Well servicing combination unit

a combination unit and well technology, applied in the direction of borehole/well accessories, drilling casings, drilling pipes, etc., can solve the problems of limiting the equipment that each can drive, increasing the mass and volume of transportation, and limiting the number of integrated units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

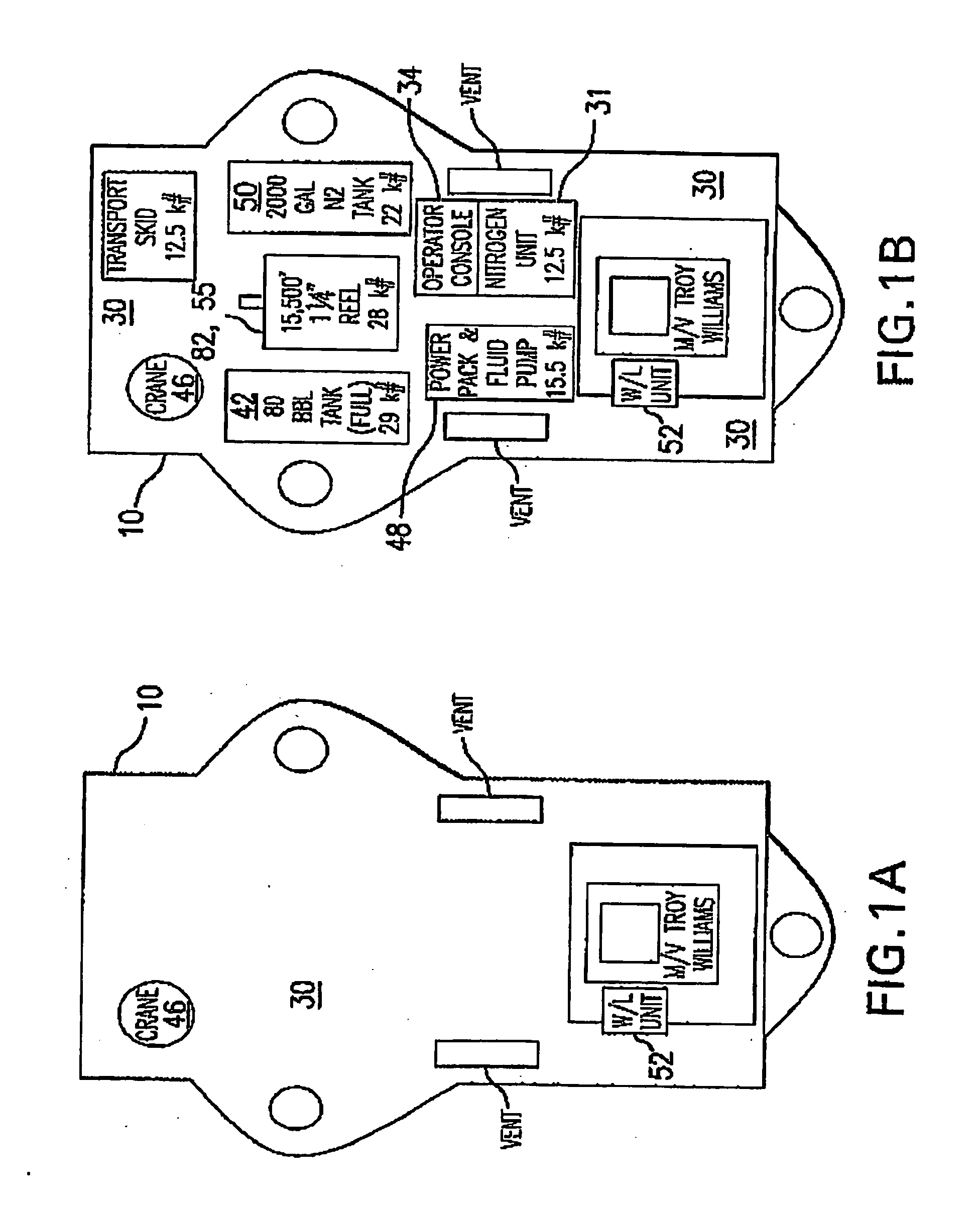

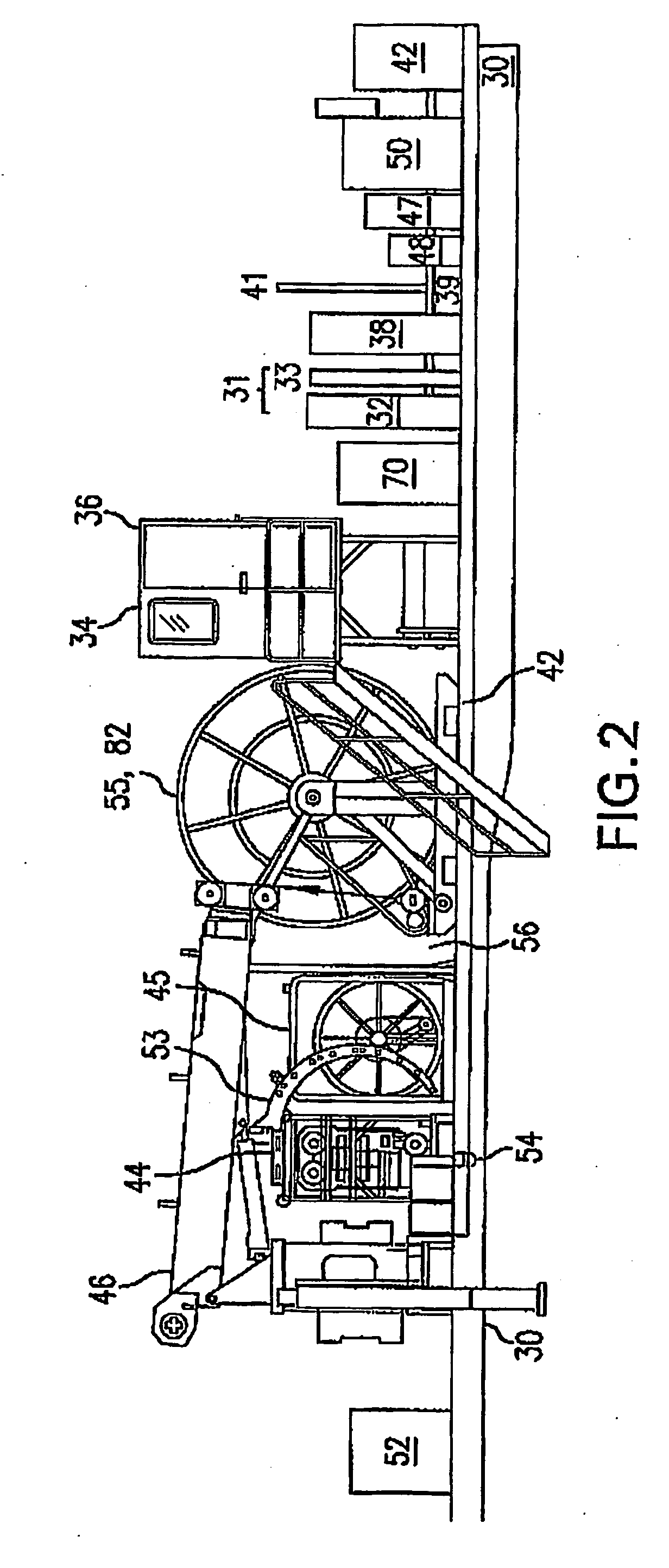

[0028]Referring now to FIG. 1, a top view of jack-up boat 10 having either a gasoline engine or a diesel engine is illustrated. Mounted on the boat deck 30 is nitrogen generator 31 (also shown in FIG. 4) that extracts nitrogen from the atmosphere to eliminate the need for (and the associated cost of) transporting