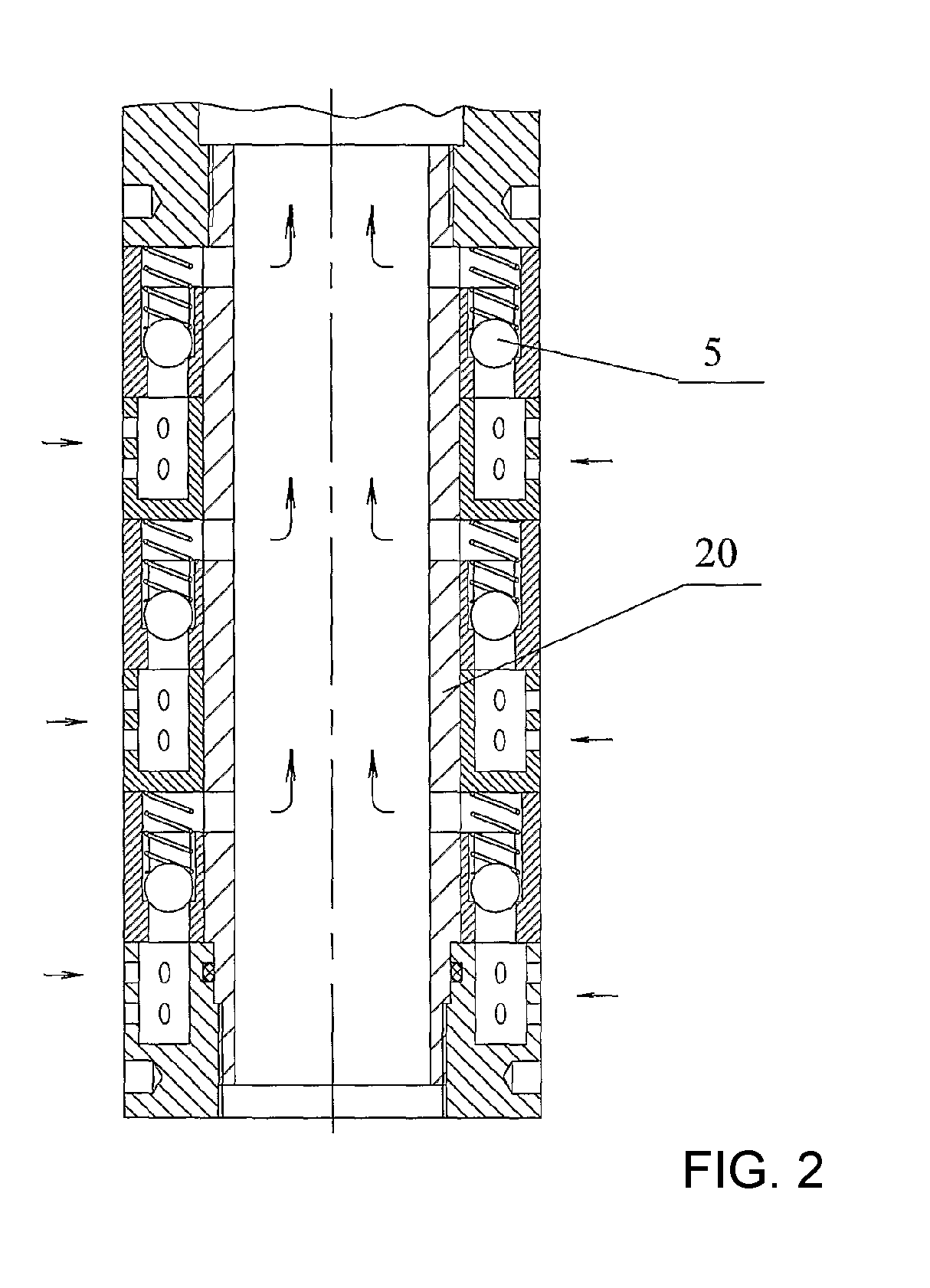

[0011]The electric hydraulically actuated well pump consists of submersible electric motor 1, engine-driven oil pump 2, plunger working pump 4 with suction 5 and pressure 6 valves, oil tank 7 with fine media oil filters 8, oil expansion joint 9 and hydraulic motor 10, and head-piston 11 and bottom-piston 12 chambers of cylinder 13, which are connected through control valve 14 to the suction 15 and pressure 16 sides of oil pump 2, (the latter of which is equipped with safety valve 3), and piston 17 of hydraulic motor 10 is connected to plunger 18 of working pump 4. Electric motor 1 is equipped with protector 19, the shaft of which kinematically connects the shaft of electric motor 1 to the shaft of engine-driven oil pump 2. An axial piston pump is used as engine-driven oil pump 2, and cylinder 20 of plunger working pump 4 is equipped with hermetic cylindrical flexible diaphragm 21, which forms chamber 22 filled with oil in cylinder 20. Plunger 18 of working pump 4 is capable of recip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com