Lubricating coating composition suitable for tubular threaded joints

a technology for tubular threaded joints and coating compositions, applied in the preparation of carboxylic compounds, screw threaded joints, organic compounds of the 3/13 element group, etc., can solve the problems of increasing environmental regulations, difficult use, and inability to assess the environmental impact of coating compositions, and achieve satisfactory galling resistance and anticorrosion properties, high biodegradability, and no environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

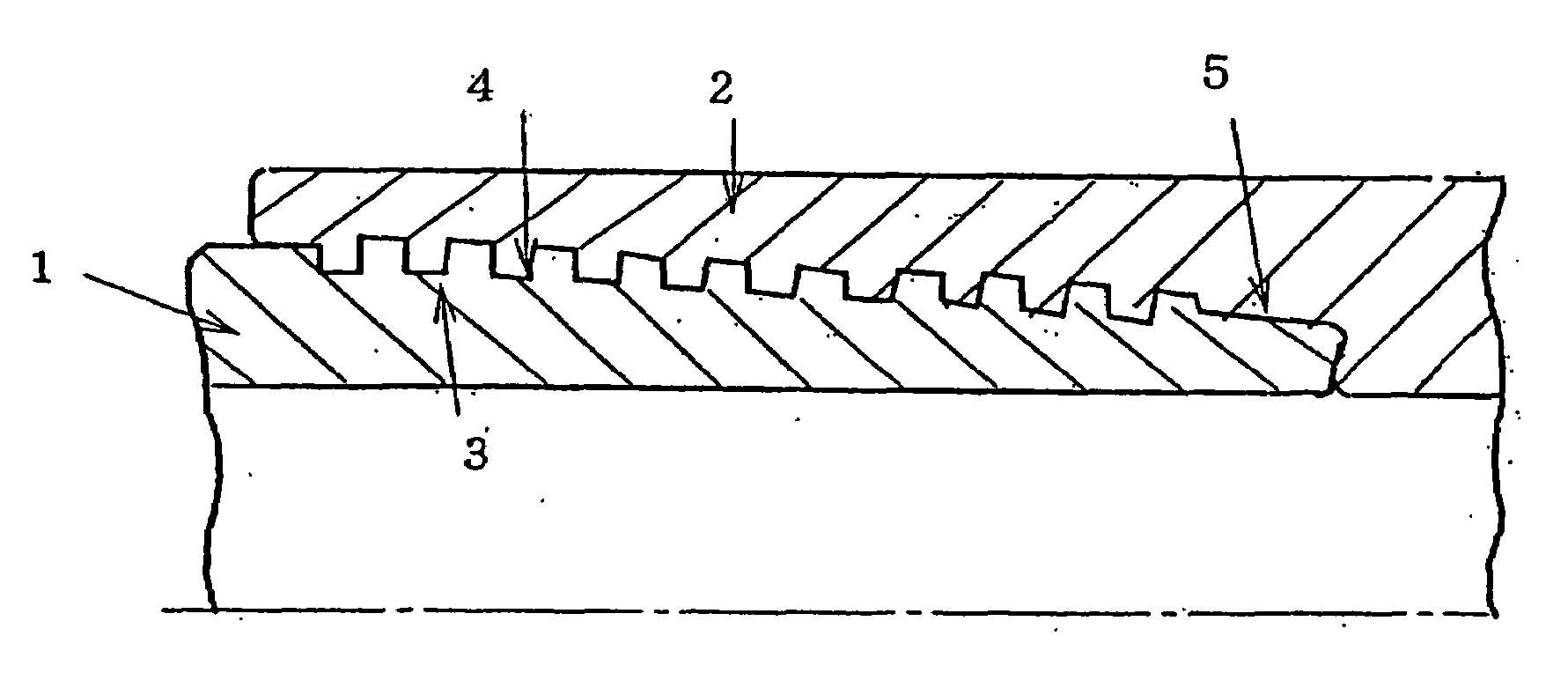

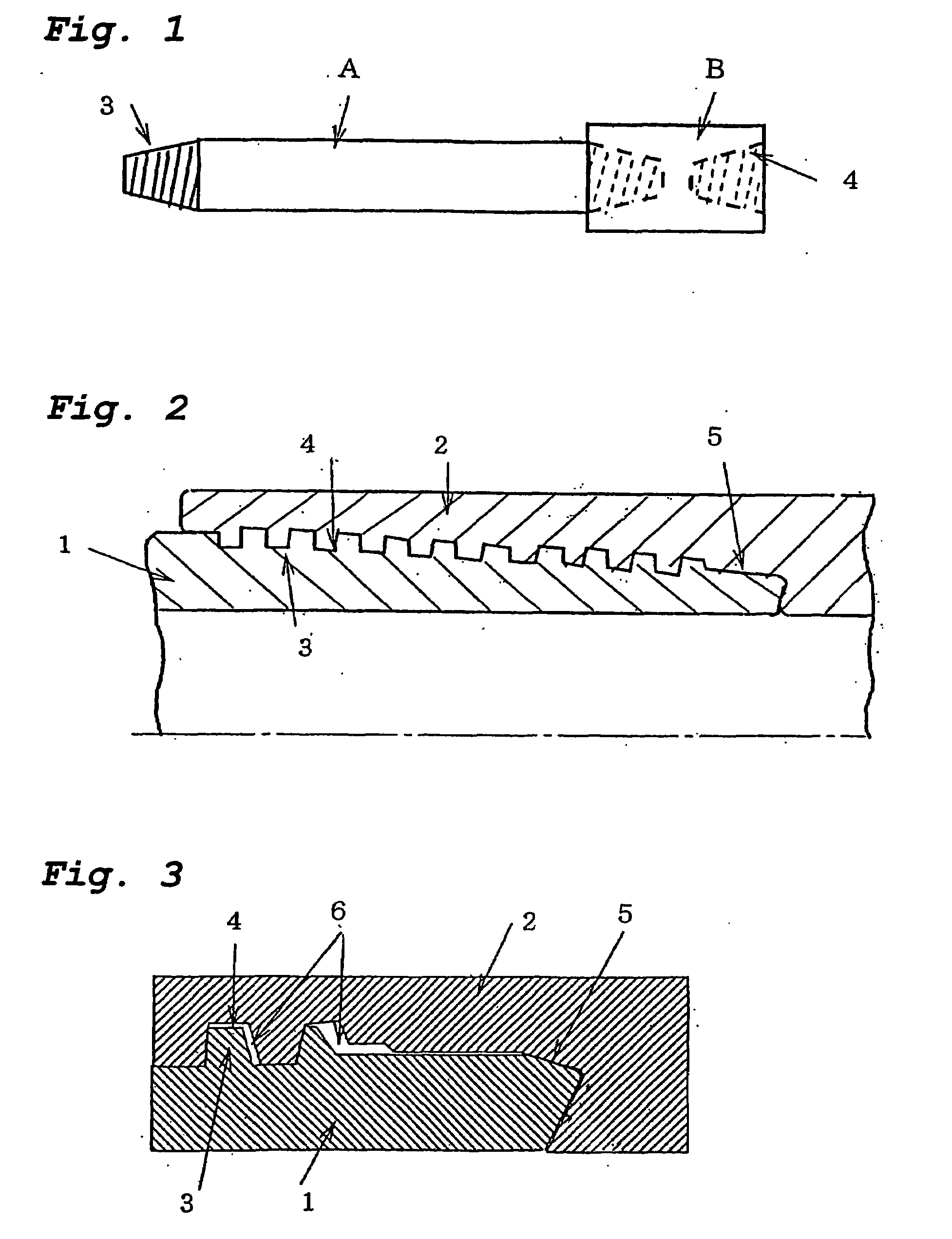

Image

Examples

example 1

[0109]A lubricating coating composition was prepared which contained 25% of mineral spirit as a dissolving medium, 50% (66.7 parts) of basic calcium sulfonate having a base number of 400 mg-KOH / g as a basic lubricant, and 17% (22.7 parts) of calcium stearate and 8% (10.6 parts) of petrolatum wax both as additional lubricants. The parts in parentheses are the amounts of the respective components in parts by mass based on 100 parts by mass of the total amount of the components in the composition excluding the dissolving medium.

[0110]This lubricating coating composition contained a dissolving medium and thus had a low viscosity and a high spreadability, so it was easy to apply and could be applied by brush coating to the box surface of a test threaded joint to be used in a repeated tightening and loosening test and the surface of a test sheet for a salt spray test while remaining at room temperature. On the other hand, due to the presence of a dissolving medium which does not have good...

example 2

[0112]A lubricating coating composition was prepared which did not contain a dissolving medium but contained 65% of the same basic calcium sulfonate as used in Example 1 as a basic lubricant, and 23% of calcium stearate and 12% of petrolatum wax both as additional lubricants.

[0113]Since this lubricating coating composition did not contain a dissolving medium and thus had a high viscosity at room temperature, it was previously heated to 60° C. to lower its viscosity and then applied by brush coating to the box surface of a test threaded joint to be used in a repeated tightening and loosening test and the surface of a test sheet for a salt spray test. On the other hand, due to the absence of a dissolving medium, it had good biodegradability, and the biodegradability (BOD28) of the entire lubricating coating composition in seawater was 36%, which greatly exceeded the minimum acceptable value of 20%, and was higher than that of the composition of Example 1 containing a dissolving medium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com