Stirred Tank Reactor And Method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

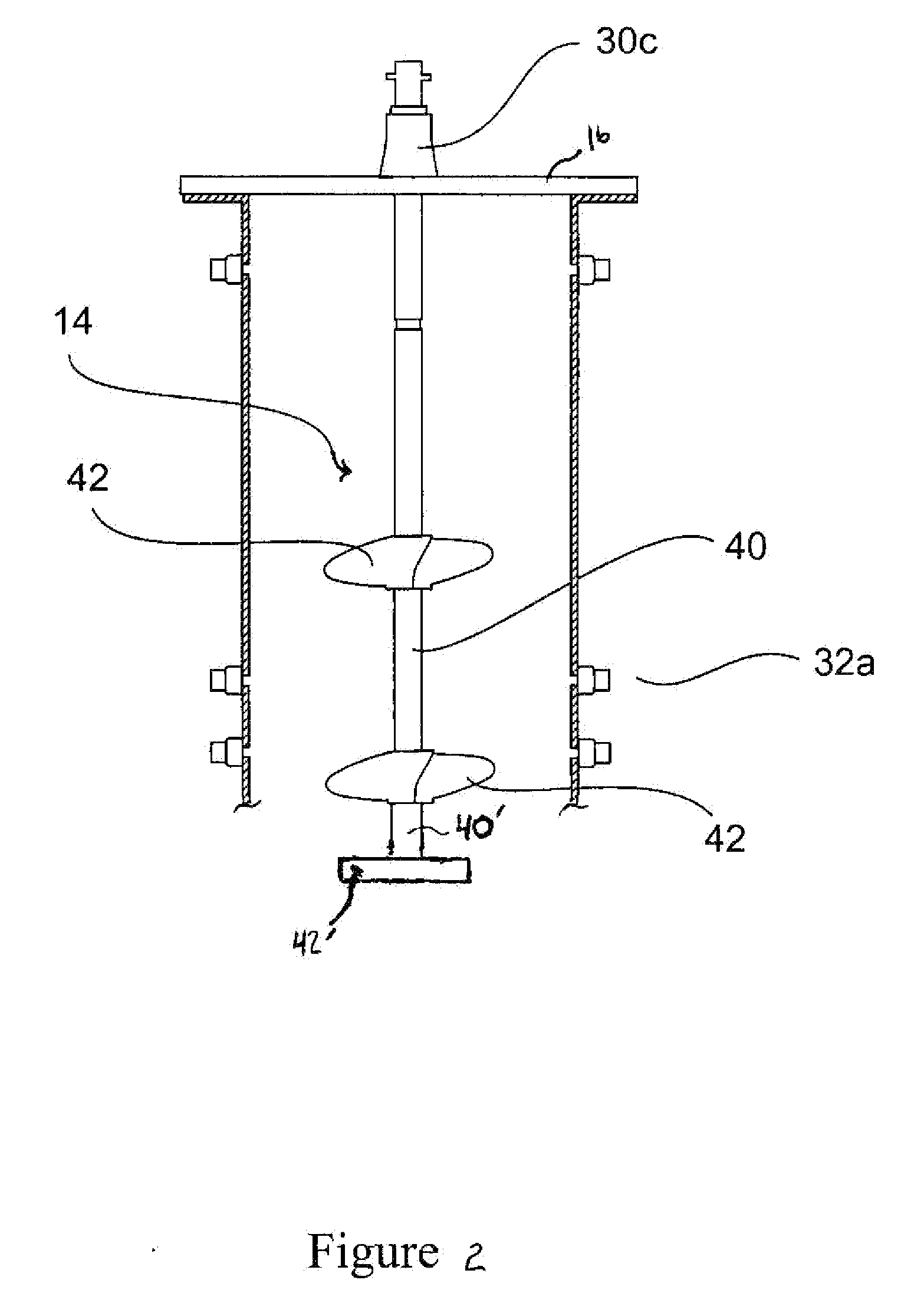

[0025]Suitable containers or housings useful here in useful herein are not particularly limited. For purposes of illustration, reactors, and in particular, bioreactors, will be discussed in detail, which include disposable as well as reusable bioreactors. For example, solvent-resistance bioreactors having a borosilicate glass cylinder and PTFE components, such as those commercially available from Millipore Corporation, can be used. Similarly, disposable bioreactors that utilize bags, or that are formed of semi-rigid or rigid molded plastic, can be used. Such disposable bioreactors are generally pre-sterilized. Means for agitation within the bioreactor is also not particularly limited, and includes impeller-based agitation, magnetic stirrers, as well as wave-induced agitation and agitation induced by gas bubbles. Agitation is important in preventing solids from settling and plugging the one or more membranes used for purification.

