Fischer-tropsch jet fuel process

a jet fuel and process technology, applied in the field of jet fuel production, can solve the problems of limited yield of kerosene range material that can be obtained in practice, high freezing point and low temperature viscosity, and low aromatic content, so as to reduce complexity, high linearity, and high freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

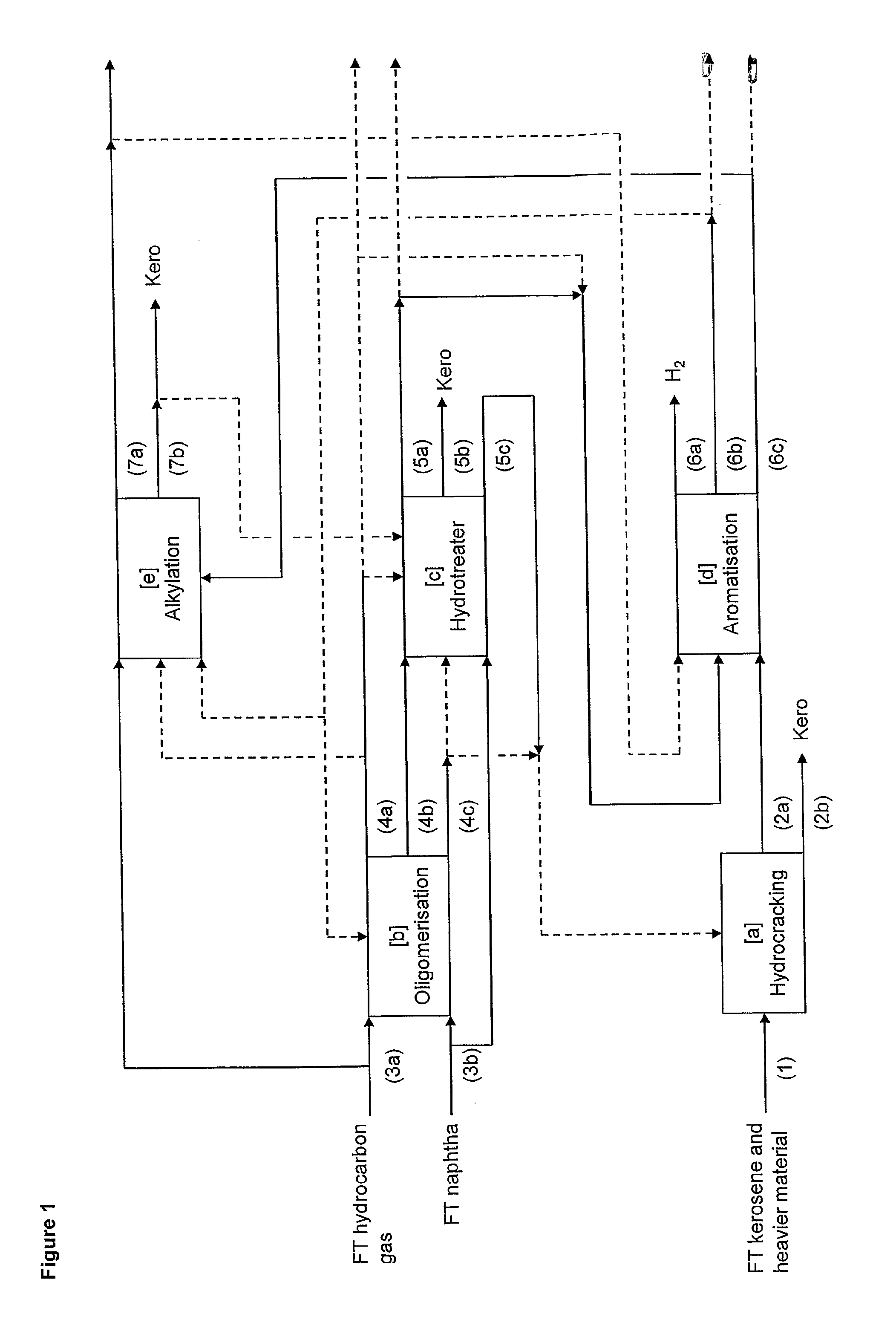

[0079]The jet fuel refinery design in this example as shown in FIG. 2 is based on the feed from a HTFT. The aim of this example is to show how much jet fuel can be produced from Fischer-Tropsch syncrude using the present invention.

[0080]The Fischer-Tropsch C9 and heavier syncrude (boiling point typically >130° C.) is used as feed stream 1 to the hydrocracker unit [a], which is operated in accordance with the description of this invention. The C16 and heavier distillate range product (boiling point typically >280° C.) from olefin oligomerisation stream 4c is first hydrotreated to produce stream 5c and then also hydrocracked. This results in the production of mainly kerosene stream 2b with a yield of around 75% on a fresh feed basis. The C3-C8 light hydrocarbons stream 2a are routed to the aromatisation unit [d].

