Integrated and modular approach for converting electrical power to ionic momentum and high differential voltage potential

a technology of electrical power and ionic momentum, applied in the field of renewable energy and environmental contaminant remediation, can solve the problems of less ability to conduct this accumulating heat and increase heat, and achieve the effects of reducing the number of electrical power generating devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

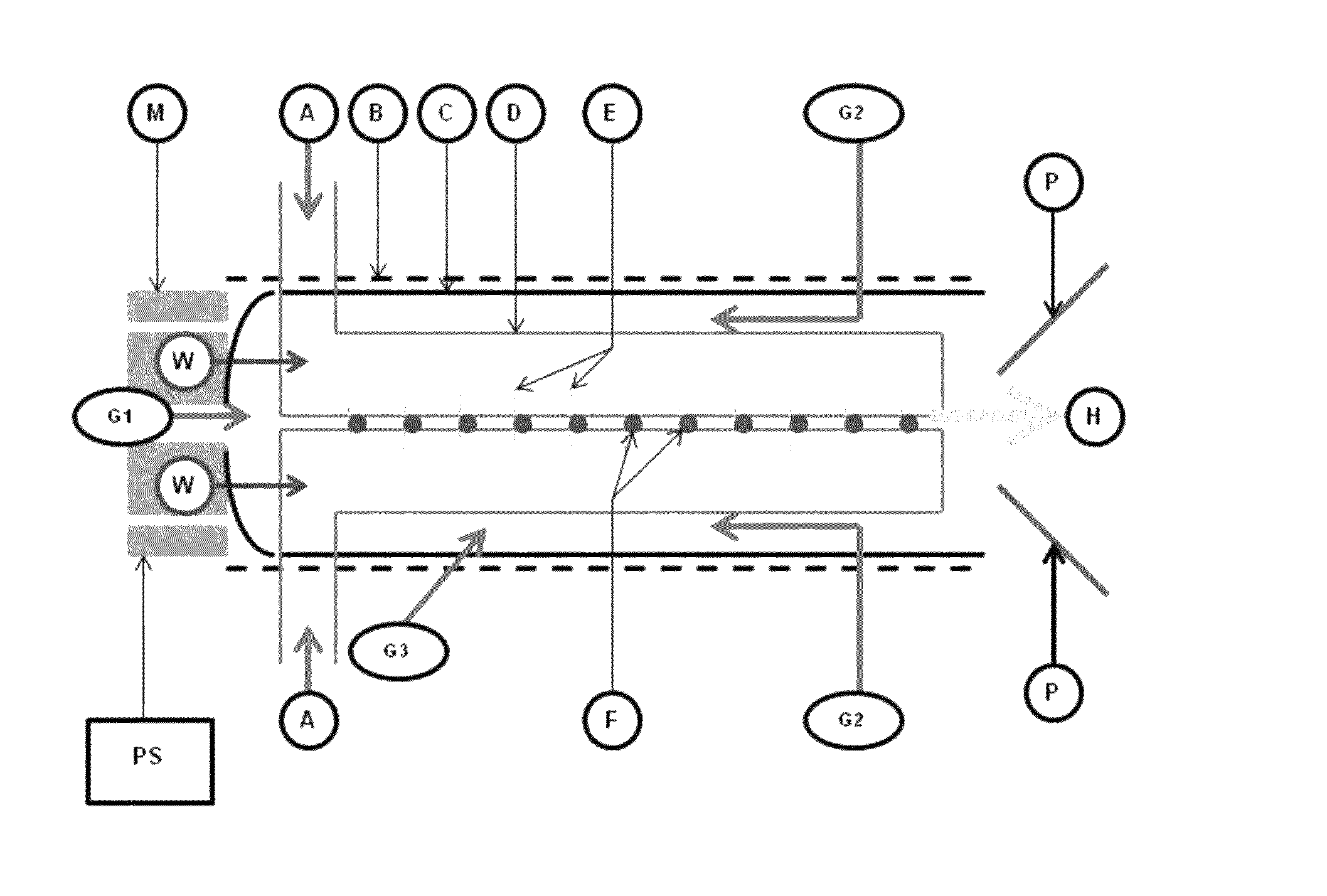

[0048]FIG. 1 is a diagram illustrating the fundamental configuration of the apparatus. A magnetron or array of magnetrons (M) is arranged at the end of a cylindrical shield (B) such that, when energized, microwaves (W) propagate into the cylinder (to the right, or, positive Z direction). The cylindrical shield (B) is constructed of metal or other shielding material and lined with refractory material to protect it from high temperatures. Within this cylindrical shield an open ended, radio transparent nozzle (C) is placed such that as microwaves (W) propagate into the cylinder they do so unobstructed, passing through the nozzle (C) but are constrained by the cylindrical shield (B). A pair or a series or a series of pairs of spheres, or, a pair or a series or a series of pairs of cylinders (shown, D) are micro-perforated and arranged within the nozzle (C) such that the micro-perforations oppose each other (E) and are separated by a variable air gap. These cylinders (or spheres) are com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com