Magneto-caloric regenerator system and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

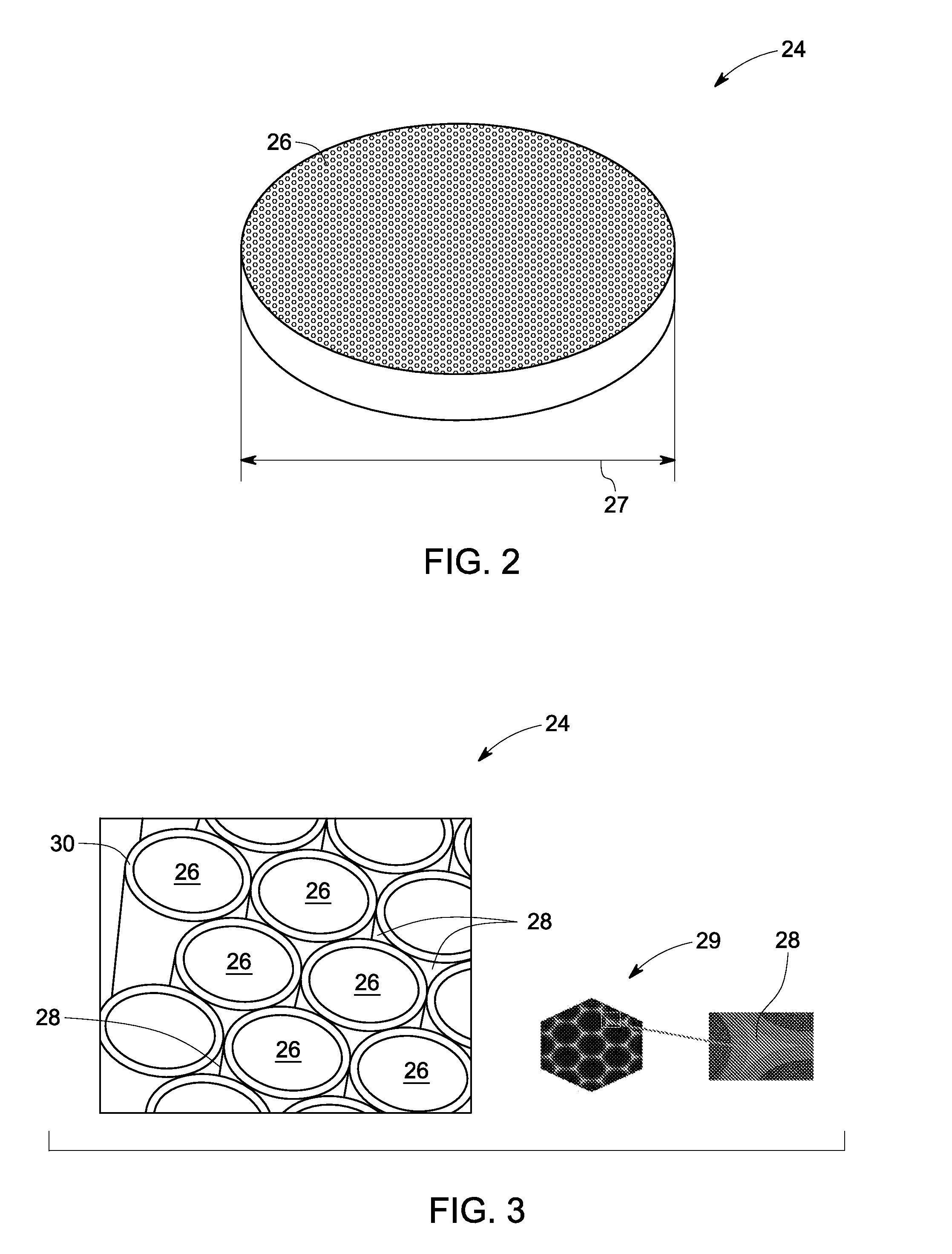

[0020]Typically, the magnetic-caloric system is based on the active magnetic regenerative (AMR) cycle. The AMR cycle implements magneto-caloric materials based heat exchangers often referred as regenerators for heat transfer between magneto-caloric material and a heat exchange fluid. Multiple layers of magneto-caloric material with different Curie temperature are used to achieve the temperature span. Regenerators would also include insulating layers between the stages to help maintain the thermal losses and hence the temperature gradient across regenerators. Embodiments disclosed herein, describes various aspects to design and fabrication of regenerators and magneto-caloric systems.