[0081]Fischer-Tropsch C6-C8 syncrude (boiling range typically 40-130° C.) is used without pretreatment as feed stream 3b to the oligomerisation unit [b]. The oligomerisation p...

example 2

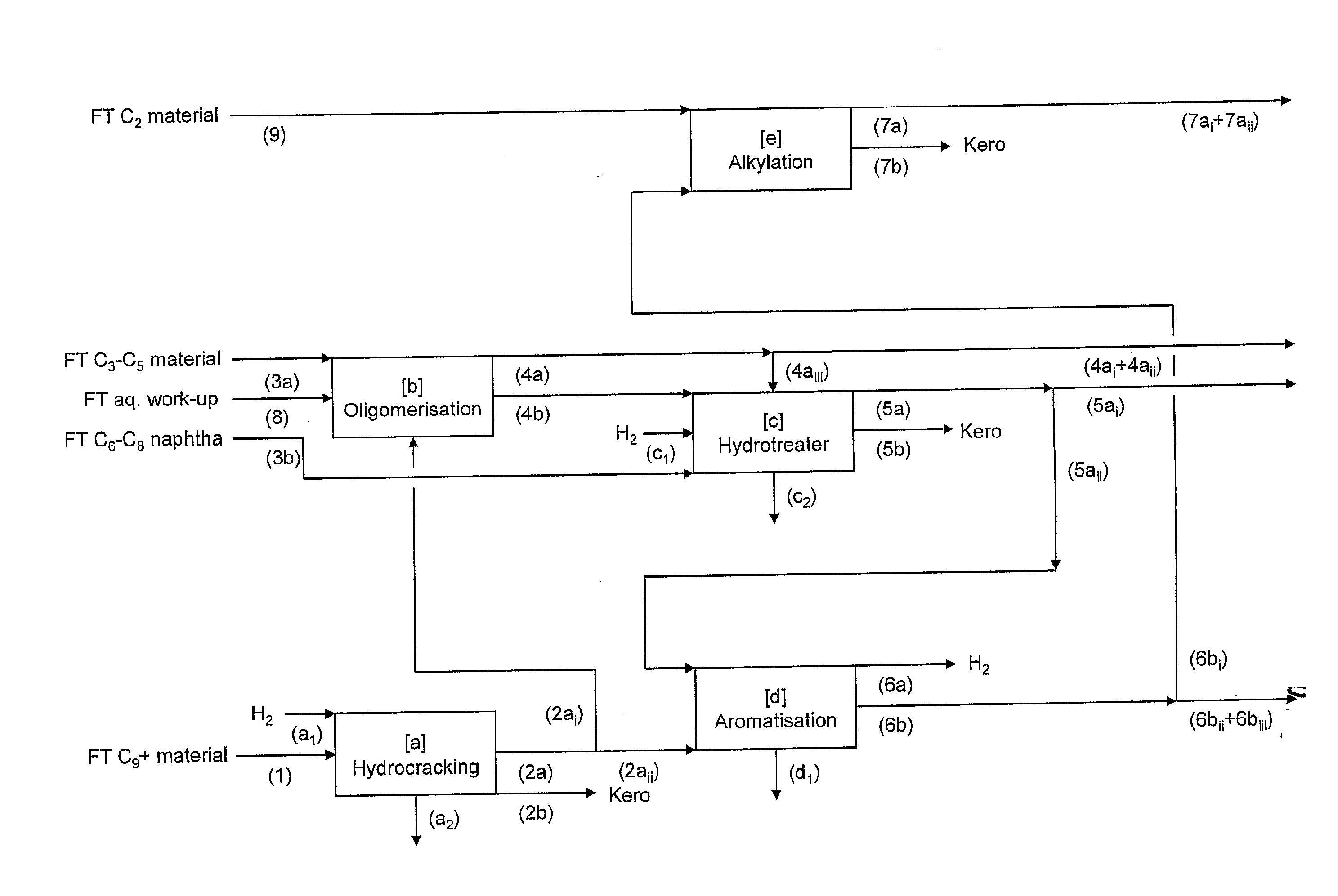

[0085]The jet fuel refinery design in this example and as shown in FIG. 3 is based on the same feed as Example 1. The difference lies in the selection of oligomerisation, aromatisation and alkylation processes. The aim of this example is to show that this invention is also capable of maximising jet fuel production, while meeting motor-gasoline specifications (Euro-4) for the naphtha. A further objective of this example is to illustrate how integration of the Fischer-Tropsch aqueous product work-up is beneficial.

[0086]The hydrocracker unit [a], which is operated in accordance with this invention, converts the Fischer-Tropsch C9 and heavier syncrude stream 1 to kerosene stream 2b and lighter products stream 2a. Only the C6-C8 fraction stream 2aii is routed to the aromatisation unit [d], while the C3-C5 fraction stream 2ai is routed to the oligomerisation unit [b] to be used as diluent for heat management.

