Surge-resistant and abrasion-resistant flexible insulating enamel

a flexible, abrasion-resistant technology, applied in the field of insulating enamel, can solve the problems of surge generation, surge transmission, surge generation of protection mechanism, etc., and achieve excellent abrasion resistance and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

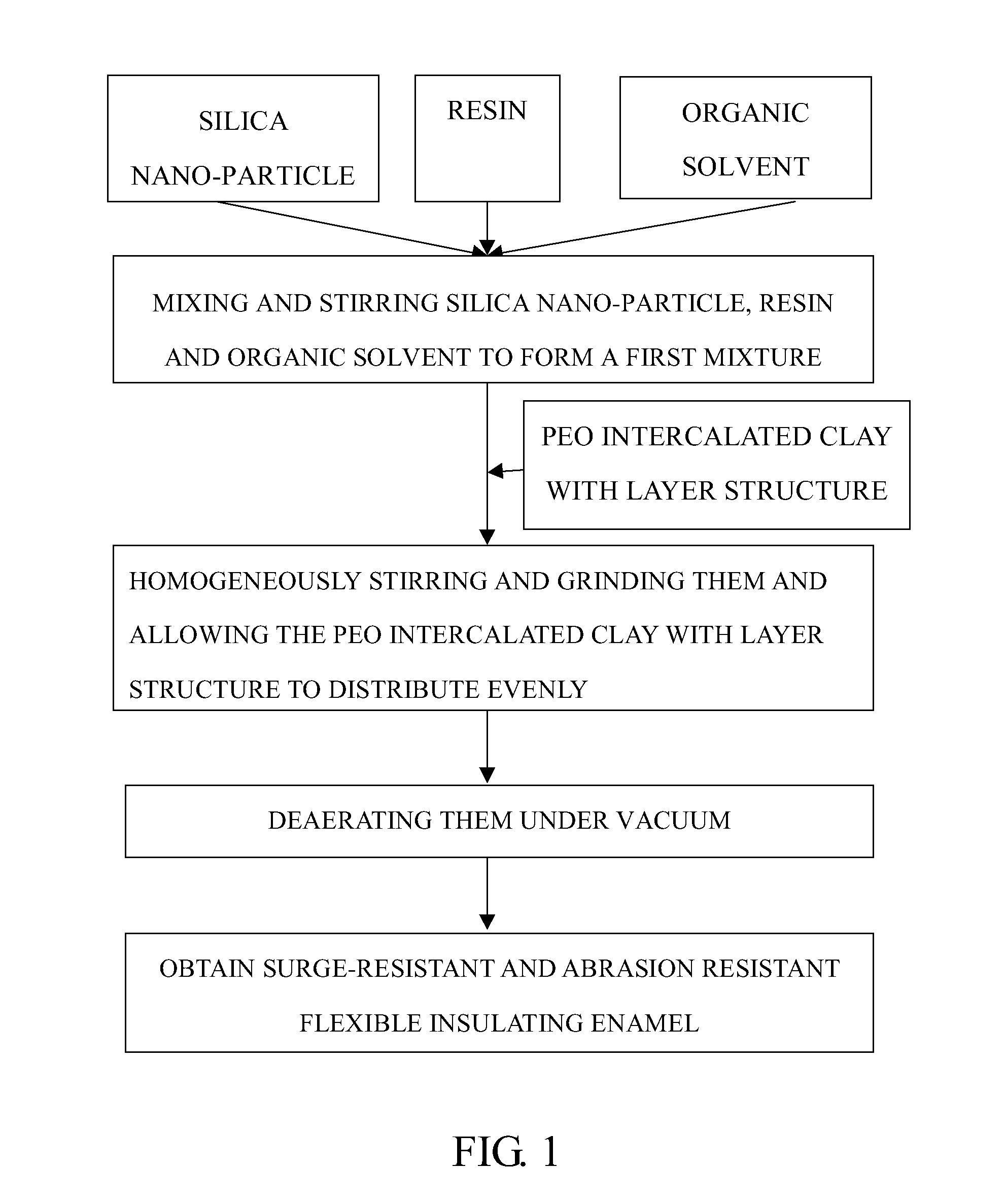

Method used

Image

Examples

example 1

[0030]950 g polyetherimide (PEI) solution (solid content: 40%, organic solution including 470 g cresol, 70 g NMP, 30 g xylene) and 10.0 g silica (SiO2) nano-particles were poured into a 1000-ml beaker and were stirred with high speed under room temperature for 30 minutes. 10.0 g PEO intercalated clay (Laponite RDS) was added into the 1000-ml beaker, wherein molecular weight of PEO is 100,000, a proportion of PEO and clay is 30:70. After being ground and dispersed, a mixture in the 1000-ml beaker was deaerated under vacuum for 30 minutes to obtain a surge-resistant and abrasion resistant flexible insulating enamel of the present invention.

example 2

[0031]800 g polyetherimide (PEI) solution (solid content: 40%, organic solution including 380 g cresol, 70 g NMP, 30 g xylene) and 79.6 g silica (SiO2) nano-particles were poured into a 1000-ml beaker and were stirred with high speed under room temperature for 30 minutes. 0.4 g PEO intercalated clay (Laponite RDS) was added into the 1000-ml beaker, wherein molecular weight of PEO is 100,000, a proportion of PEO and clay is 30:70. After being ground and dispersed, a mixture in the 1000-ml beaker was deaerated under vacuum for 30 minutes to obtain a surge-resistant and abrasion resistant flexible insulating enamel of the present invention.

example 3

[0032]750 g polyetherimide (PEI) solution (solid content: 40%, organic solution including 350 g cresol, 70 g NMP, 30 g xylene) and 60.0 g silica (SiO2) nano-particles were poured into a 1000-ml beaker and were stirred with high speed under room temperature for 30 minutes. 40.0 g PEO intercalated clay (Laponite RDS) was added into the 1000-ml beaker, wherein molecular weight of PEO is 100,000, a proportion of PEO and clay is 30:70. After being ground and dispersed, a mixture in the 1000-ml beaker was deaerated under vacuum for 30 minutes to obtain a surge-resistant and abrasion resistant flexible insulating enamel of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com