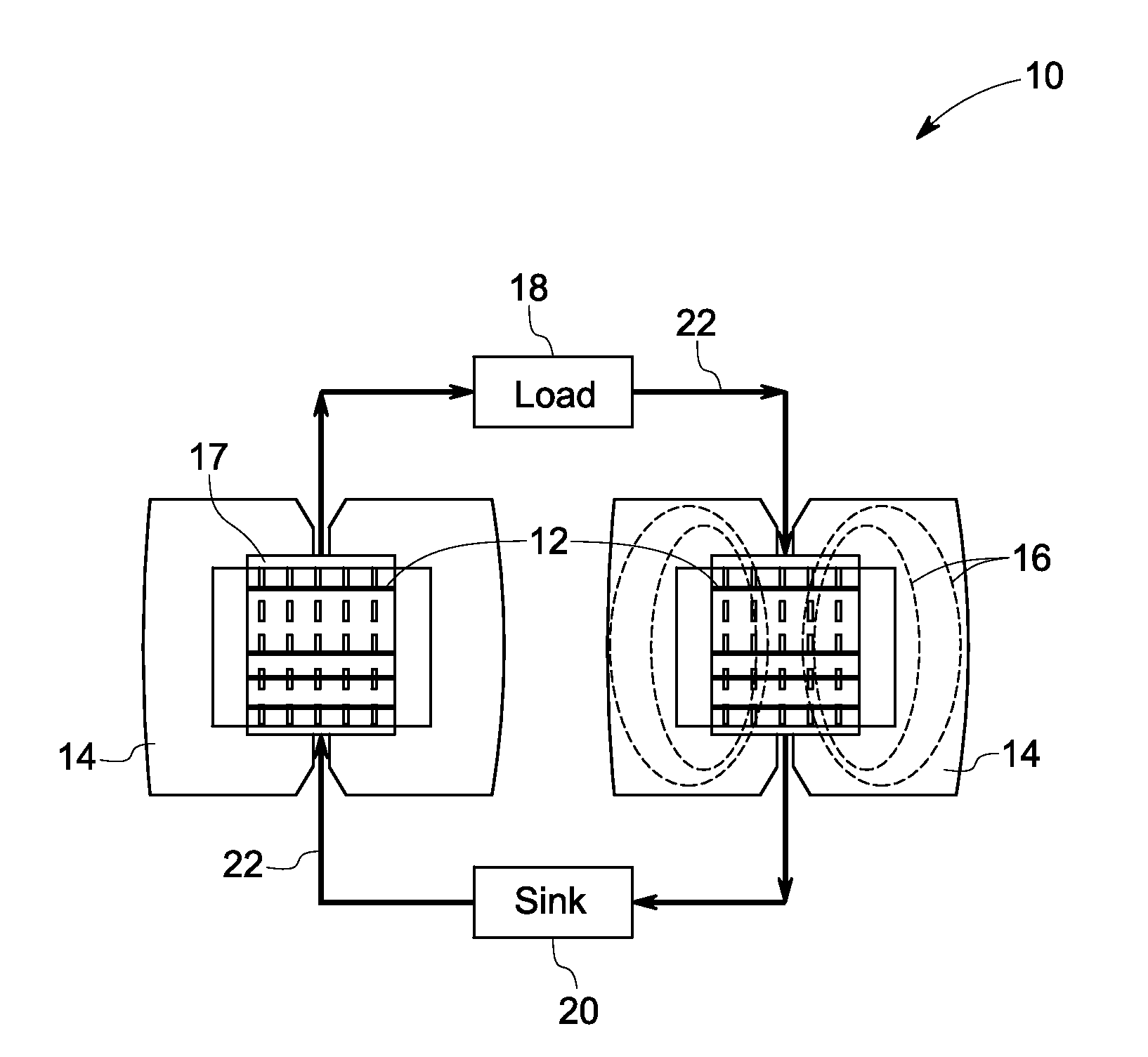

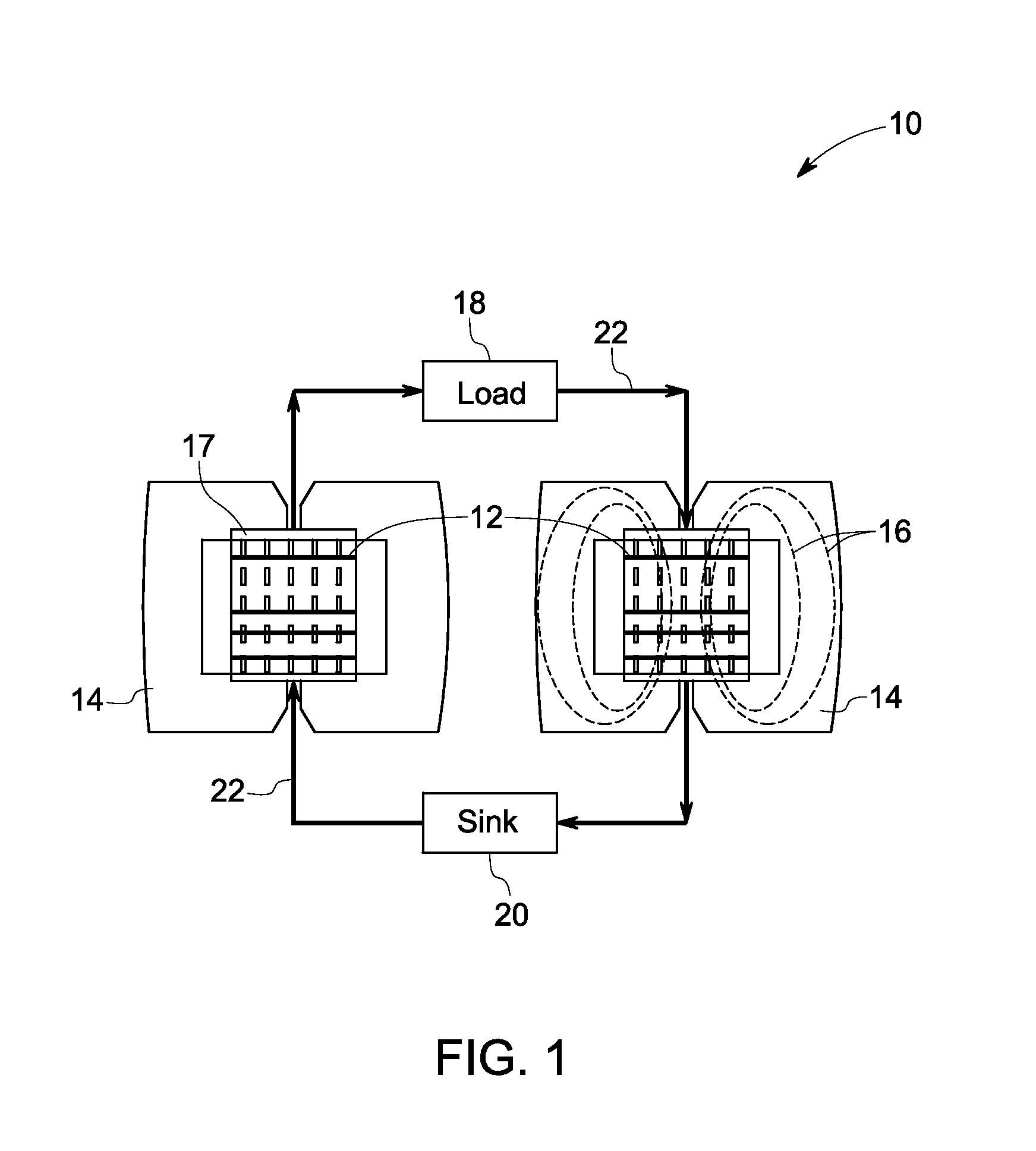

[0021]Referring now to the drawings, FIG. 1 illustrates an exemplary magneto-caloric refrigeration system 10 that is configured to provide cooling using the magneto-caloric effect. The system 10 includes a regenerator 17 having multiple magneto-caloric elements coupled thermally (represented by reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com