Method and System for Sootblower Flow Analyzer

a flow analyzer and flow filter technology, applied in the direction of machines/engines, flushing, lighting and heating apparatus, etc., can solve the problems of increasing the risk of tube erosion, reducing the efficiency of boilers, and reducing the efficiency of sootblowing processes, so as to improve the efficiency of sootblowing process and the boiler availability rating, reduce the number of leakage of tubes, and improve the effect of the net plant heat ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]For a fuller understanding of the nature and objects of the present invention, reference should be made to the following detailed description taken in connection with the accompanying drawings, wherein:

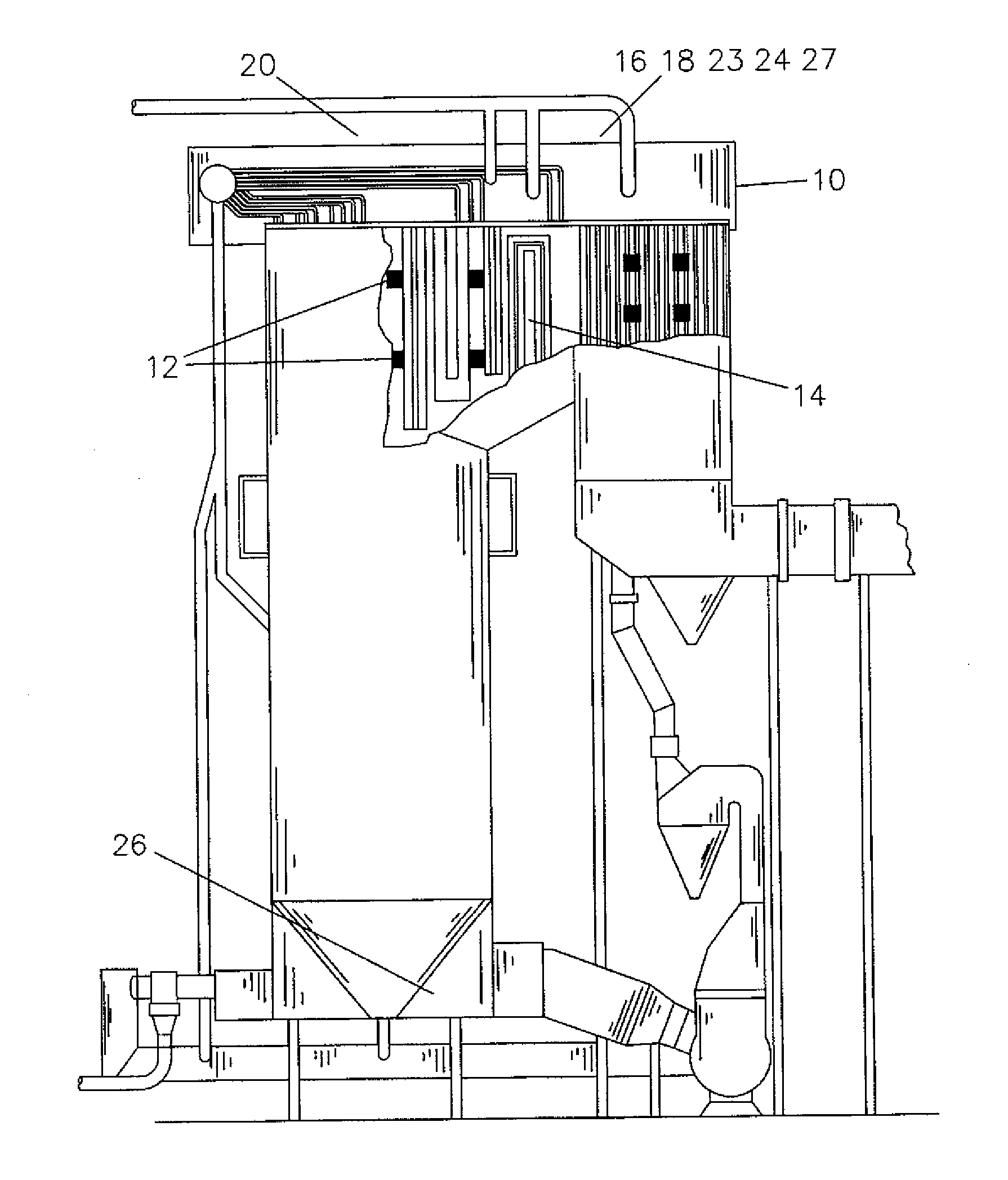

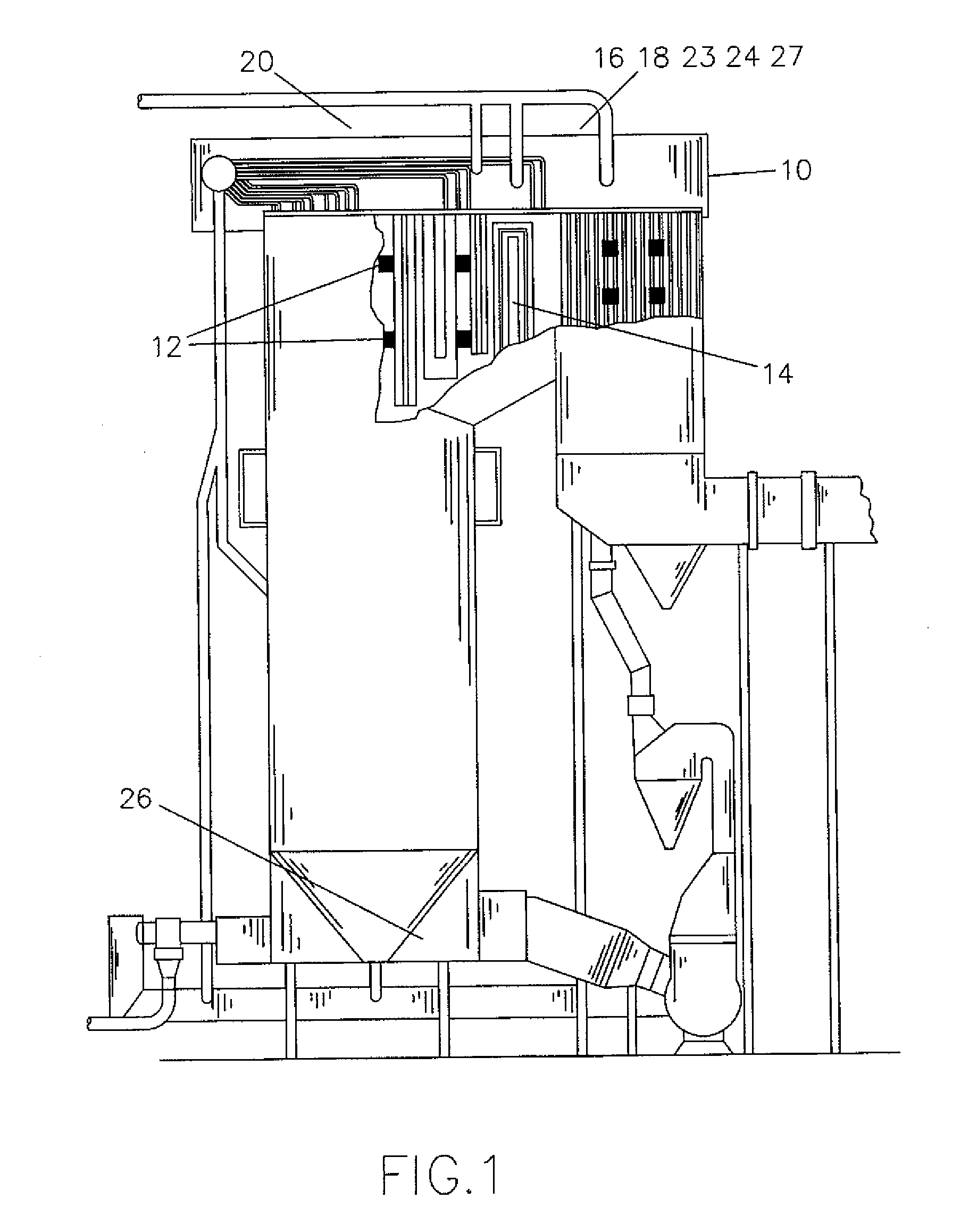

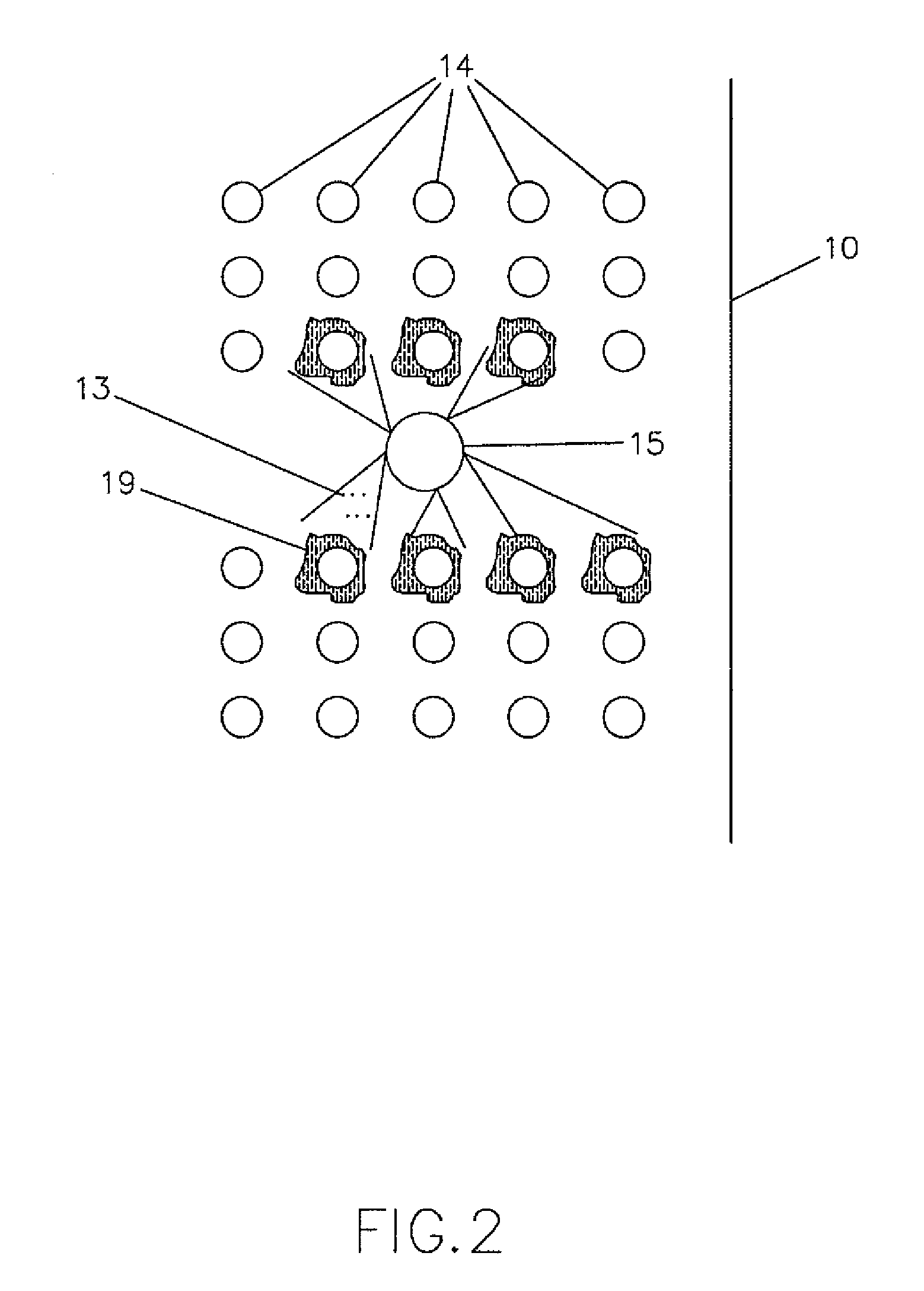

[0022]FIG. 1 is drawing of a power plant boiler 10 with portions broken away to show the heat exchanger tubes 14 within the power plant boiler 10 which are to be cleaned by sootblowers 12. Attached to the cleaning medium line 20 is a mass flow measurement device 16 and a temperature measuring device 18 installed upstream. The mass flow measurement device 16 includes flow transmitter 23. The temperature measuring device 18 includes a temperature transmitter 24. The steam pressure measuring device 27 of the cleaning medium is measured upstream of the cleaning medium line 20. The physical drain valves 26 are shown located at the system low point for automatic removal of the cleaning medium, for example for steam then water is removed. For leak testing, the physical drain valves 26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com