Method for semiconductor selective etching and bsi image sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

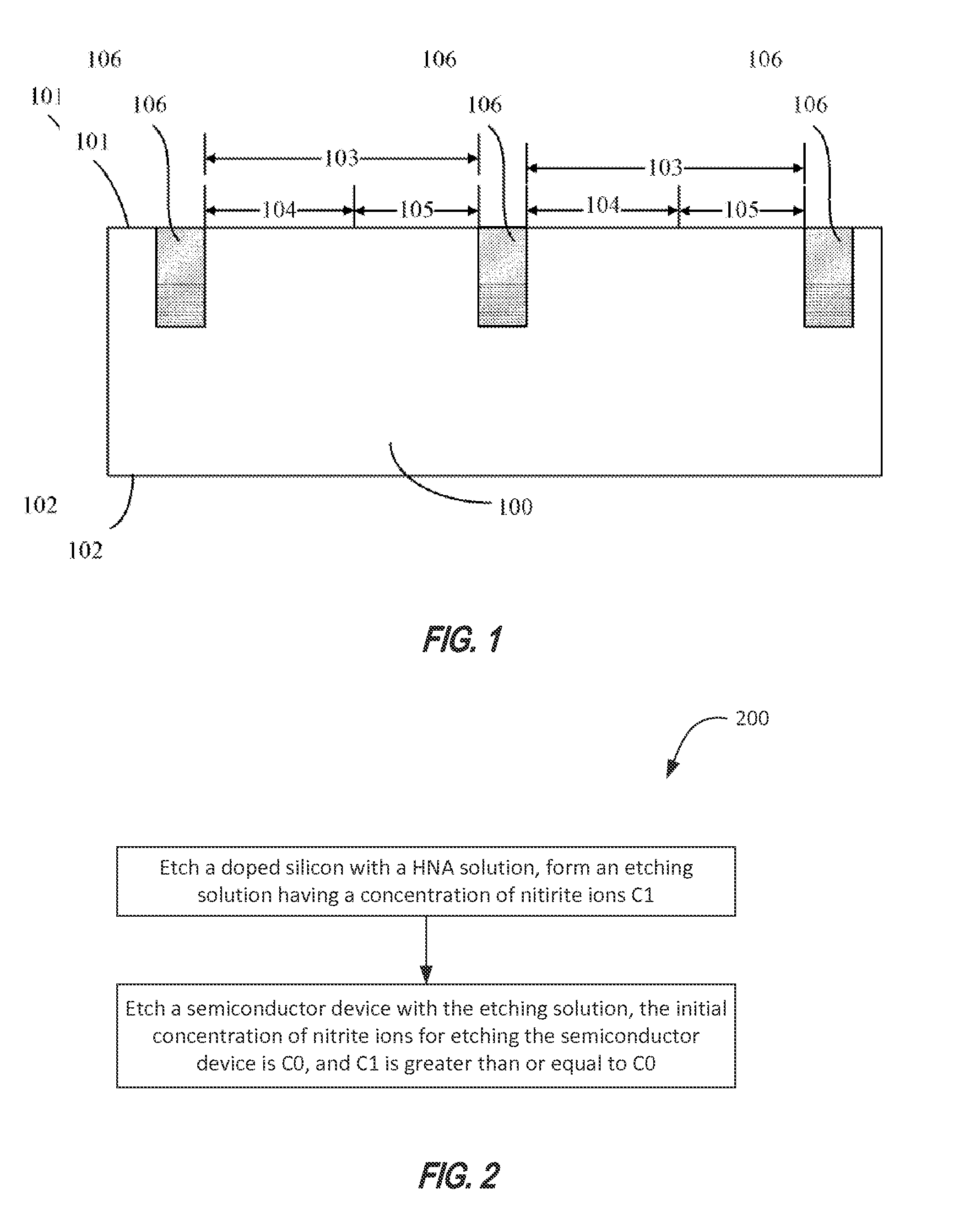

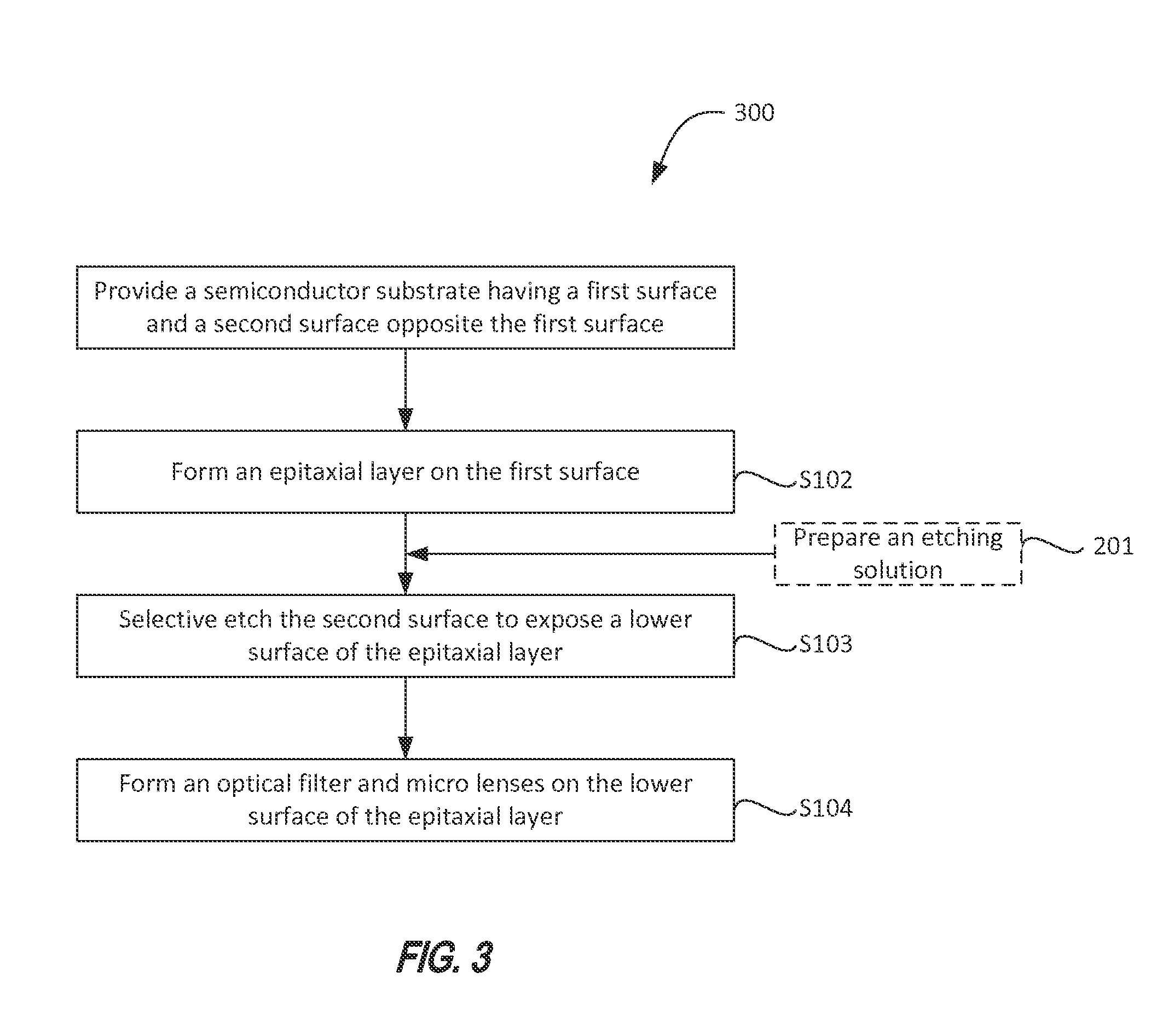

[0042]1. Etching Solution Preparation

[0043]A P-type silicon substrate is provided. The silicon substrate has a resistivity in the range of 0.006 to 0.01 Ω·cm and is doped with a doping concentration higher than 1×1018 atoms / cm3. The silicon substrate is then submitted to marking, cleaning, back-grinding, flipping, chemical mechanical polishing, and the like. An HNA solution is sprayed onto the silicon substrate and evenly distributed on the surface of the silicon substrate through a low rotation speed (3, and CH3COOH in a volume ratio of 1:3:8, the mass concentration percentage of HF is 49%, the mass concentration percentage of HNO3 is 70%, and the mass concentration percentage of CH3COOH is 100%.

[0044]During the rotation, the proportion of HNO2 in the HNA solution gradually increases. The etching process stops when the etch rate reaches a stable value, and an etching solution is obtained from the HNA solution. A process for determining the etch rate can include measuring the thickn...

example 2

[0054]1. Etching Solution Preparation

[0055]A P-type silicon substrate is provided. The silicon substrate has a resistivity in the range of 0.01 to 0.02 Ω·cm and is doped with a doping concentration higher than 1×1017 atoms / cm3. The silicon substrate is then submitted to marking, cleaning, back-grinding, flipping, chemical mechanical polishing, and the like. An HNA solution is sprayed onto the silicon substrate and evenly