and filling nitrogen tanks. Mounted to boat deck 30 are chemical storage tanks 42 that supply chemicals to blending tanks 50 where the chemicals arc mixed. The mixed chemicals flow to the well servicing fluid pump 48. The mixed chemicals may flow through the coil tubing 82, 50 to the well head. Wireline inspection unit 52 is mounted to deck 30. Also mounted on the deck 30 is control cabin 34 in which the electrical and hydraulic units 36 are controlled by a human operator. Components arc described in greater detail in the description of FIG. 2 below.

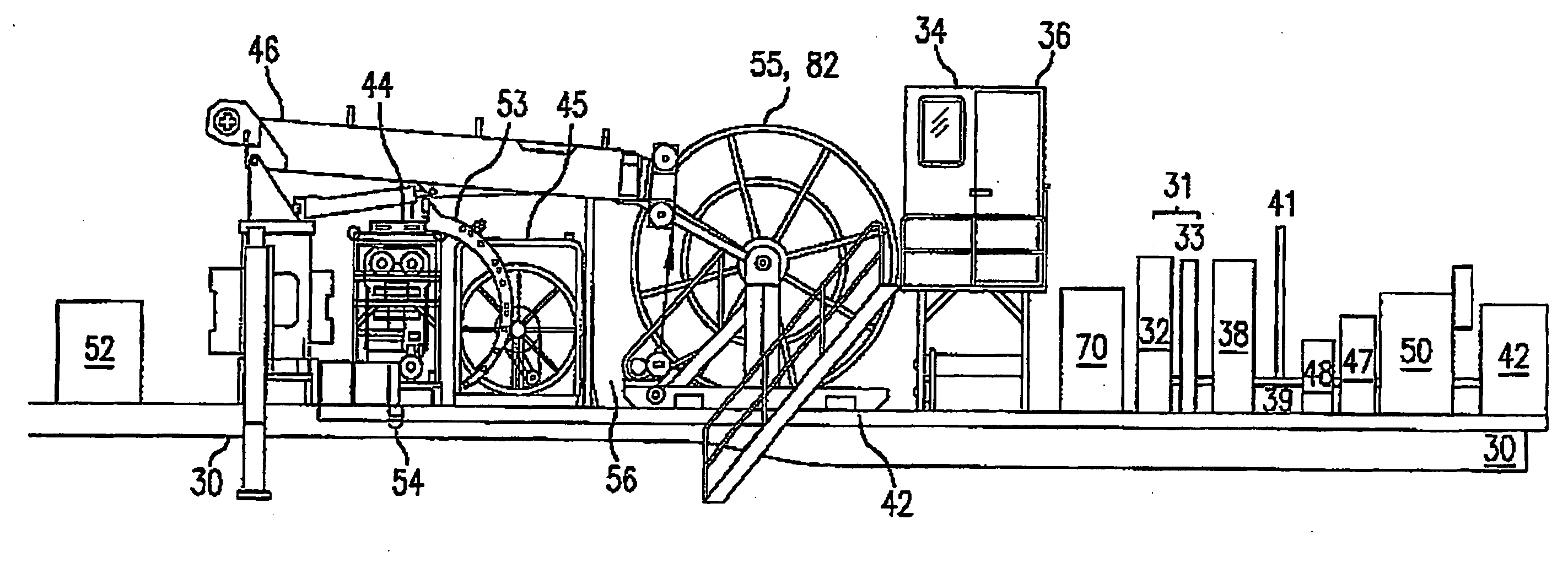

[0029]Referring now to FIG. 2, a diagram of a jack-up boat 10 is illustrated. Mounted on the boat deck 30 is a custom hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com