[0087]The oligomerisation and alkylation conversion is combined in a single unit ...

example 3

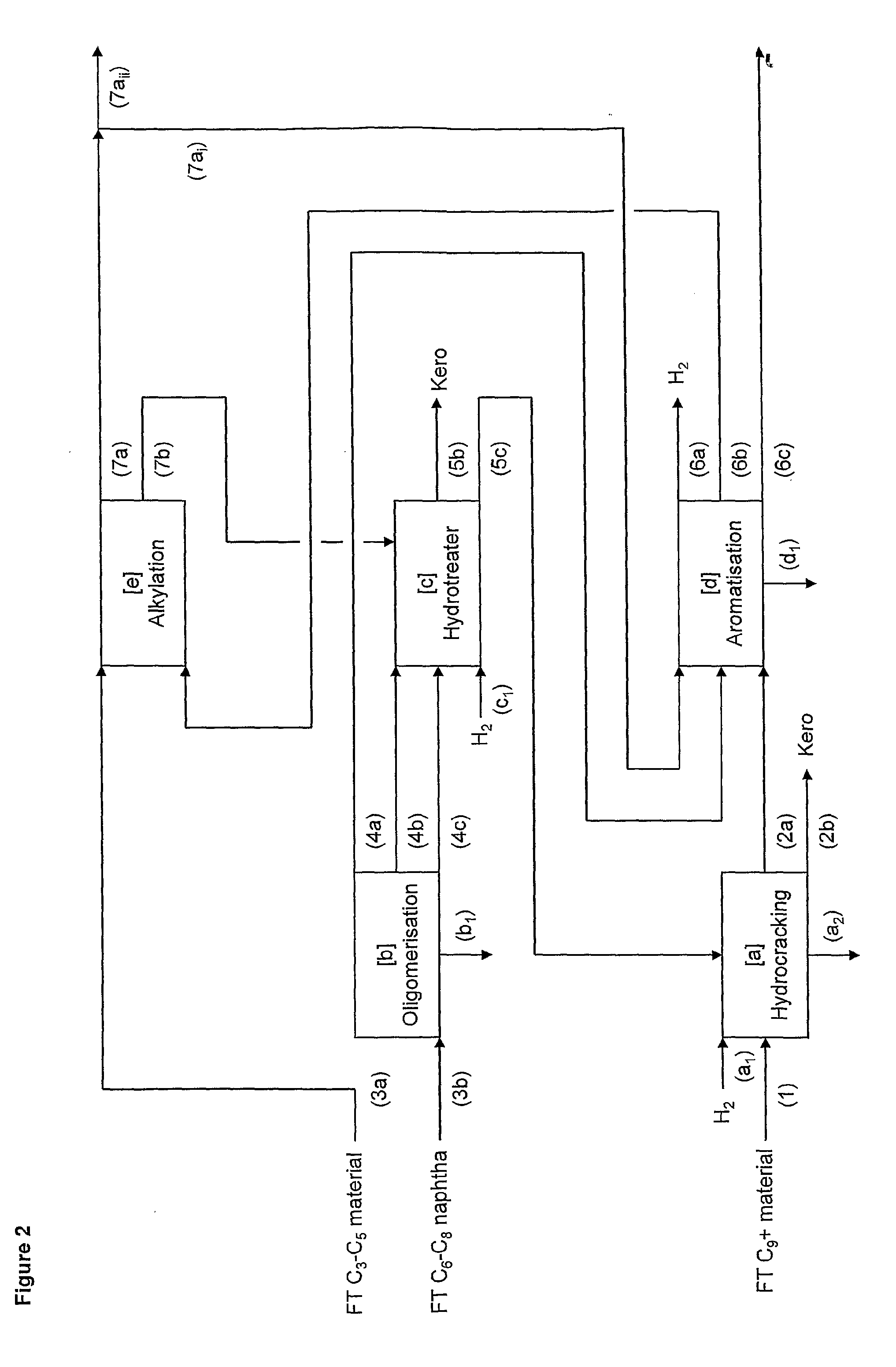

[0092]The jet fuel refinery design in Example 2 was modified by changing the way in which the aromatic alkylation is performed. In this example as shown in FIG. 4, a separate alkylation unit is used based on a zeolite catalyst, which is operated in such a way that the mono-alkylated aromatics are recycled to increase the yield of di-alkylated aromatics. Furthermore, ethylene has been selected as alkylating olefin to boost the overall yield of motor-gasoline and jet fuel on similar feed basis as Example 2, without significantly changing the motor-gasoline to jet fuel ratio.

[0093]The feeds, operation and products from the hydrocracker unit [a] is the same as in Example 2.

[0094]The oligomerisation unit [b], like in example 2, is based on a process using a SPA catalyst. The feeds are similar to that in Example 2, the only difference being that no aromatics are fed to this unit. The product is therefore not rich in alkyl aromatics, but consists mainly of aliphatic hydrocarbons. The produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com