Solar cell structure

a solar cell and structure technology, applied in the direction of capacitors, solid-state devices, electrolytic capacitors, etc., can solve the problems of reducing the efficiency of solar cells, large loss of energy in heat, and heating of solar cells, and achieve the effect of improving the efficiency of transparent solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

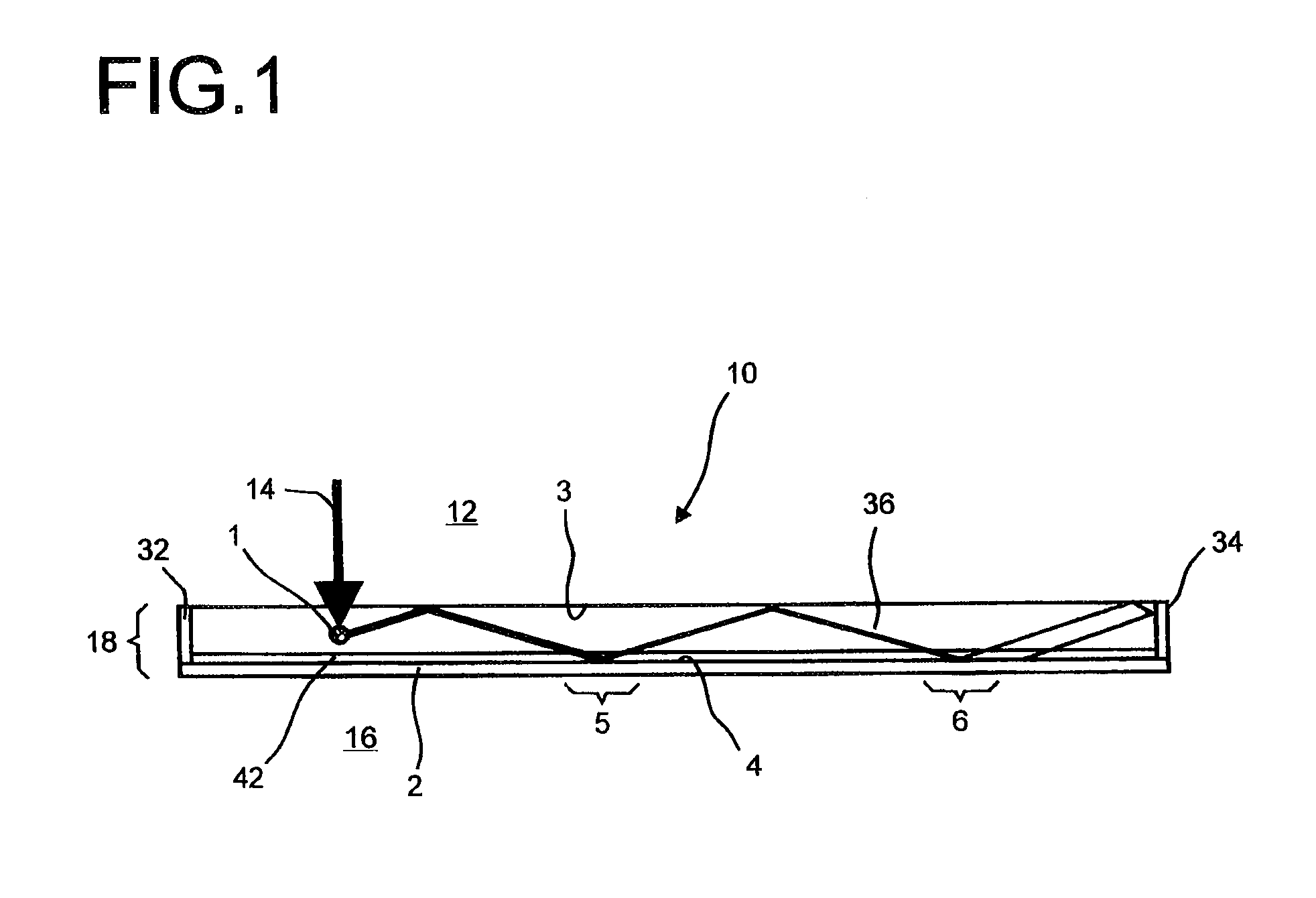

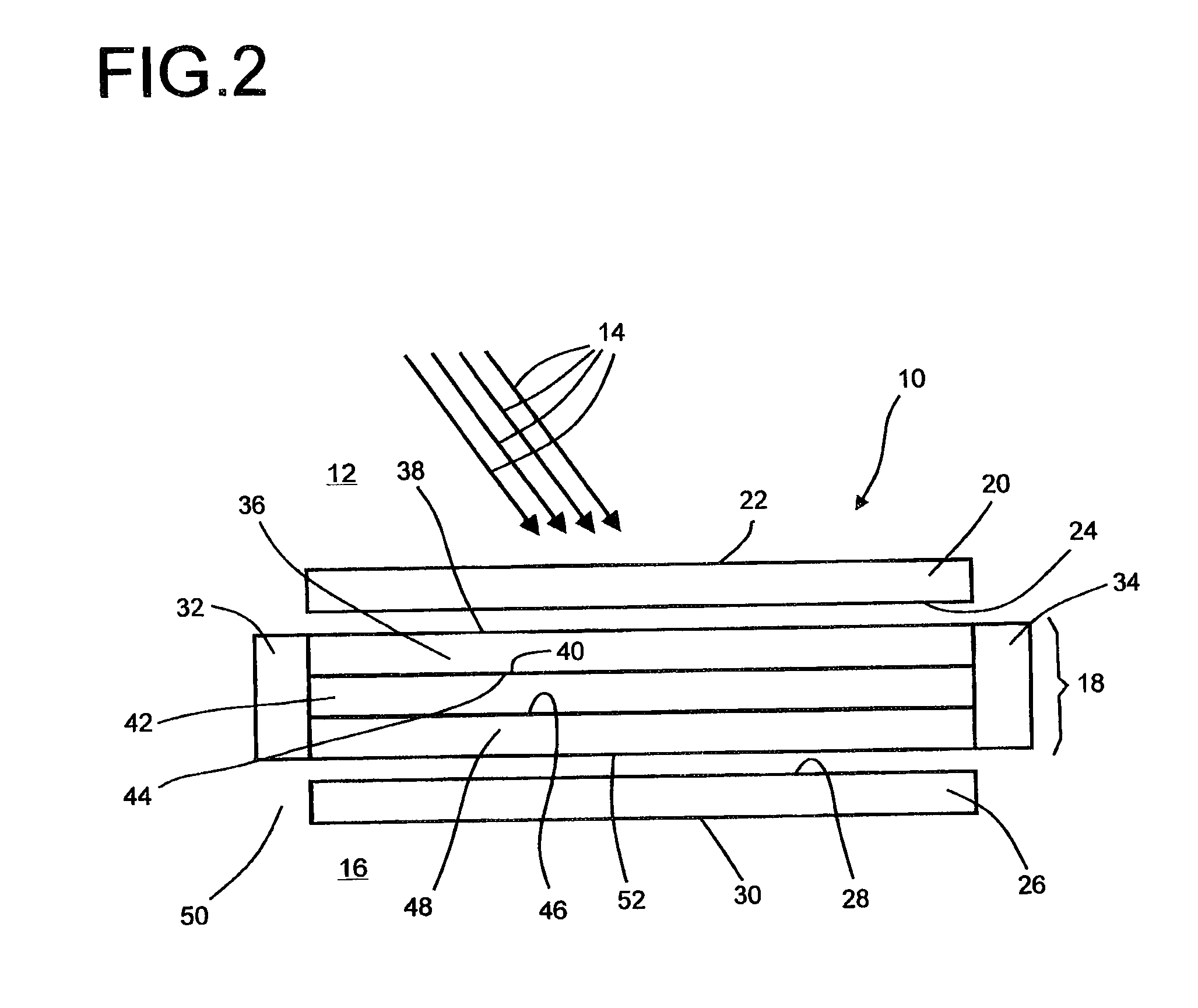

[0023]An alternative embodiment of the solar cell structure provided according to the invention can be found in the representation according to FIG. 1.

[0024]FIG. 1 shows a solar cell structure 10, which comprises a polymer layer. Below the polymer plate 36 there is a photovoltaic cell 42, underneath which a mirror surface 2 may in turn be arranged. Reference 14 denotes light incident on an illumination side 12, which strikes fluorescent molecules 1“dissolved” in a polymer layer 36. The incident light 14 is emitted by them in a stochastic distribution with a wavelength shift into all possible spatial directions. Only the part of this emitted light which is reflected, owing to total reflection at a first reflection surface 3 of the polymer layer 36, onto a second reflection surface 4 i.e. the upper side of the mirror surface 2, is of interest for the subsequent considerations. Besides the polymer layer 36, the solar cell structure 10 represented in FIG. 1—configured as a layer structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com