distributed on the surface of the silicon substrate through a low rotation speed (3, and CH3COOH in a volume ratio of 5:1:4, the mass concentration percentage of HF is 49%, the mass concentration percentage of HNO3 is 70%, and the mass concentration percentage of CH3COOH is 100%. The etch rate can be determined using the same processes as described in Example 1 above and are denoted S3.

[0056]2. Testing the Etch Rate of the Etching Solution

[0057]The etch rates of the etching solution are measured using the same P-type silicon substrates. The P-type silicon substrates...

example 3

[0066]1. Etching Solution Preparation

[0067]An N-type silicon substrate is provided. The N-type silicon substrate has a resistivity in the range of 0.05 to 0.08 Ω·cm and is doped with a doping concentration higher than 1×1016 atoms / cm3. The N-type silicon substrate is then submitted to marking, cleaning, back-grinding, flipping, chemical mechanical polishing, and the like. An HNA solution is sprayed onto the silicon substrate and evenly distributed on the surface of the silicon substrate through a low rotation speed (3, and CH3COOH in a volume ratio of 3:5:2, the mass concentration percentage of HF is 30%, the mass concentration percentage of HNO3 is 60%, and the mass concentration percentage of CH3COOH is 80%. The etch rate can be determined using the same processes as described in Example 1 above and are denoted S5.

[0068]2. Testing the Etch Rate of the Etching Solution

[0069]The etch rates of the etching solution are measured using same N-type silicon substrates. The N-type silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com