Methods and apparatus for carbon dioxide-oxygen-coal combustion

a technology of carbon dioxide and coal combustion, which is applied in the direction of indirect carbon-dioxide mitigation, combustion types, lighting and heating apparatus, etc., can solve the problems of reduced flame speed, increased fire hazards in coal grinding mills, and reduced flame speed, so as to achieve better combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

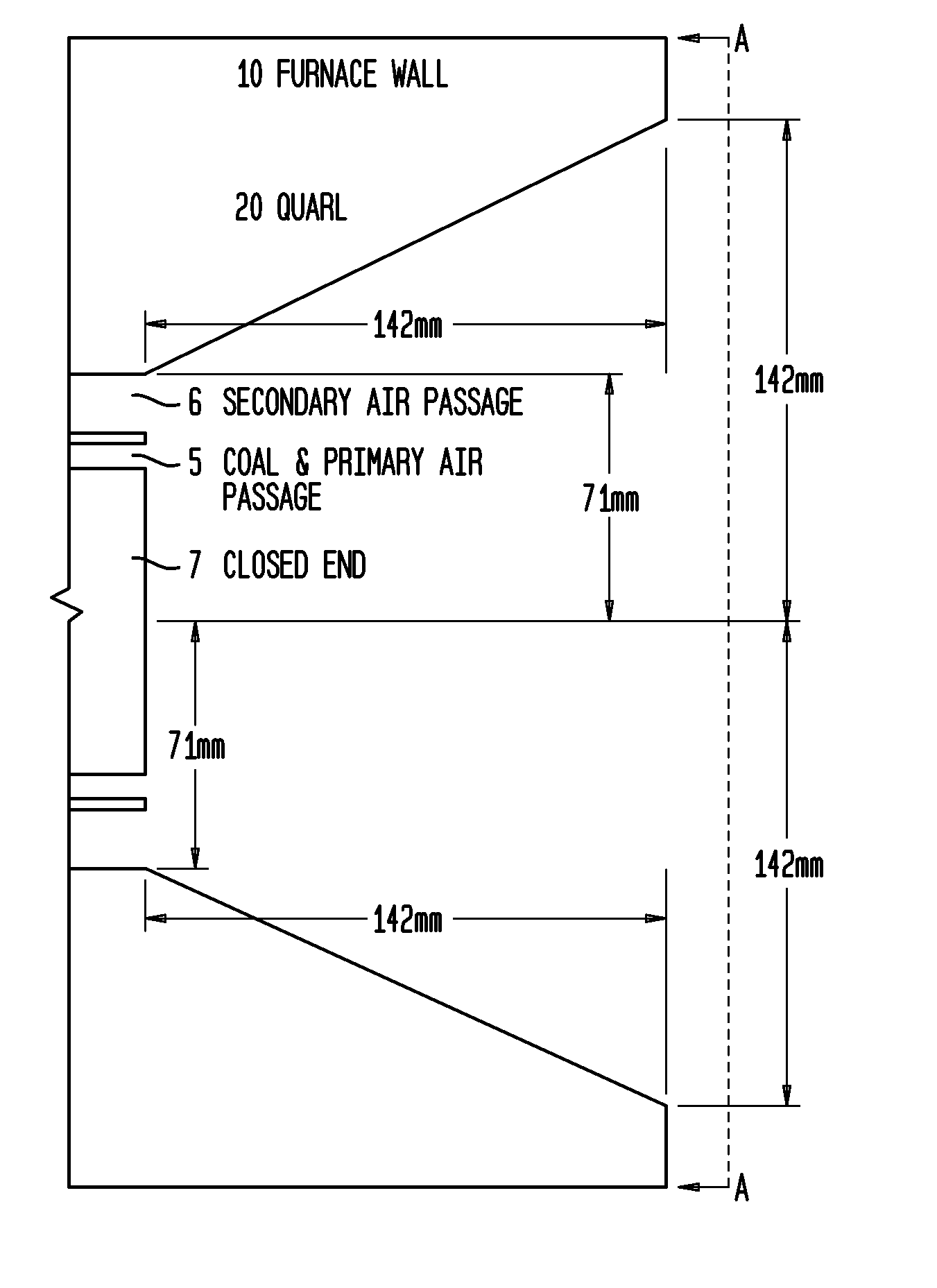

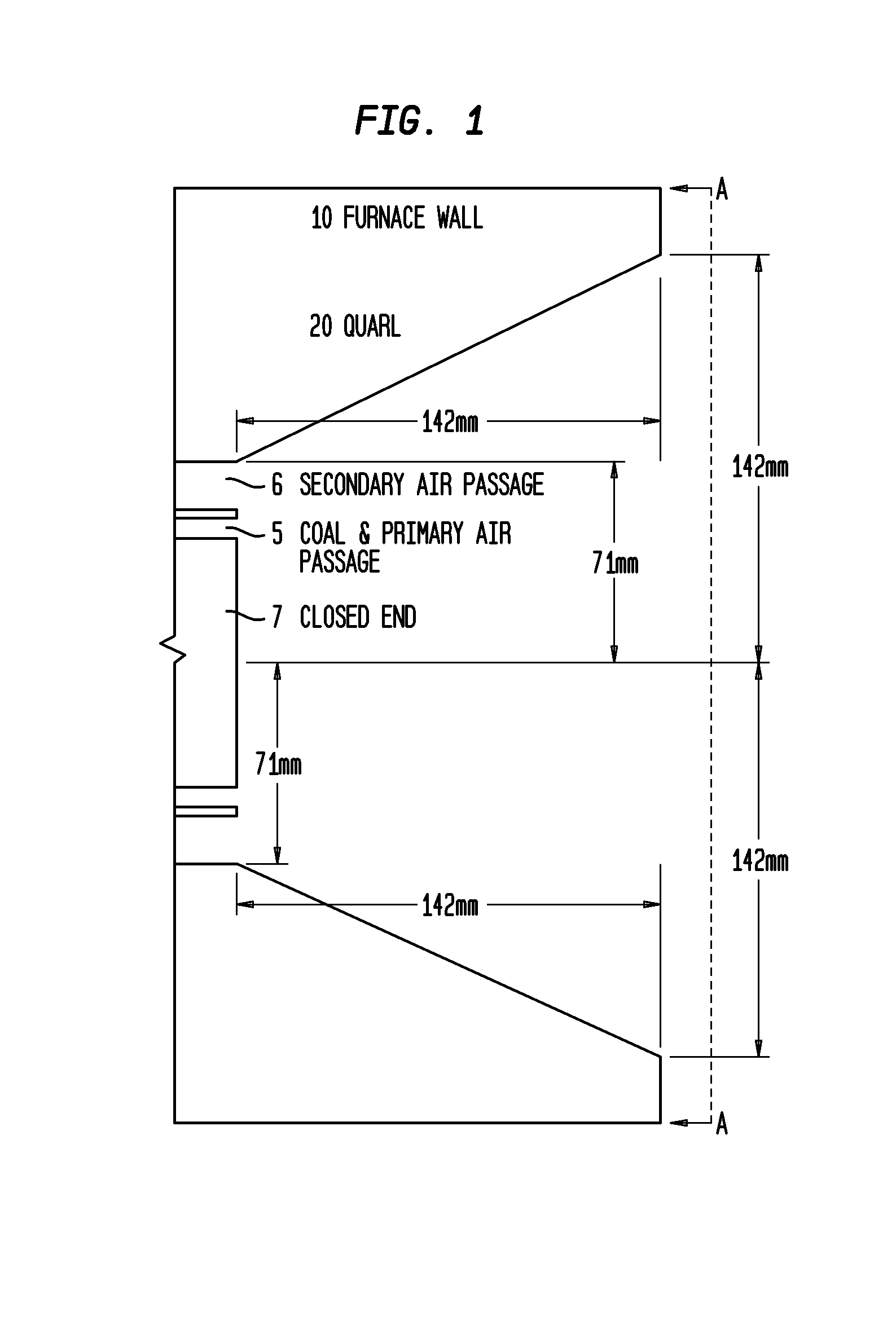

[0025]FIG. 1 and FIG. 2 show an air-coal burner. The air-coal burner is typically round in shape as seen in FIG. 2. Viewing the air-coal burner from the side as in FIG. 1 shows a furnace wall 10 at the top and bottom which surrounds the air-coal burner. The air-coal burner comprises a quarl 20 which surrounds the closed end 7 of the air-coal burner. There are two openings, the first being the secondary air passage 6 which will concentrically surround the second opening, coal and primary air passage 5.

