In-situ microbial oxygen generation and hydrocarbon conversion in a hydrocarbon containing formation

a hydrocarbon containing, in-situ oxygen technology, applied in the direction of fermentation, fluid removal, borehole/well accessories, etc., can solve the problems of hampered utilization of microorganisms to enhance hydrocarbon recovery, and achieve enhanced hydrocarbon recovery, improved quality, and enhanced bioavailability and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

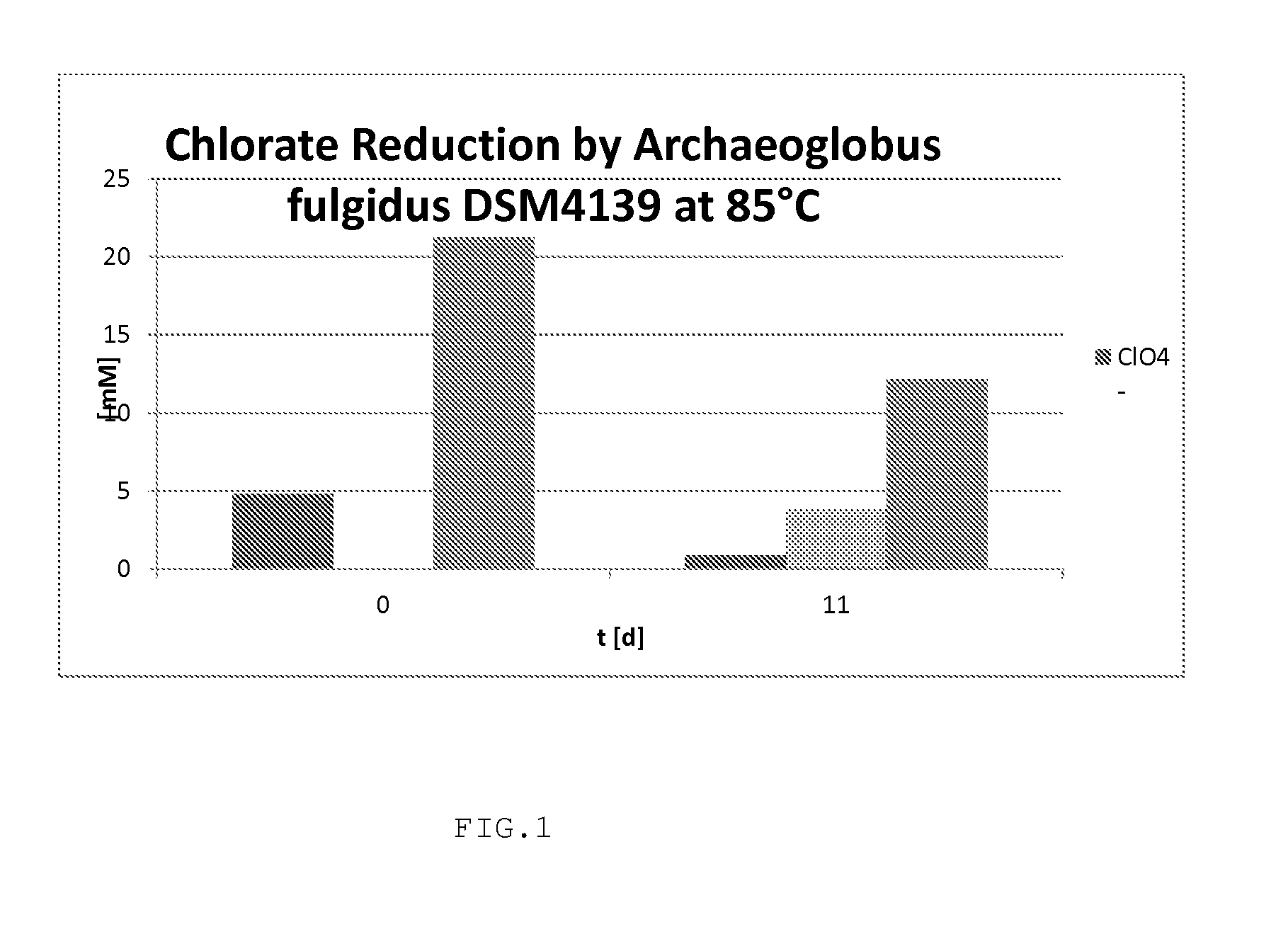

Image

Examples

example

[0050]A suitable embodiment of the method according to the invention, comprises the following steps:

a) Screening whether a target underground crude oil and / or natural gas containing reservoir formation has features, such as temperature, salinity, heterogeneity, oil characteristics, micro-organisms, volatile fatty acids, hydrogen ions, acetate, propionate or butyrate and / or other potential electron donors, etc., which allow use of the method according to the invention;

b) Analyzing the composition of the water, oil and / or natural gas in the formation, for example by screening a sample taken from the formation;

c) Identification of potentially interesting micro-organisms with molecular DNA technologies using either general (16S rRNA-related) primer sets or enzyme / functional group specific primer sets (nitrate / nitrite-reductase, (per)chlorate reductases, chlorite dismutase, or hydrocarbon (alkane) degrading enzymes or using metagenomics;

d) Isolation of potentially interesting indigenous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com