Corrugated Tube Regenerator for an Expansion Engine

a technology of expansion engine and regenerative heat exchanger, which is applied in the direction of indirect heat exchangers, machines/engines, lighting and heating apparatus, etc., can solve the problems of low capacity gas turbines that are generally considered impractical, limited to constant speed proto-types, and ongoing gas turbine development. , to achieve the effect of low seal leakage, low leakage, and increased pressure capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

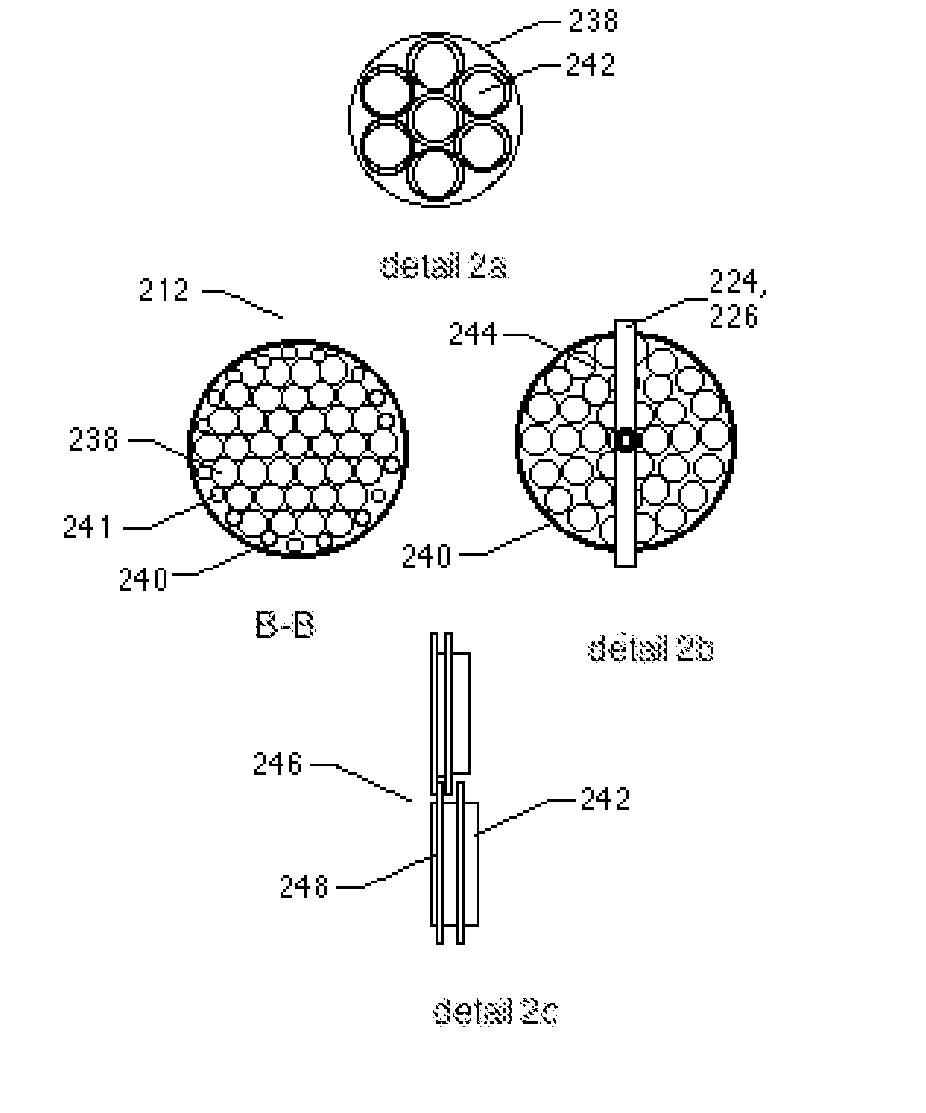

