Graphene conjugate fiber and method for manufacturing same

a graphene and conjugate technology, applied in the field of flexible graphene composite fibers, can solve the problems of limiting the maximum mechanical properties of graphene, and achieve the effect of superior mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example1

Preparation of Solution of Graphene (RCCG) Chemically Converted by Reduction

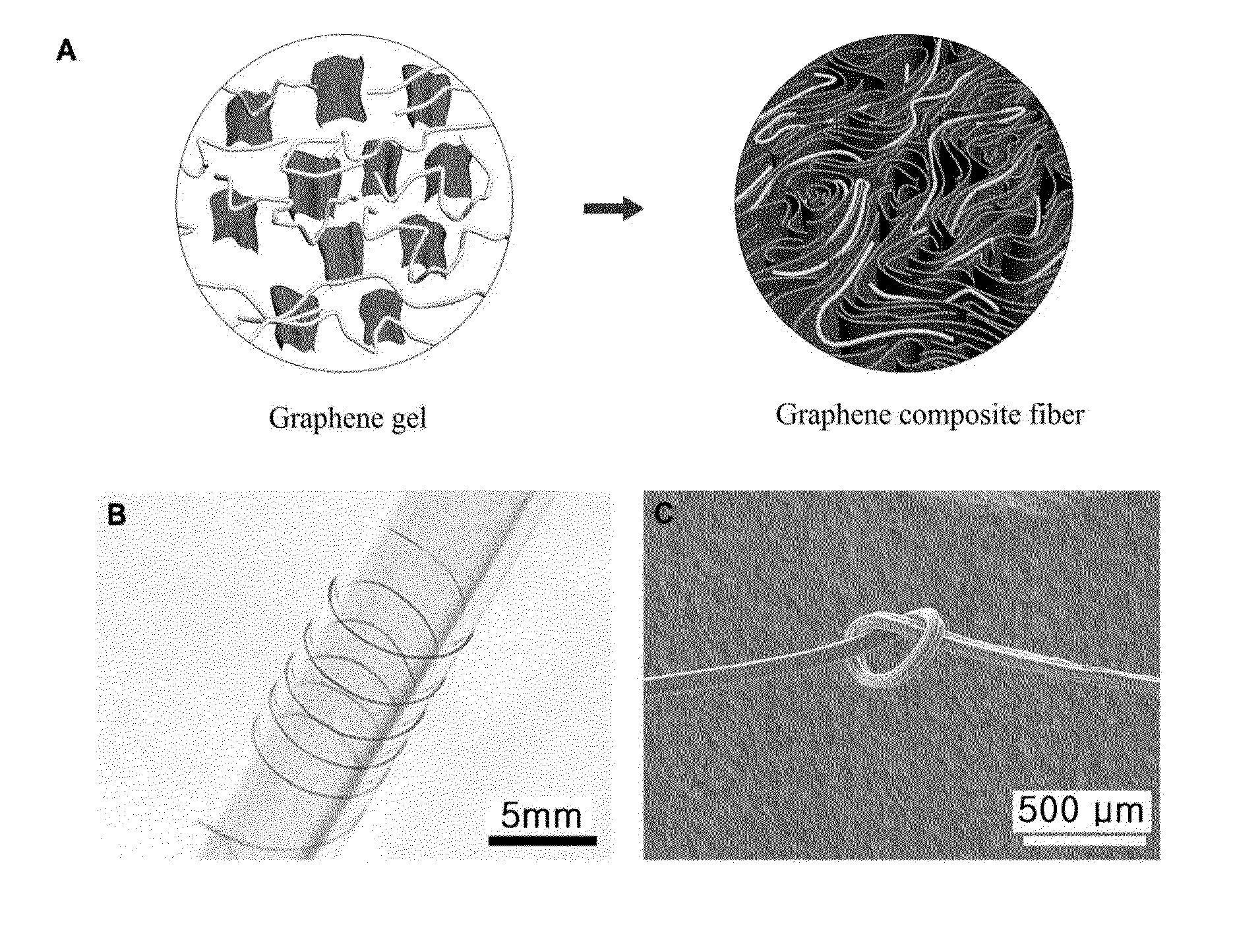

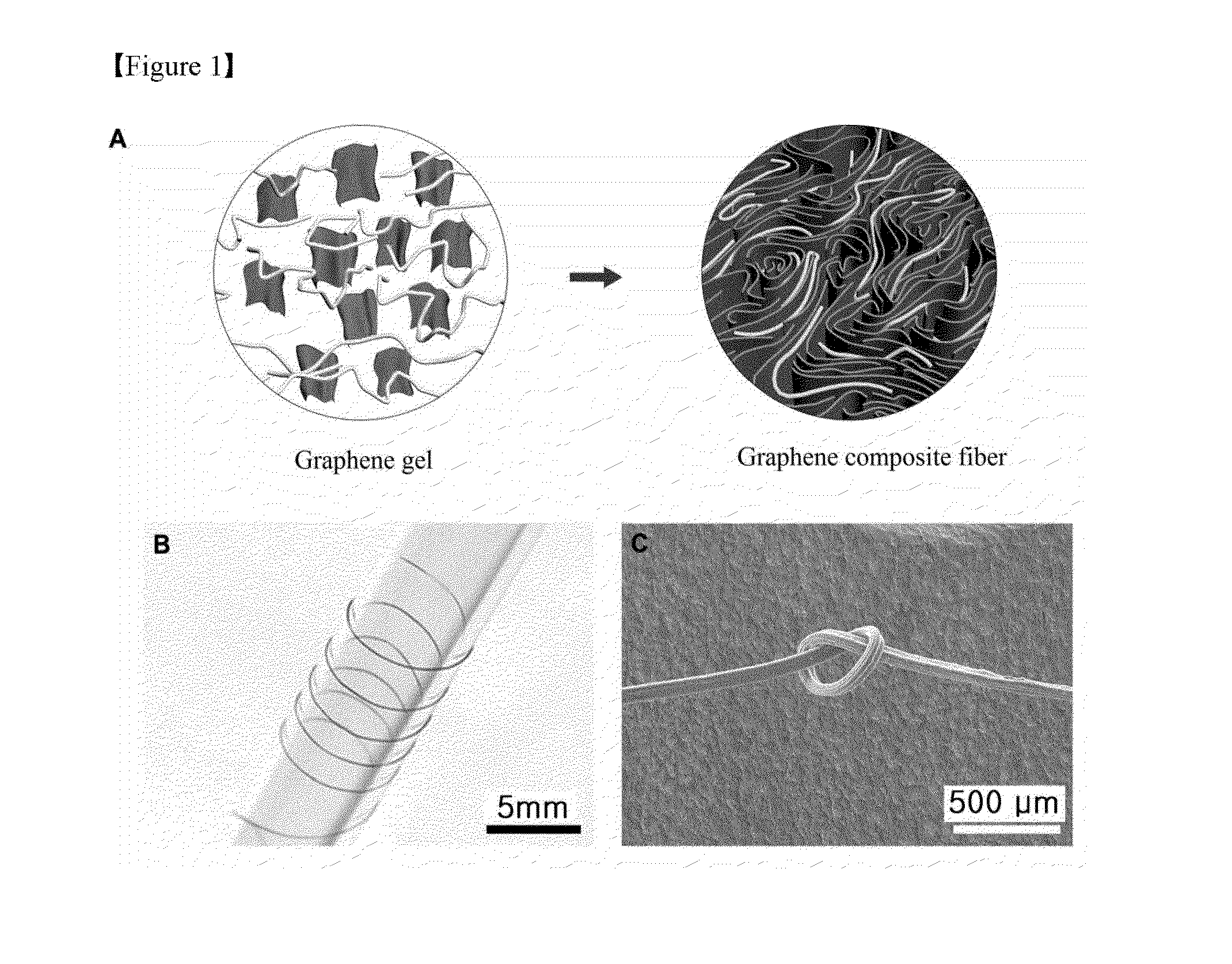

[0045]In accordance with the method illustrated in FIG. 1, RCCG was dispersed in dimethylformamide (DMF) in the presence of an appropriate amount of triethylamine to obtain a stable graphene dispersion. Several grams of RCCG was obtained by reducing an aqueous dispersion of CCG with excess hydrazine at 95° C. over 2 h in accordance with previously reported methods (Li, D., Muller, M. B., Gilje, S., Kaner, R. B. & Wallace, G. G. Processable aqueous dispersions of graphene nanosheets. Nature Nanotech. 3, 101 (2008)). As a result of the reduction reaction, the graphene aggregated in the aqueous solution. The graphene aggregates were acidified with dilute sulfuric acid under vigorous stirring to a pH of 2 or less, and transferred to a sintered funnel. The aggregates were washed with a large amount of Milli-Q water on the funnel until the pH reached about 7. The filtered material was dried under vacuum at 70° C. ...

example2

Production of Graphene Flakes / PVA Composite Fiber

[0046]The solvent (DMF) of the graphene flake dispersion was exchanged with distilled water by centrifugation. The G / F aqueous solution was mixed with sodium dodecyl benzene sulfonate (SDBS) by ultrasonication.