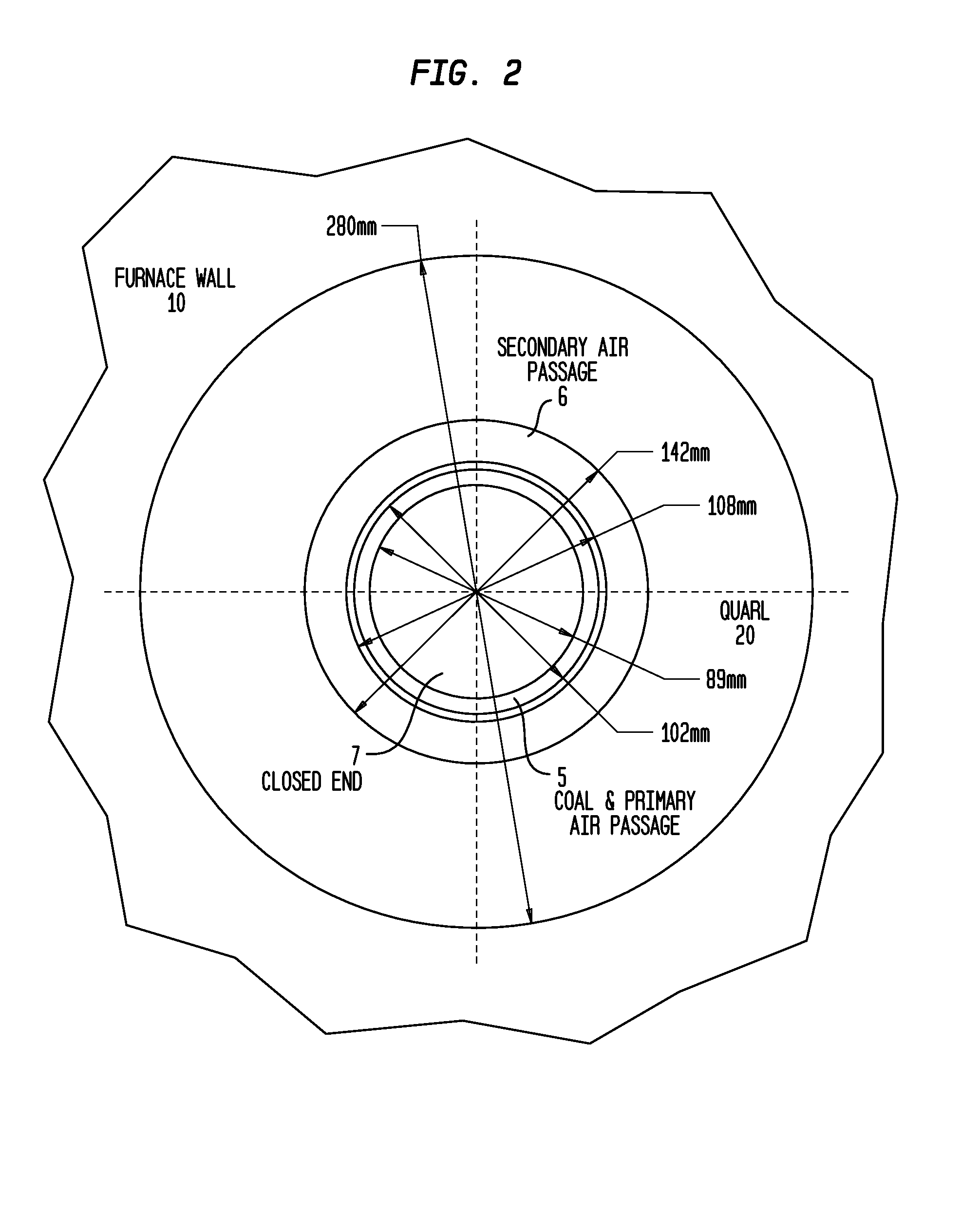

[0026]FIG. 2 shows the air-coal burner of FIG. 1 along the A-A axis and proffers a view of the air-coal burner from its end. The furnace wall 10 is shown surrounding the quarl 20 which has two openings in its middle. The first opening is the secondary air passage 6 which concentrically surrounds the second opening, the coal and primary air passage 5. Both these passages concentrically surround the closed end 7 of the air-coal burner.

[0027]FIG. 3 shows the air-coal burner with oxidant la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com