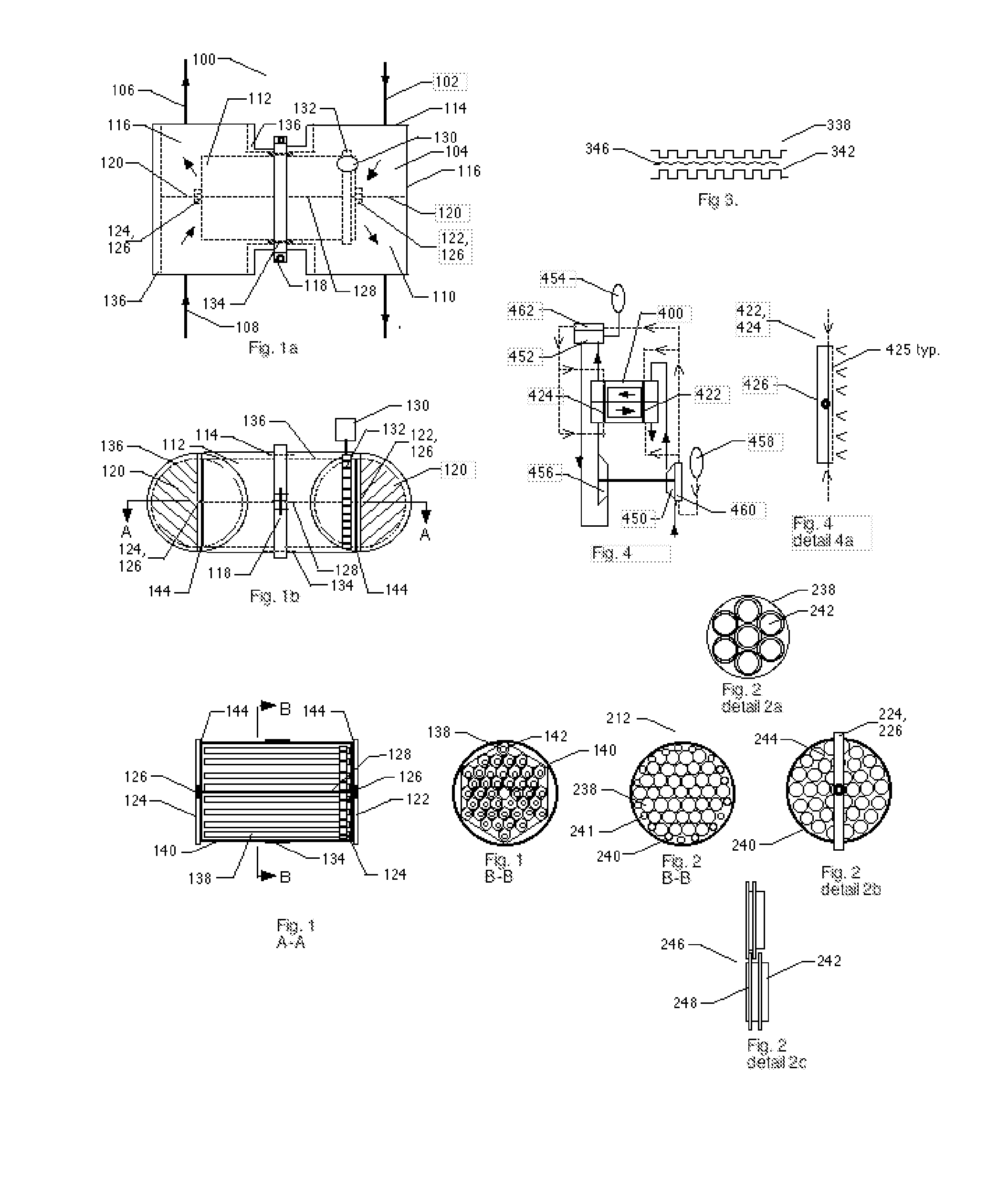

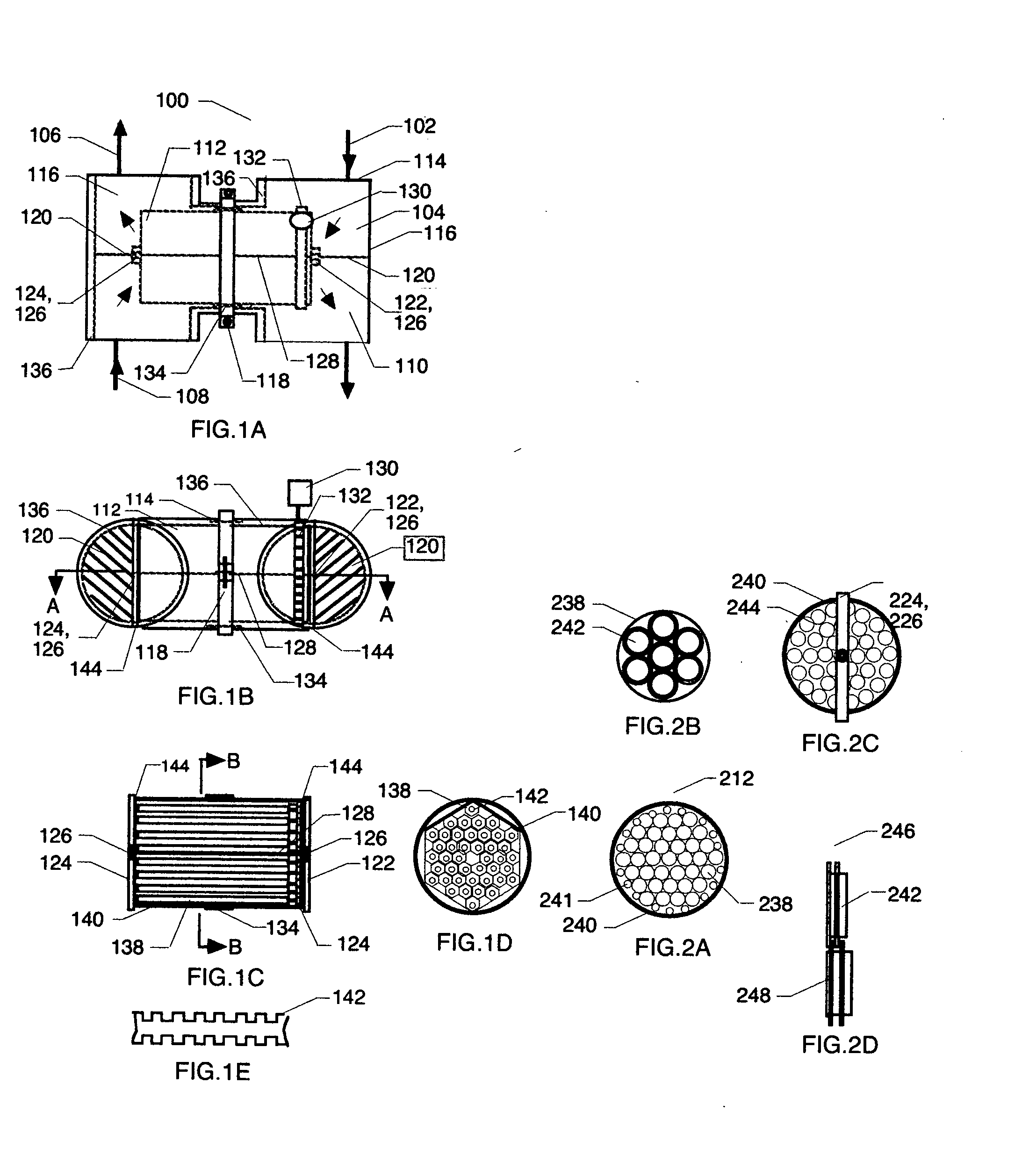

[0029]FIG. 1A and FIG. 1B illustrate working fluid channeling and component arrangement of a preferred embodiment of a rotary regenerator 100 of a prime mover of the present invention. Arrows indicate flow direction of working fluid from a compressor discharge line 102 through a pressurized regenerator channel 104 and discharging to a combustor intake line 106, while working fluid exhaust from a turbine discharge line 108 continues through a depressurized regenerator channel 110 to atmosphere. Heat is transferred from the turbine exhaust to pressurized working fluid within a rotating heat transfer matrix 112. The matrix is contained and supported in a containment vessel 114 constructed of two tee fittings 116 held together by a bolted clamp 118. Clamped stainless steel tee fittings are available from Victaulic Company of Easton, Pennsylvania. Semi-circular baffle plates 120, welded to the fittings and abutted to a colder matrix end support bar 122 and to a hotter matrix end support ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| cruising speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com