Heat treatment method of znte single crystal substrate and znte single crystal substrate

a single crystal substrate and heat treatment technology, applied in the direction of crystal growth process, polycrystalline material growth, after treatment details, etc., can solve the problems of high te, low light transmission of znte single crystal substrate, and difficulty in growing bulk crystals by traditional manufacture techniques. , to achieve the effect of reducing the temperature of the substrate, high light transmission, and superior characteristi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]Hereinafter, a preferred embodiment of the present invention will be described.

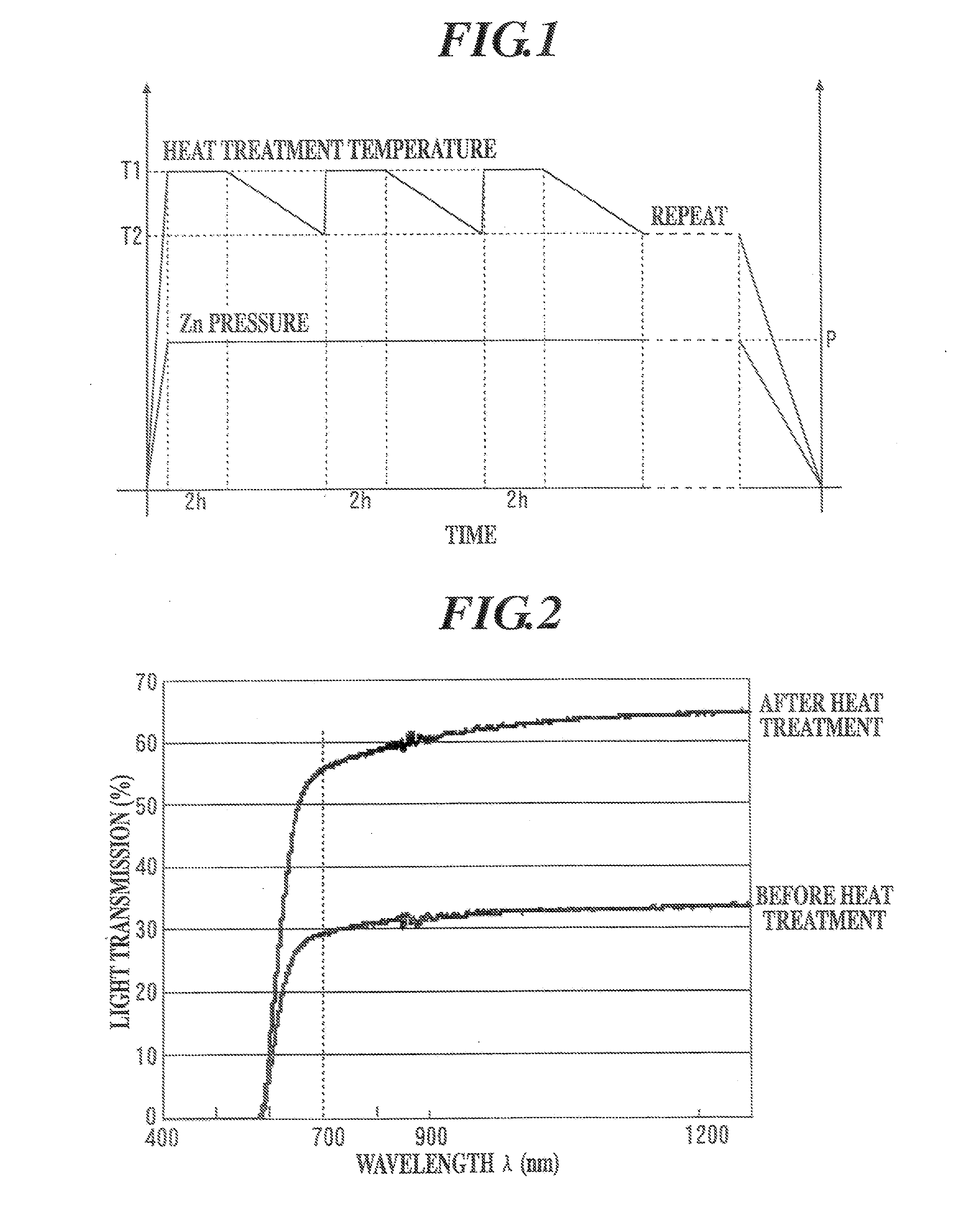

[0035]In this embodiment, a sample obtained by the following method (substrate) was used. A ZnTe single crystal substrate having a diameter of 2 to 3 inches and having a plane orientation of (100) or (110) was obtained by a melt growth using gallium (Ga) as a dopant. The obtained substrate is sliced so as to have a thickness of 0.7 to 4.0 mm. The wrapping using #1200 abrasive grain and the etching using Br23% MeOH were carried out for the surface of the sliced substrate to use it as the sample (substrate).

[0036]Before the heat treatment for the ZnTe single crystal substrate, the ZnTe single crystal substrate and Zn were placed at a predetermined position in a quartz ampule and the ampule was sealed at a vacuum degree of 1.0 Pa or less. Then, the quartz ampule was placed in a diffusion furnace to perform the following heat treatment.

[0037]The heat treatment according to this embodiment was performed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sizes | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com