[0047]The graphene dispersion was slowly injected into a coagulation bath containing PVA (molecular weight=89,000-124,000, degree of hydrolysis=˜99%) through a syringe (26 gauge) and wet spun to continuously produce a uniform graphene / PVA fiber.

[0048]After dipping in a coagulation bath for one day, the graphene / PVA fiber was thoroughly washed with distilled water and vertically dried in air at room temperature. The graphene / PVA fiber was annealed at 150° C. and dipped in methanol for 8 h to obtain thermally drawn, methanol-treated GF / PVA. The annealing and methanol treatment increased the crystallinity of the PVA.

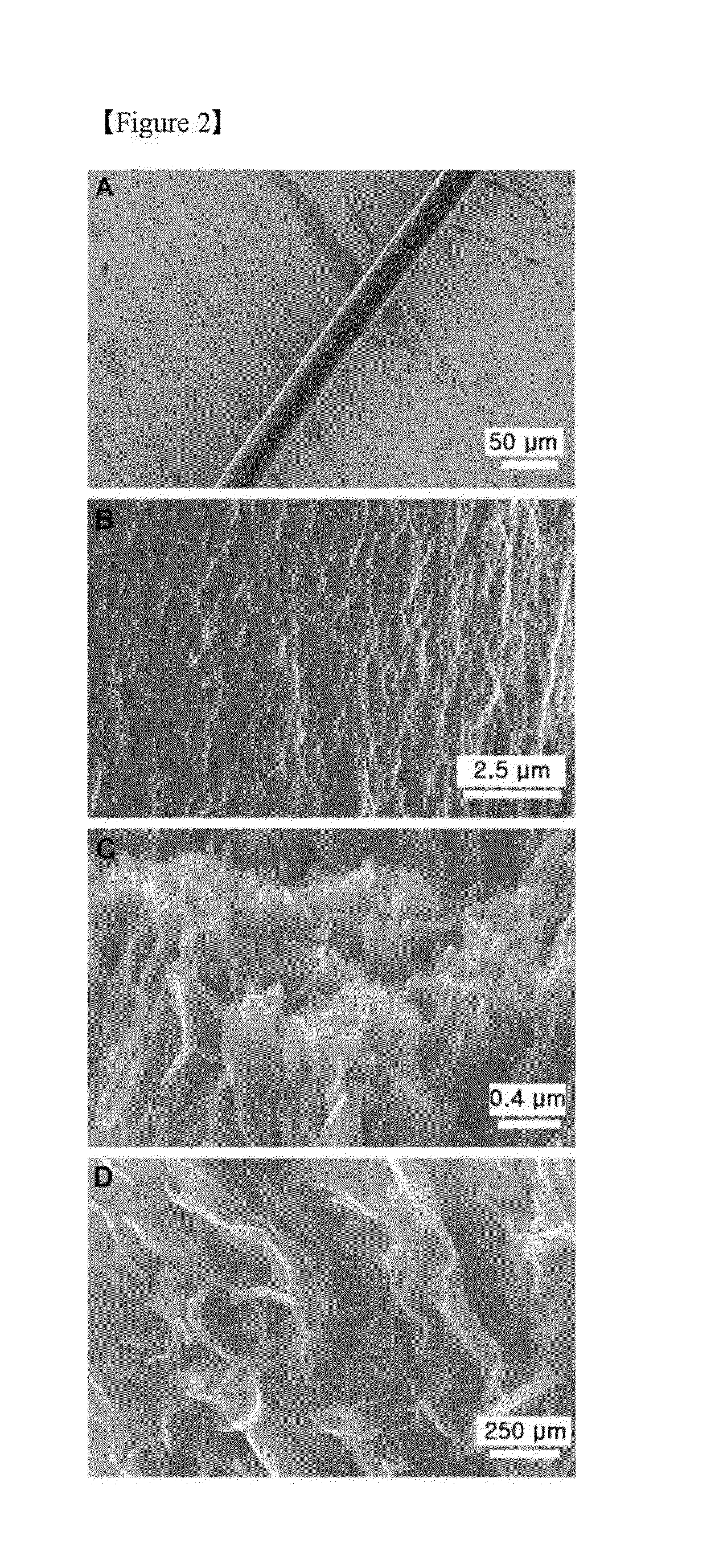

[0049]Experimental Example: Characterization of the Graphene Composite Fiber

[0050]The graphene composite fiber was su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| toughness | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com