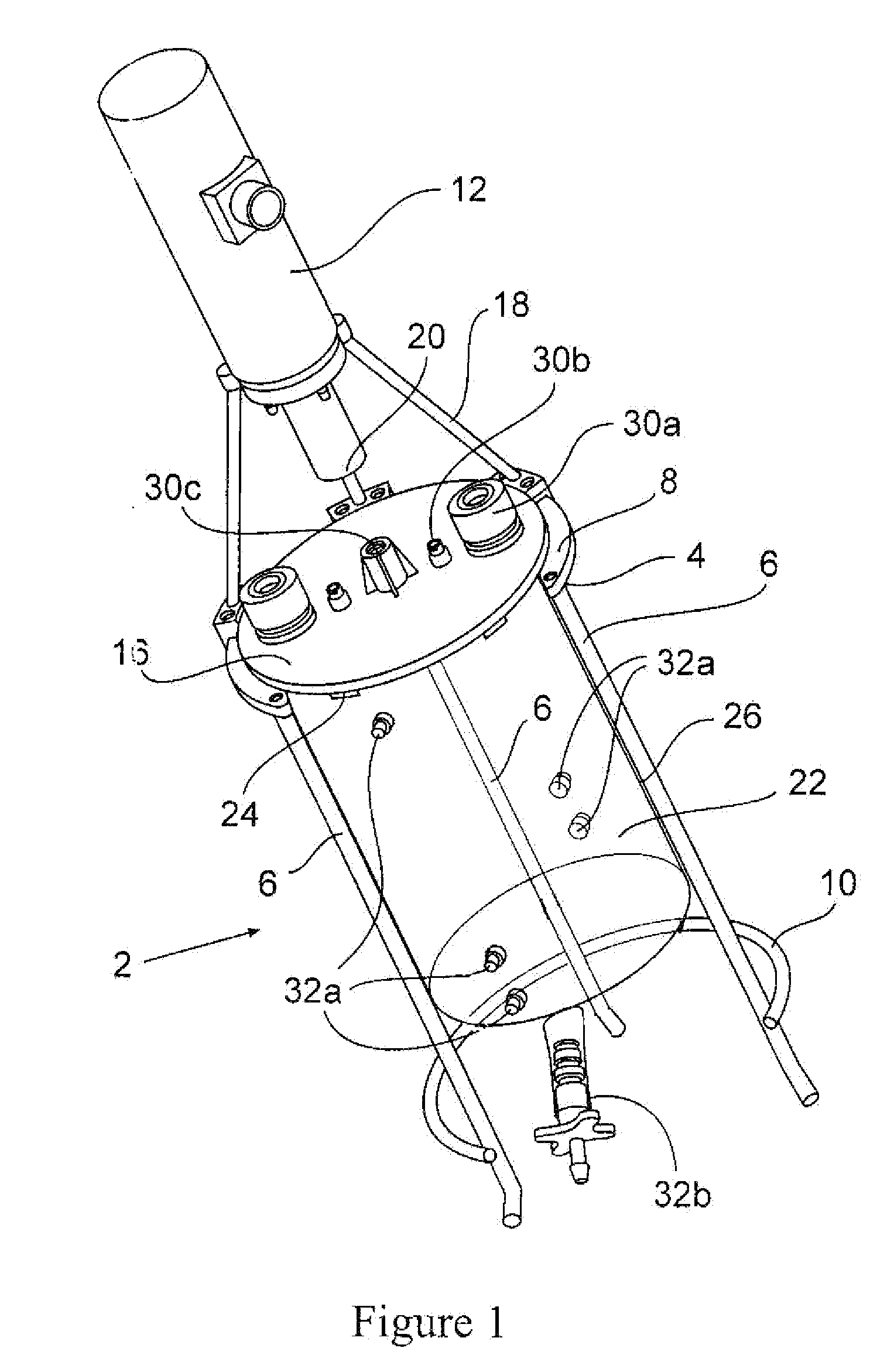

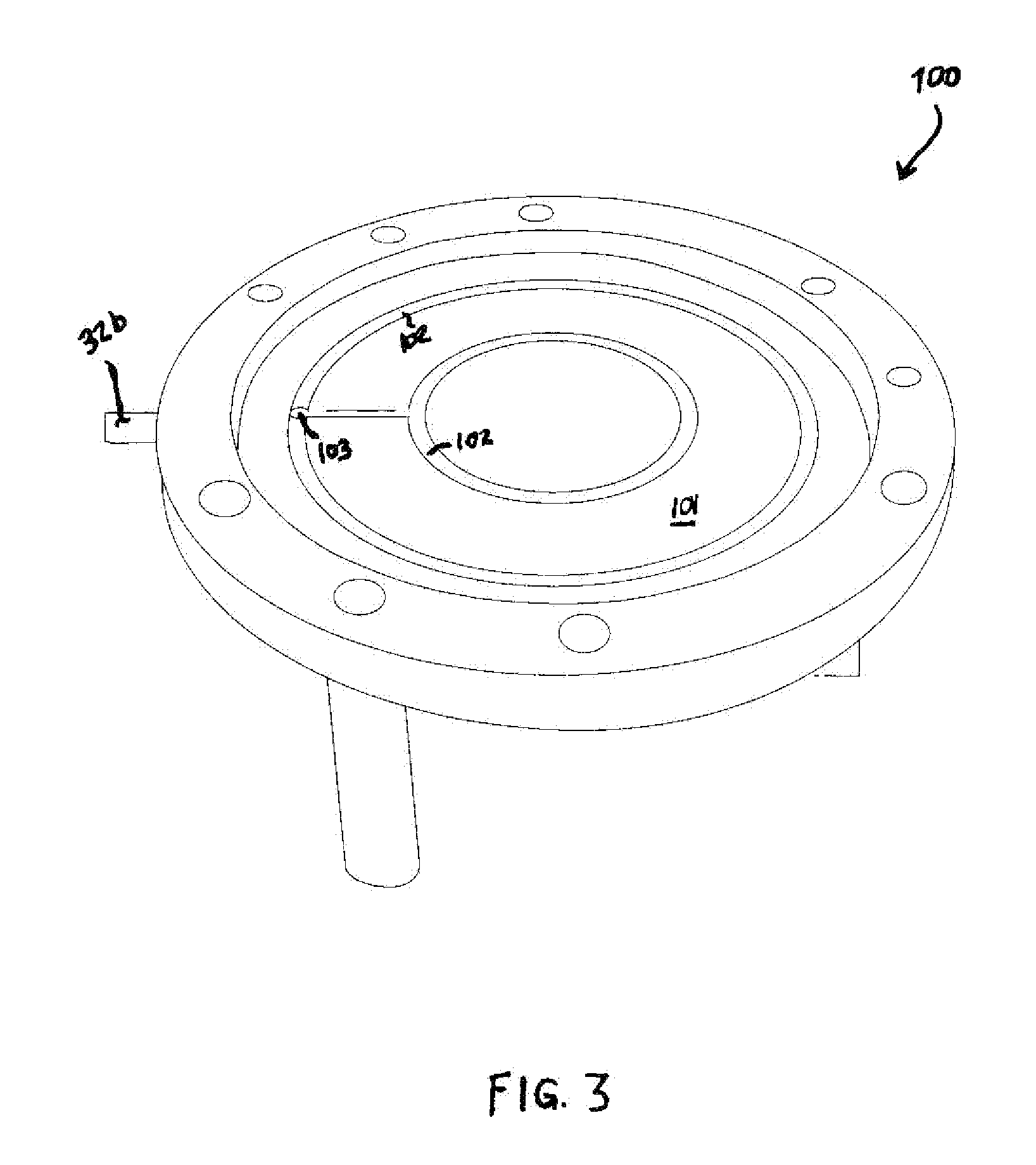

[0026]The following description is in reference to a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com