Field effect transistor manufacturing method

a manufacturing method and field effect technology, applied in the direction of basic electric elements, electrical equipment, semiconductor devices, etc., can solve the problems of difficult direct formation on resin substrates, which usually have a low thermal resistance, and achieve the effect of improving thermal insulation performance and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

o Post-Deposition

[0074]1-A The method for manufacturing a field effect transistor according to the present embodiment is characterized by, subsequent to preparing a substrate yet prior to forming on the substrate an active layer comprising an amorphous oxide, carrying out any of the following steps:

[0075]irradiating ultraviolet rays onto the substrate surface in an ozone atmosphere; or

[0076]irradiating plasma onto the substrate surface; or

[0077]cleaning the substrate surface with a chemical solution containing hydrogen peroxide; or

[0078]coating with a film comprising silicon and oxygen.

[0079]As a result of the above surface treatment process of the substrate, contaminants adhered to the substrate surface are removed, whereby the substrate surface is cleaned.

[0080]As a result of the above process, performance deterioration due to contaminants diffusing into the film constituting a TFT (thin-film transistor), or other such field effect transistor, can be reduced.

[0081]Further, as a re...

example 1-1

[0341]First, a PET substrate is placed in the chamber of a UV / O3 surface treatment apparatus, and the substrate surface is irradiated with ultraviolet rays.

[0342]The chamber that this apparatus has conducts deposition in an oxygen-containing atmosphere under atmospheric pressure. Ozone forms in the chamber from the ultraviolet ray irradiation. Contaminants on the substrate surface are removed by the ozone and the ultraviolet rays, whereby a clean surface can be obtained.

[0343]On a substrate which had undergone surface treatment using this method, an In—Ga—Zn—O system amorphous oxide semiconductor thin-film is deposited by pulsed laser deposition employing a KrF excimer laser with a polycrystalline sintered body having an InGaO3(ZnO)4 composition serving as the target.

[0344]The deposition conditions are appropriately set within the above-mentioned range.

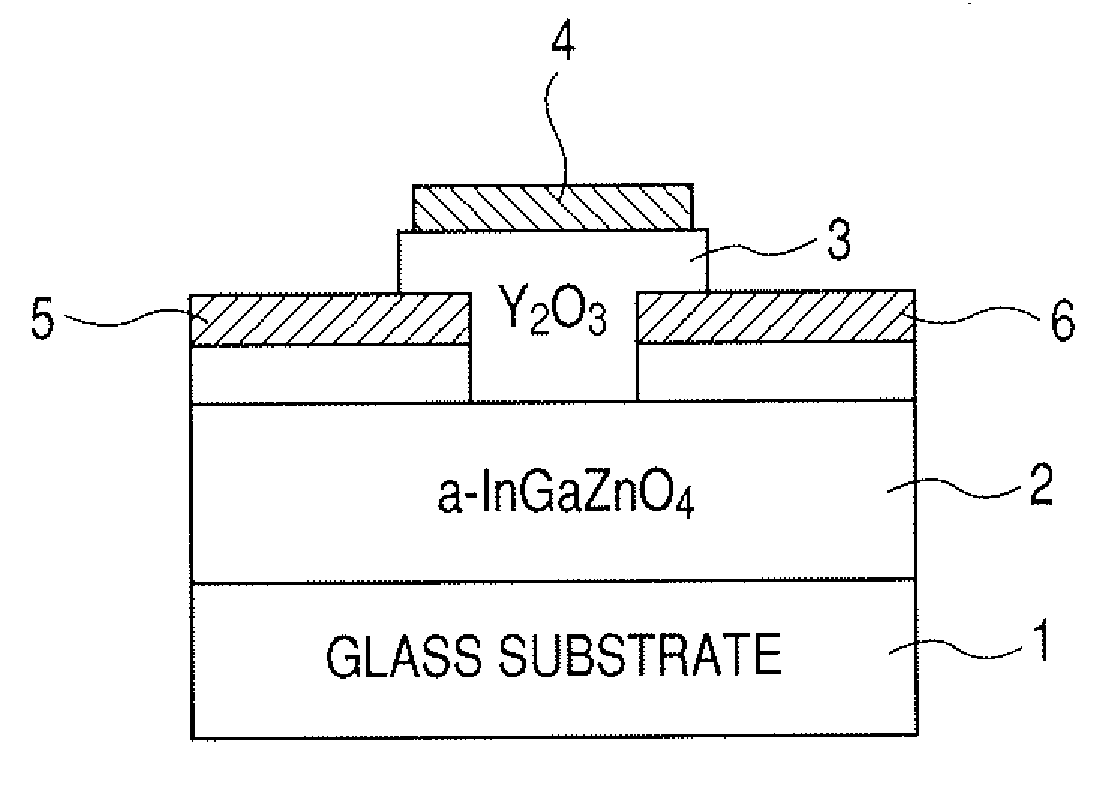

[0345]Next, the top-gate type MISFET device illustrated in FIG. 5 will be fabricated. Specifically, the device is fabricated in the ...

example 1-2

[0348]First, a glass substrate (1737, manufactured by Corning Incorporated) is placed in the chamber of a parallel-plate atmospheric-pressure plasma apparatus, and low-energy plasma is irradiated onto the substrate surface.

[0349]This apparatus removes contaminants on the substrate surface by irradiating low-energy plasma onto the substrate surface, whereby the state of the substrate top surface can be made to change.

[0350]On a substrate which had undergone surface treatment using this method, an In—Ga—Zn—O system amorphous oxide semiconductor thin-film is deposited by pulsed laser deposition employing a KrF excimer laser with a polycrystalline sintered body having an InGaO3(ZnO)4 composition serving as the target.

[0351]It can be confirmed from a peeling test carried out on the obtained amorphous oxide film that the adhesion between the substrate and the amorphous oxide film is extremely good.

[0352]An amorphous oxide obtained in this manner can be used to fabricate a transistor such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com